Metallic seal solvable bridge plug

A metal sealing and soluble bridge technology, used in sealing/isolation, wellbore/well components, earth-moving drilling, etc., can solve the problems of not easy to dissolve, block wellbore, large volume of soluble glue tube, etc., to improve friction force, good axial positioning effect, good axial positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

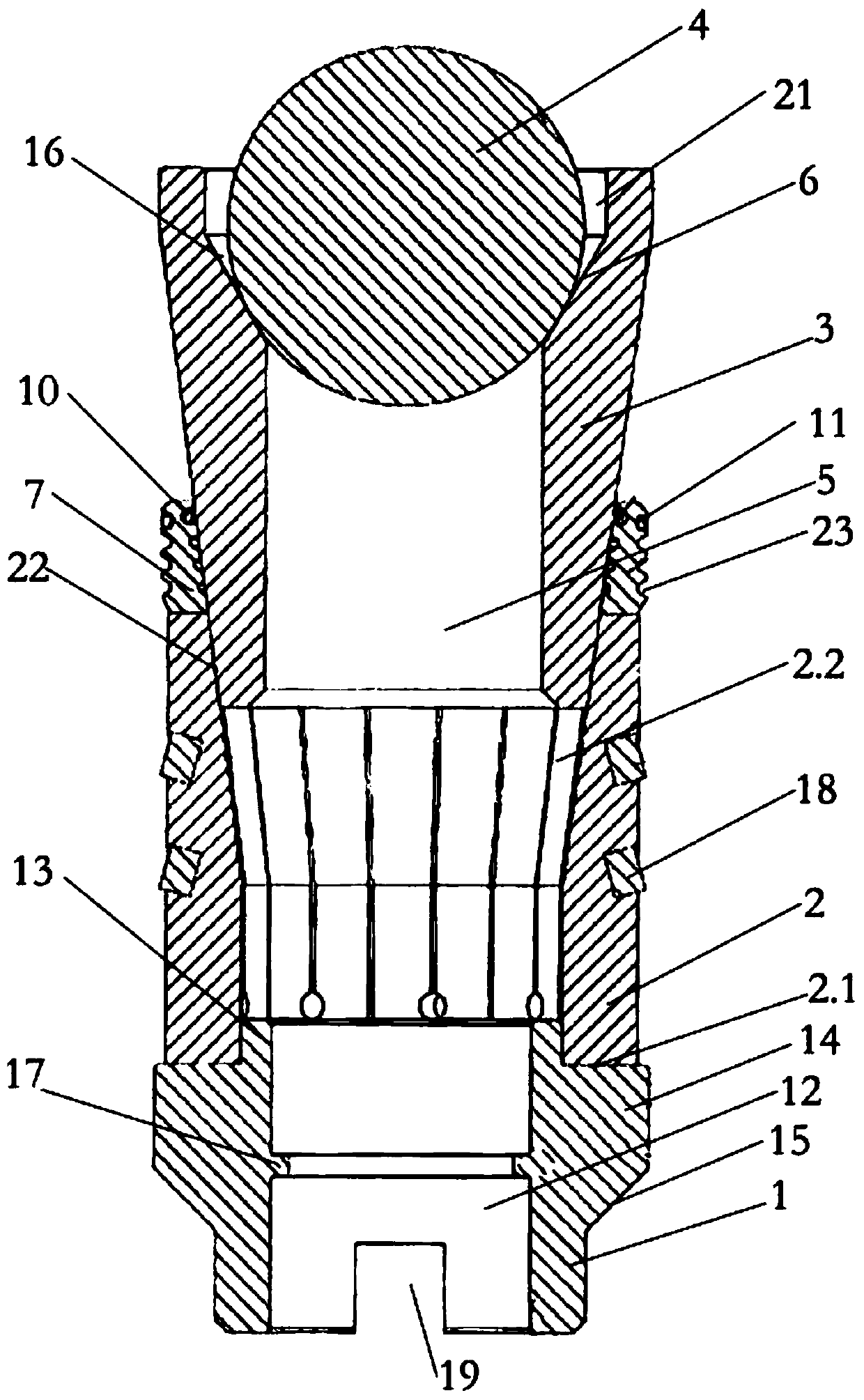

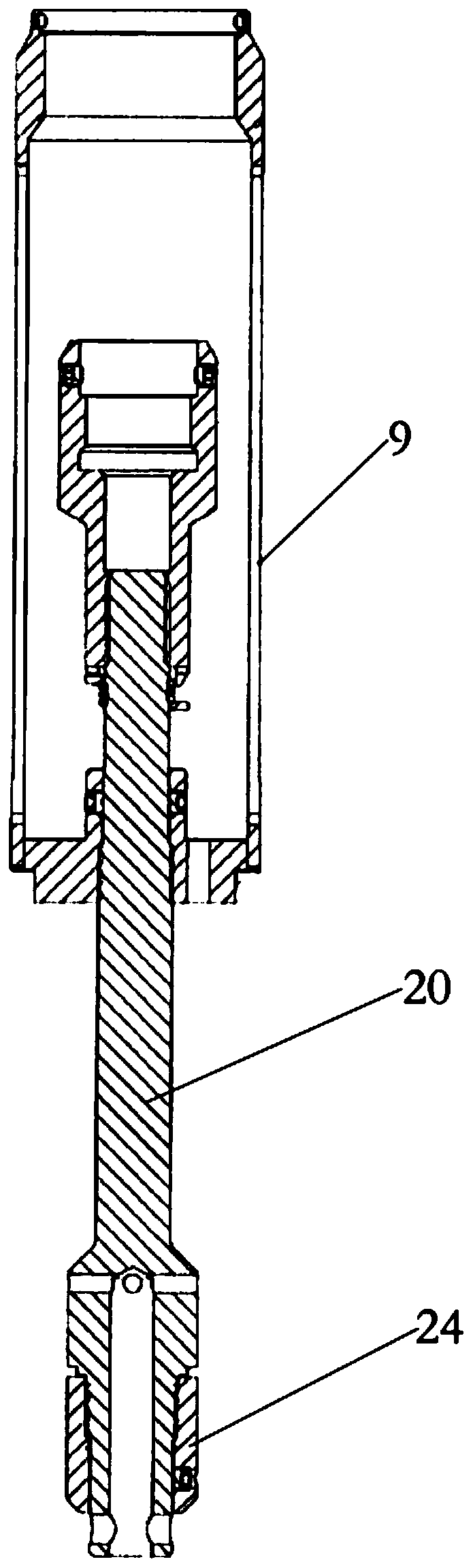

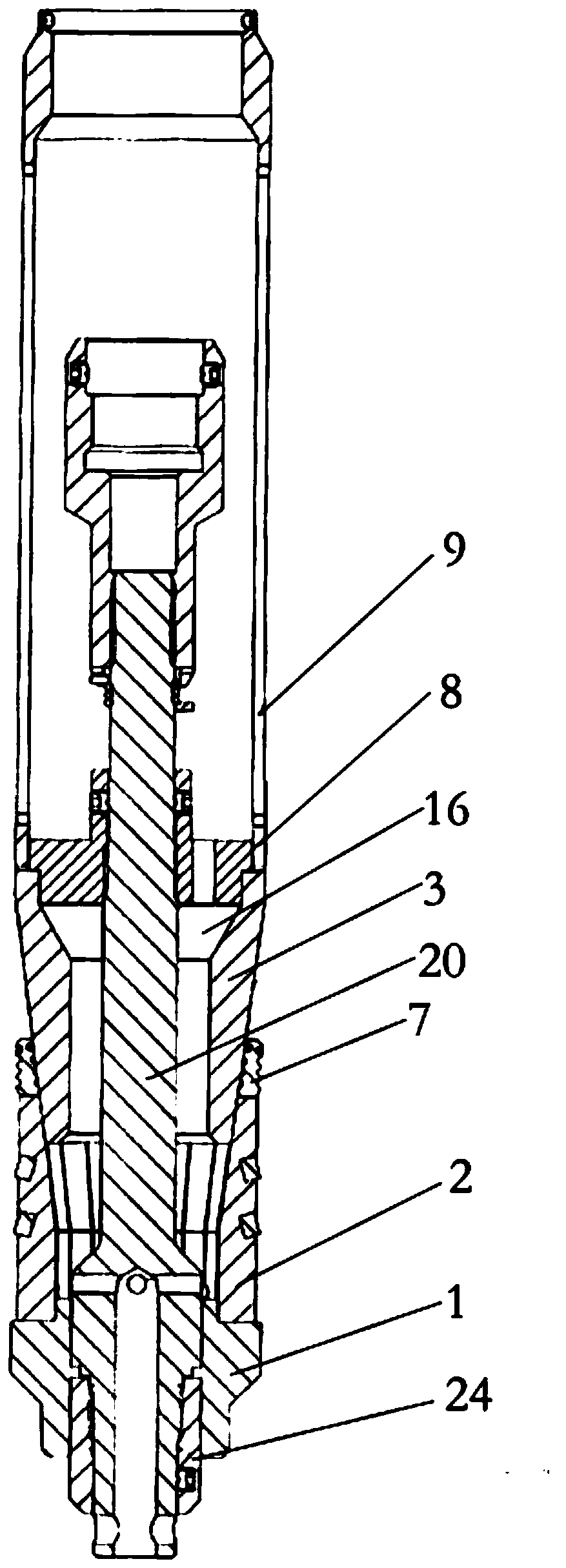

[0036] Such as Figure 1 to Figure 3 As shown, this embodiment provides a metal-sealed soluble bridge plug, including a lead 1, a slip 2, a ball seat 3 and a soluble ball 4, and the slip 2 includes an extruded end 2.1 that abuts against the lead 1 and The tapered extrusion cavity 2.2 closely matched with the outer wall of the ball seat 3, the leader 1, the slips 2 and the ball seat 3 are closely matched in turn to form a bridge plug body, the inside of the ball seat 3 communicates with the inside of the slip 2 to form a central hole 15, The central hole 5 is provided with a soluble ball support platform 6 that cooperates with the soluble ball 4 to achieve the sealing effect on the central hole 15; The upper end of the bridge plug abuts against, and the sealing mechanism 7 plays the role of sealing the annular space between the ball seat 3 and the casing in the well after the bridge plug setting is completed.

[0037] Because the outer wall of the ball seat 3 is closely matche...

Embodiment 2

[0042] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

[0043] In order to achieve a better sealing effect, the inner and outer walls of the sealing mechanism 7 are respectively provided with an inner sealing ring 10 and an outer sealing ring 11, which play a double sealing role and have high sealing reliability. There is an annular groove, and the inner sealing ring 10 and the outer sealing ring 11 are embedded in the corresponding annular groove.

[0044] Specifically, the inner and outer walls of the sealing mechanism 7 are provided with anti-slip lines, and the inner sealing ring 10 and the outer sealing ring 11 are both arranged on the inner and outer walls of the upper end of the sealing mechanism 7 .

[0045] The inner sealing ring 10 and the outer sealing ring 11 are made of soluble rubber or conventional insoluble rubber.

Embodiment 3

[0047] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 2.

[0048] The second center hole 12 inside the leader 1 communicates with the first center hole 5 and the axes of the two are consistent. The second center hole 12 is provided with a detachable fastening member for a detachable fixed connection with the adapter 9 .

[0049] Specifically, the upper end of the leader 1 is provided with an inner convex ring 13 and an outer boss 14, the outer diameter of the inner convex ring 13 is smaller than the outer diameter of the outer boss 14, and the inner convex ring 13 is close to the central hole 12 by the outer boss 14. The inner edge of the slips 2 extends vertically upwards, the extruding end 2.1 of the slip 2 is pressed against the outer boss 14, the outer diameter of the extruding end 2.1 is smaller than the outer diameter of the outer boss 14, and the inner convex ring 13 is located in the central hole-5 Inside, the minimum inner diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com