Tube-type solid oxide fuel cell monocell and preparation method thereof

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve problems such as high temperature sealing difficulties, and achieve the effects of sealing and sintering, easy assembly and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below through specific examples.

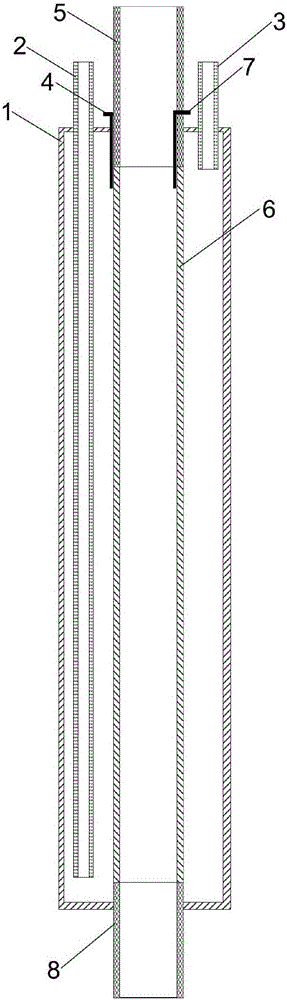

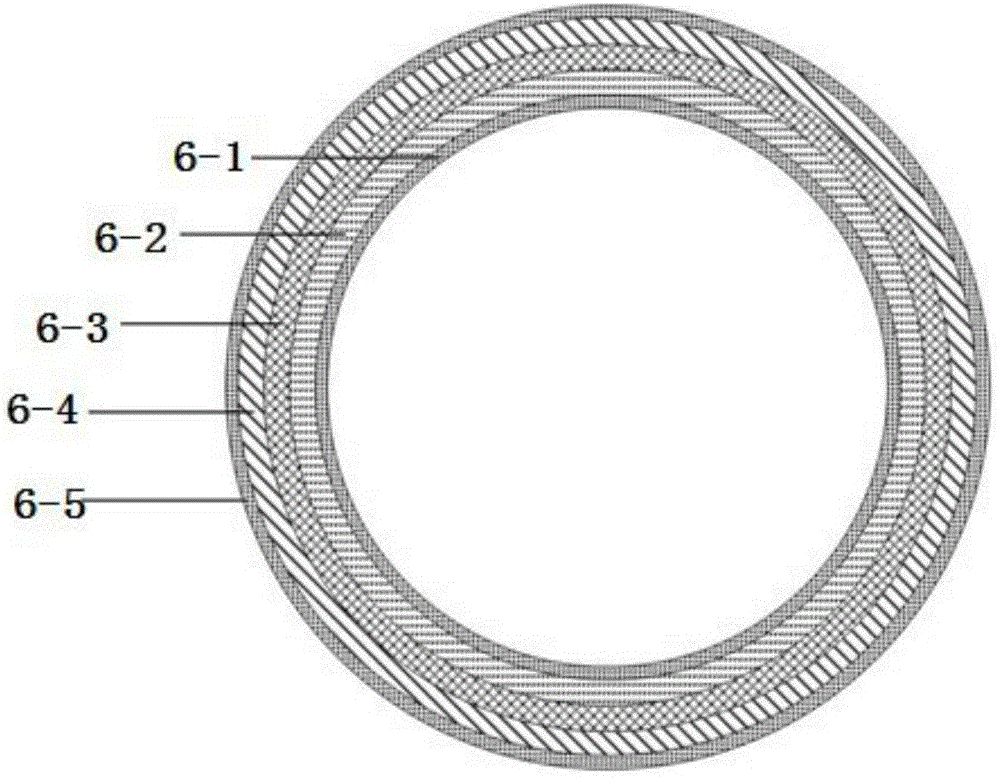

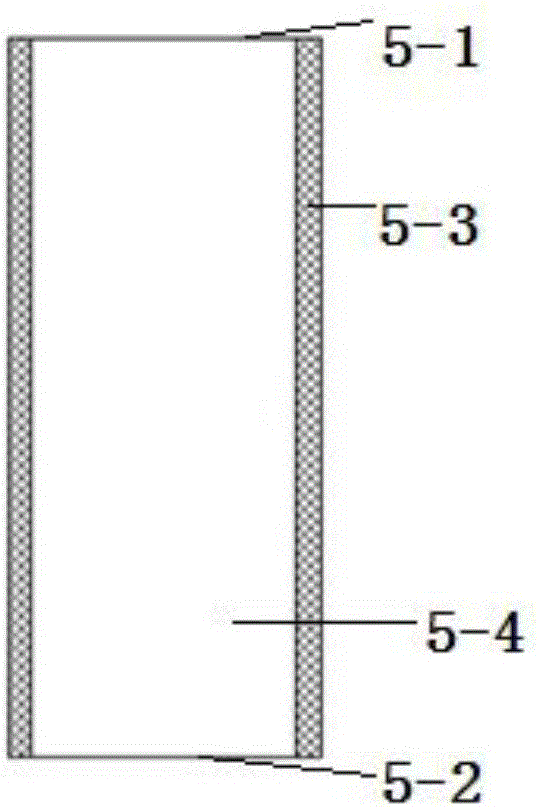

[0025] like figure 1 As shown, a single tubular solid oxide fuel cell, 1 is the cathode shell, 2 is the cathode air intake pipe, 3 is the cathode air outlet pipe, 4 is the cathode terminal, 5 is the connector on the fuel cell power generation tube body, and 6 is the The fuel cell power generation tube body, 7 is the anode terminal, and 8 is the lower joint of the fuel cell power generation tube body, wherein:

[0026]A fuel cell power generation pipe is arranged in the cathode casing, the length of the fuel cell power generation pipe is shorter than the cathode casing, a cathode air intake pipe and a cathode gas outlet pipe are arranged between the cathode casing and the fuel cell power generation pipe, and one end of the cathode air intake pipe is arranged at On the outside of the cathode casing, the other end of the cathode air intake pipe extends near the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com