Clamping device for workpiece air tightness inspection

An air-tightness inspection and clamping device technology, applied in workpiece clamping devices, liquid/vacuum measurement for liquid-tightness, manufacturing tools, etc. and other problems, to achieve the effect of solving sealing difficulties, safe and reliable clamping, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

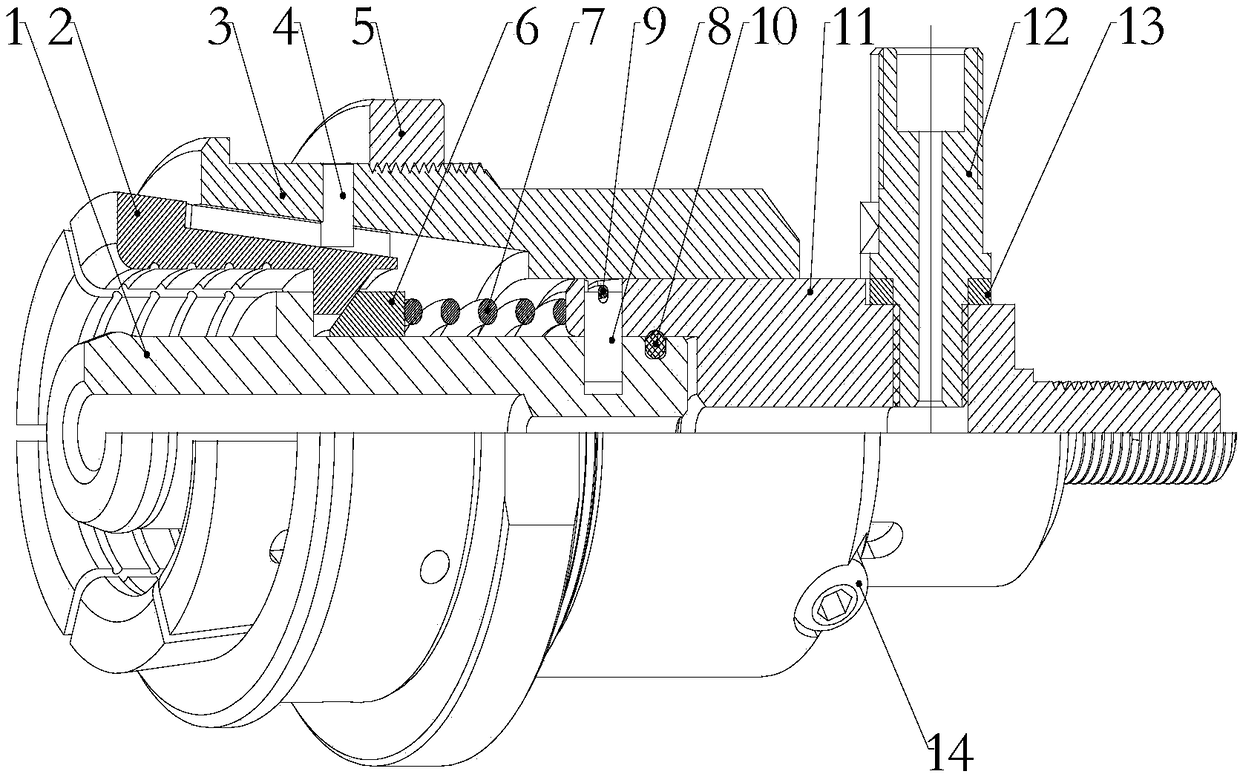

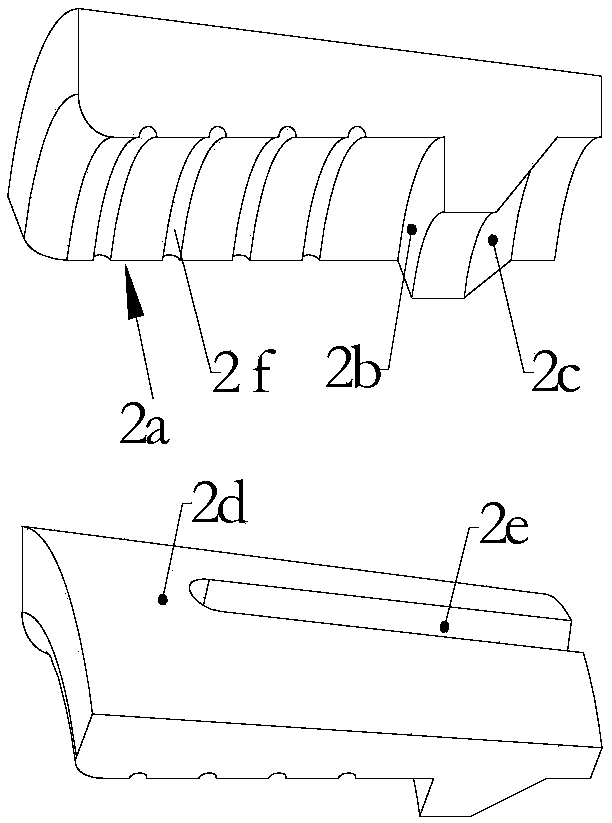

[0032] The clamping device for workpiece air tightness inspection of the present invention comprises: a hollow shaft 1, a sliding rod 11, a clamping mechanism 2, a sliding sleeve 6, a compression reset part 7, a pressing sleeve 3, and a driving mechanism, and the bottom faces between them. The relationship is described in detail:

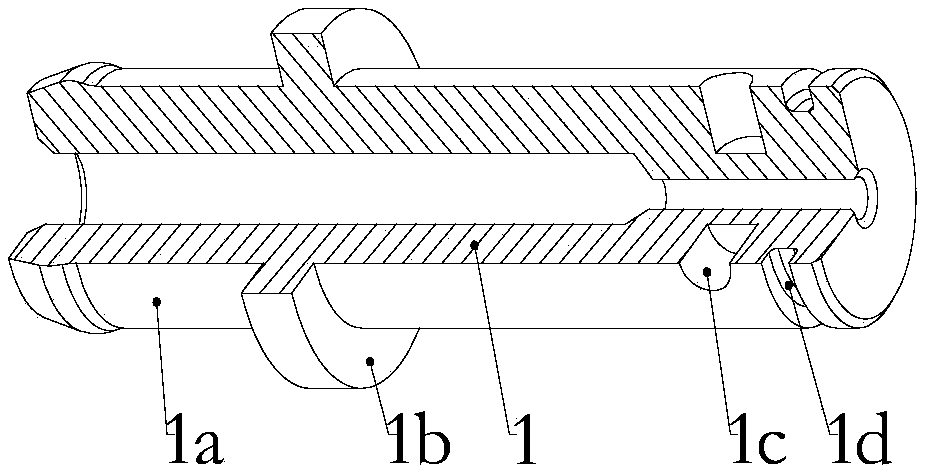

[0033] Such as figure 1 and figure 2 As shown, the outer peripheral surface 1a of one end of the hollow shaft 1 is provided with a first limiting portion 1b, and the first limiting portion 1b is an annular protrusion; the outer peripheral surface of the other end of the hollow shaft 1 is provided with an assembly hole 1c and the first annular groove 1d, the sealing ring 10 is installed in the first annular groove 1d.

[0034] One end of the sliding rod 11 is provided with a ventilation hole, and after the end of the sliding rod 11 provided with the ventilation hole is fixedly connected with the hollow shaft 1, the ventilation hole on the sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com