Method for measuring trace element content in aluminium alloy by ICP method

A technology of medium and trace elements and aluminum alloy, which is applied in the field of analysis and detection, can solve the problems of low atomization efficiency, incomplete dissolution, and few types of elements, and achieve the effects of less reagent consumption, high analysis efficiency, and reduced matrix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Taking the GSB04-2191-2008ZBY5031 aluminum alloy standard sample as a sample, the multi-element content was determined.

[0023] (1) Sample dissolution preparation: Weigh 0.2000g of GSB04-2191-2008ZBY5031 aluminum alloy standard sample into a polytetrafluoroethylene beaker, add 15ml of the mixed solution, cover with a watch glass, control the temperature ≤ 60 ℃ and slowly heat until the reaction is complete , Remove the beaker and wait for the solution to cool, then slowly add 1ml of hydrofluoric acid dropwise and shake the beaker until the sample is completely dissolved, transfer it to a 100ml volumetric flask, dilute the solution to the mark with water, and shake well.

[0024] (2) Determination of sample results: Measure the spectral intensity of each element in the GSB04-2191-2008ZBY5031 aluminum alloy standard sample solution, and calculate the content of each element in the solution to be tested from the calibration curve. The analysis results are co...

Embodiment 2-4

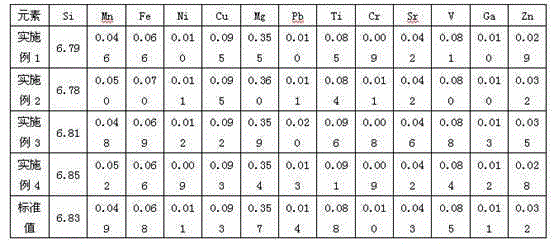

[0025] Embodiment 2-4: except the following difference, all the other are the same as embodiment 1: in embodiment 2, mixed solution 10ml, hydrofluoric acid 1ml; In embodiment 3, mixed solution 20ml, hydrofluoric acid 1.5ml; embodiment 4, mixed solution 15ml, hydrofluoric acid 0.5ml. The analytical results of each embodiment are compared with the standard values as shown in Table 1.

[0026] Table 1: The measurement results (wt%) of each embodiment

[0027]

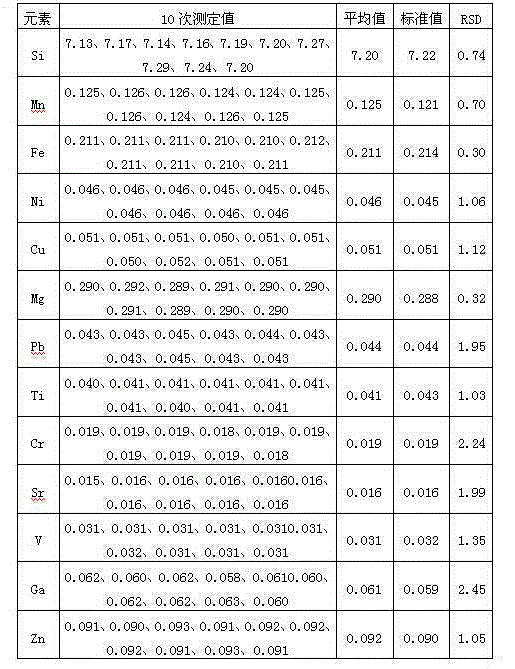

[0028] Precision test: take the GSB04-2191-2008ZBY5021 aluminum alloy standard sample as the sample, and measure its multi-element content.

[0029] (1) Sample dissolution preparation: Weigh five parts of 0.2000g GSB04-2191-2008ZBY5021 aluminum alloy standard samples into five polytetrafluoroethylene beakers, add 15ml of the mixed solution, cover with a watch glass, control the temperature ≤ 60 ℃ and slowly heat When the reaction is complete, remove the beaker and wait for the solution to cool, then add 1ml of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com