Complex tubular component flexible forming device and method based on magnetorheological elastomer

A magnetorheological elastomer and flexible forming technology, which is applied in the field of high-pressure bulging of pipes, can solve the problems of poor sealing effect of liquid media, difficult local pressure control, and complicated equipment, so as to achieve less environmental pollution, avoid easy cracking, and improve wall thickness. The effect of thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

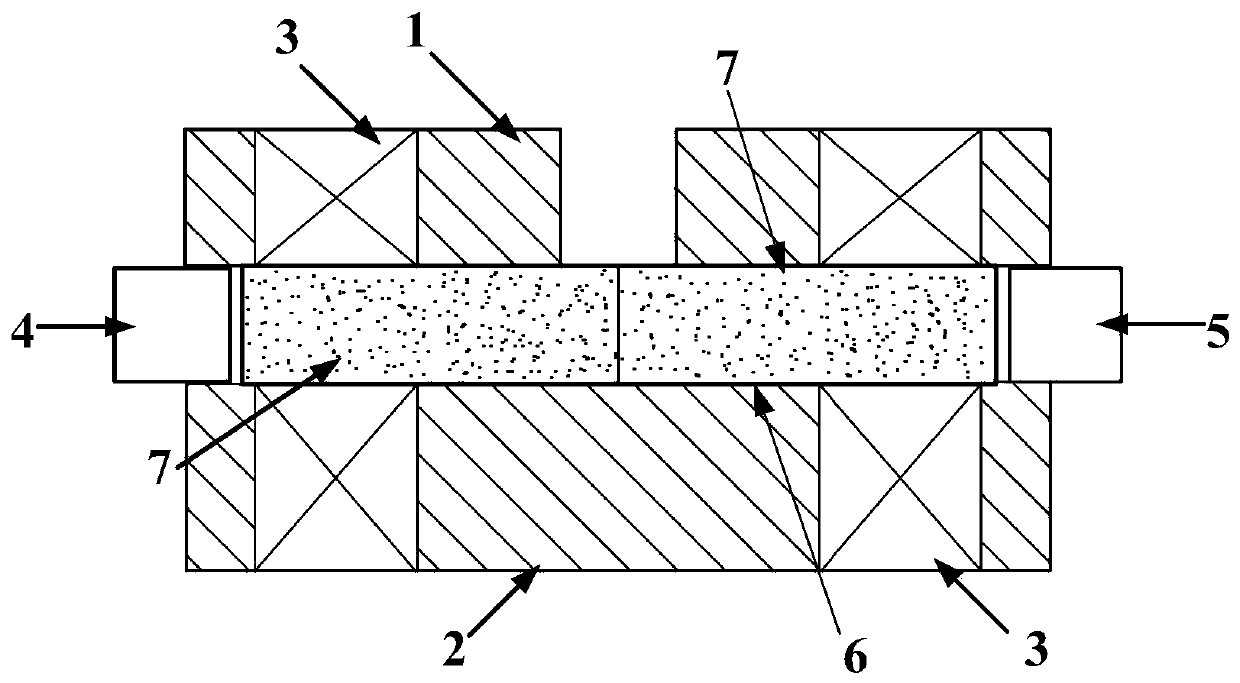

[0036] The flexible forming method of a complex component based on magnetorheological elastomer of the present invention includes the following steps:

[0037] First, place the tube blank to be formed between the lower surface of the upper mold and the upper surface of the lower mold, and clamp the tube blank to be formed; the selected magnetorheological elastomer uses polyurethane rubber as the matrix and carbonyl iron powder as the magnetic particles , Put the two sections of the magnetorheological elastomer into the tube blank from both ends of the tube blank. The magnetorheological elastomer should fill the tube blank. Insert the left and right punches into the upper and lower molds from both sides, and Not in contact with the tube blank, such as figure 1 ;

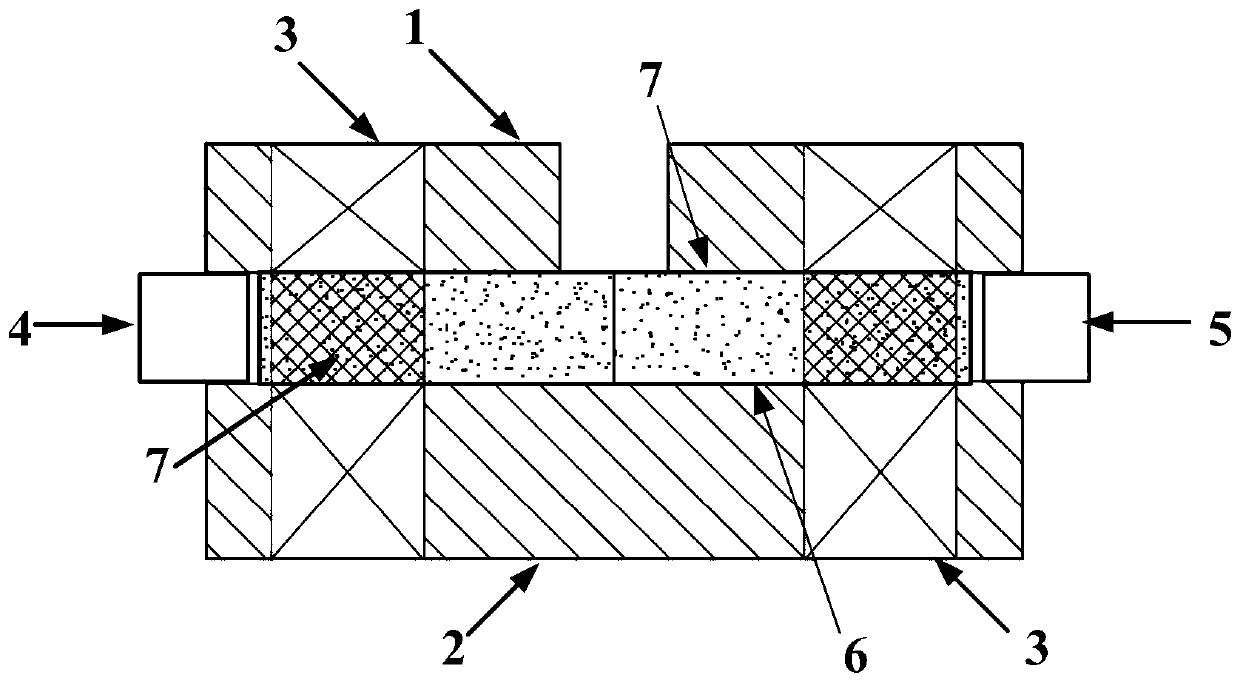

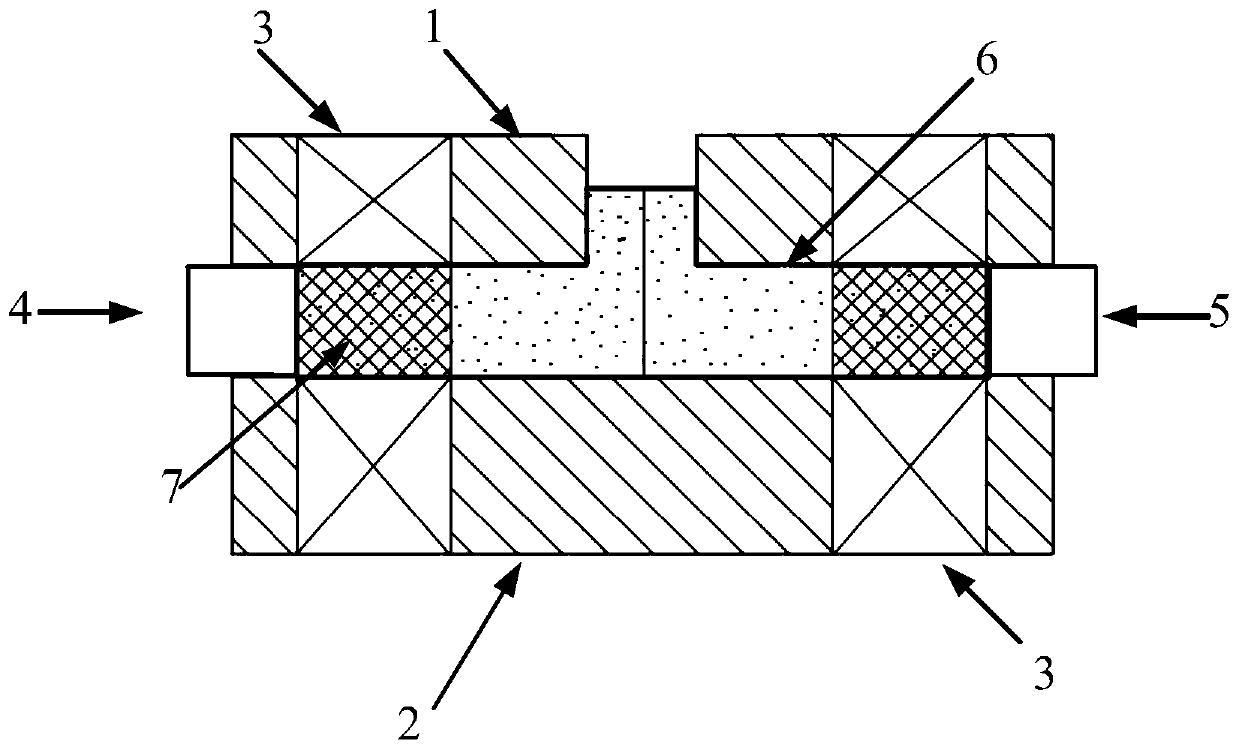

[0038] Secondly, determine the required magnetic induction intensity B according to the material of the tube to be formed and the elastic modulus of the magnetorheological elastomer required in the forming stage. The magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com