Motor shaft surface coating structure applied to power tool turret

A surface coating, power turret technology, applied in the tool holder accessories, electromechanical devices, electrical components and other directions, can solve problems such as damage, entering the bearing and motor inside the headstock, to extend the service life and enhance the bearing capacity , the effect of excellent lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

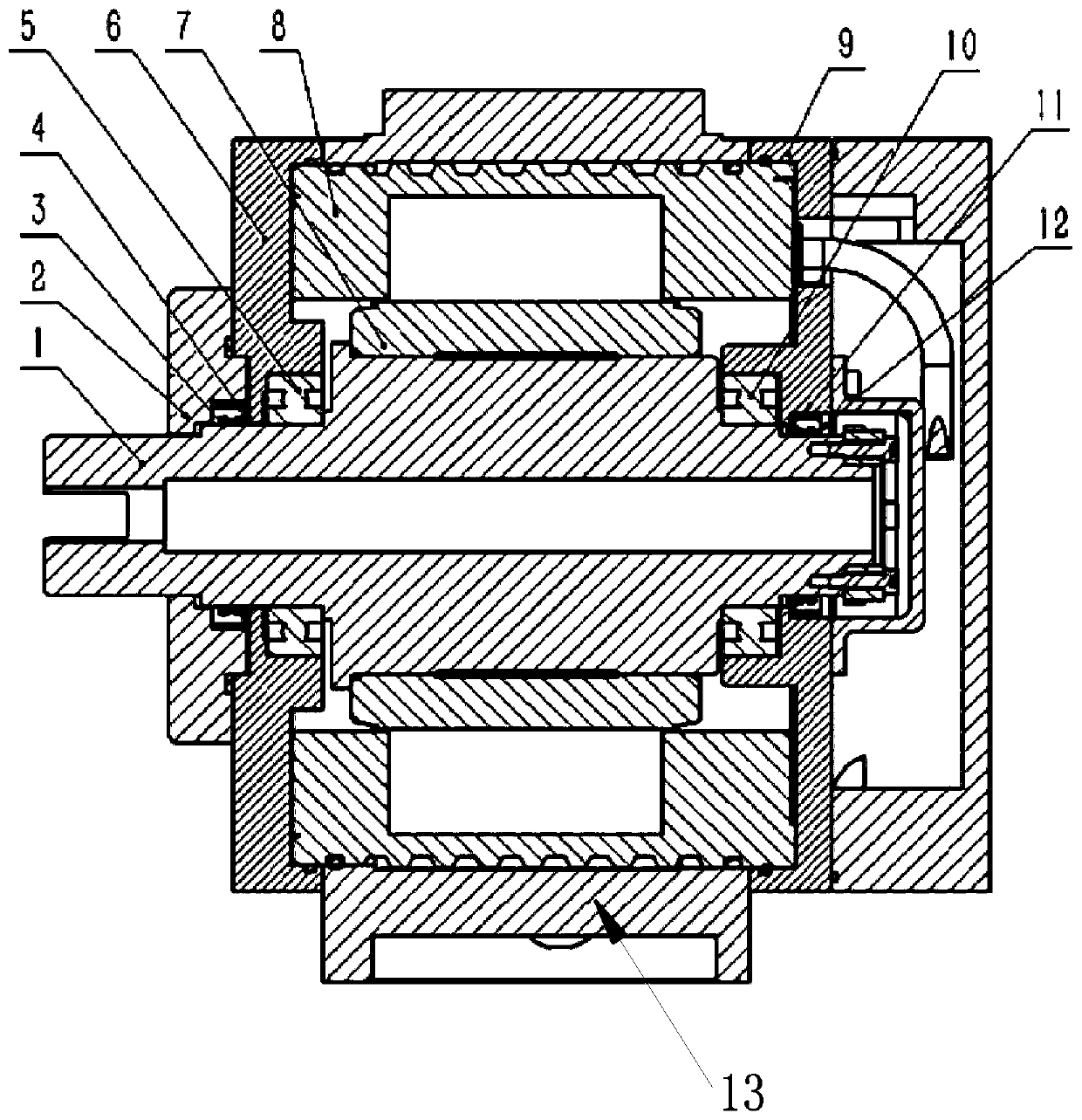

[0027] Such as figure 1 As shown, a motor shaft surface coating structure for a power turret provided in this embodiment includes a main shaft 1, a front bearing 5 and a rear bearing 10 assembled on both sides of the main shaft 1, and the main shaft 1 is composed of front bearings 5 at both ends. Supported with the rear bearing 10 and form an axial positioning, the outer sides of the front bearing 5 and the rear bearing 10 are respectively connected with the front flange 6 and the rear flange 9; the front flange 6 and the rear flange 9 are installed on the headstock 13 both ends; the outer side of the front flange 6 is equipped with an end cover 2, and the front oil seal 4 and the rear oil seal 11 are respectively installed in the end cover 2 and the rear flange 9; the oil seal lips of the front oil seal 4 and the rear oil seal 11 are connected with the The outer circle of the main shaft 1 contacts and slides, and the contact areas between the main shaft 1 and the front oil ...

Embodiment 2

[0034] Front wear-resistant coating 3 and rear wear-resistant coating 12 in the present embodiment are MoS2 coating; Because MoS2 coating has very high binding force, coating is dense, seamless, even under impact or collision also can Ensure that the coating does not fall off, does not peel off, and is firmly bonded. The hardness can reach 7H and the service life is long.

[0035] MoS2 coating has excellent lubricity, compression resistance, corrosion resistance, low temperature and thermal stability, etc., and is resistant to fatigue wear, erosion wear, abrasive wear, and adhesive wear.

[0036] The friction coefficient of MoS2 coating can be as low as 0.06-0.08, which can prevent the bite, reduce resistance, wear, and seizure between parts. It is applicable to a wide range of temperature, load and speed, and it performs particularly well in high-load applications. .

[0037]The MoS2 coating can withstand a high temperature of 400°C, and will not cause peeling, cracking, dis...

Embodiment 3

[0041] The front wear-resistant coating 3 and the rear wear-resistant coating 12 in this embodiment are a kind of in titanium nitride coating, titanium carbide nitride coating and chromium nitride coating; The direct contact between metals on the inner wall of the oil seal can have a good initial wear reduction effect and prolong the service life of the main shaft; at the same time, the wear-resistant coating also helps to enhance the bearing capacity of the main shaft; specifically, in this embodiment, The thickness of the front wear-resistant coating 3 and the rear wear-resistant coating 12 is 4 μm.

[0042] For other contents of this embodiment, reference may be made to Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com