Sealing device

A sealing device, lip technology, applied in the direction of engine sealing, transportation and packaging, bearings, etc., to achieve the effect of improving the sealing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Embodiments of the present invention will be described below with reference to the drawings.

[0046] The sealing devices related to the various embodiments described below can be used as hub bearing seals (hub seals) in the bearing parts of automobile wheel suspension devices to prevent water and muddy water outside the bearing (outside the machine) A. , Salt water, dust, brake fluid or oil and other external foreign matter (interference factors) enter the bearing interior (machine) B, and at the same time, prevent the lubricating oil inside the bearing B from leaking to the bearing exterior A.

no. 1 example …

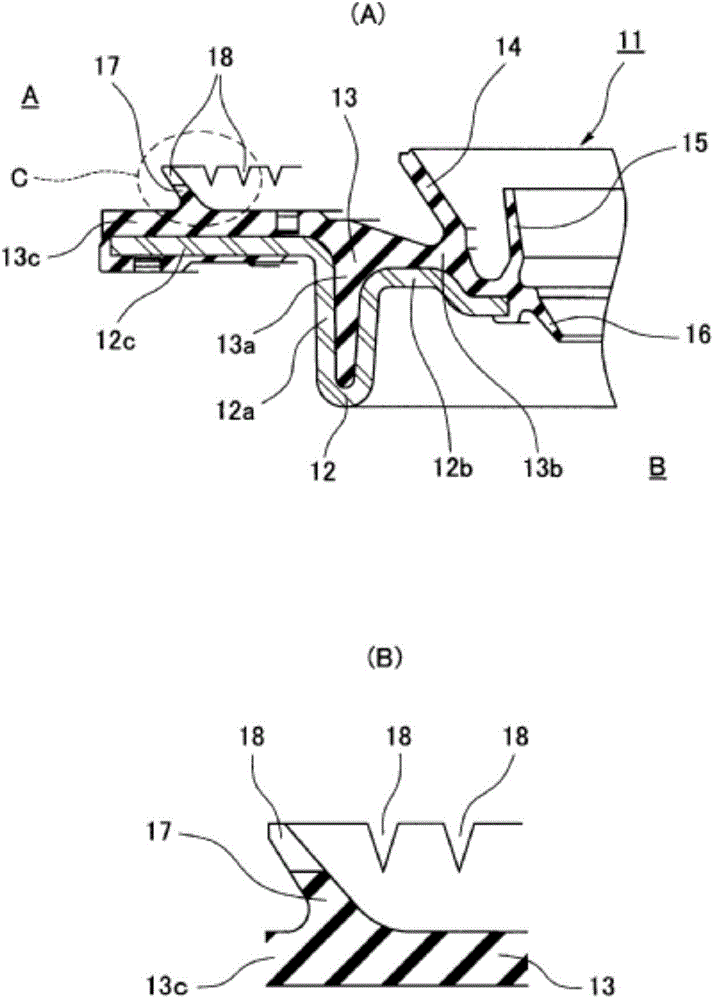

[0048] figure 1 The sealing device 11 shown in is provided with sliding lips 14, 15 for sealing so that foreign matter from the outside A does not enter the inside B of the machine, and a labyrinth lip that makes it difficult for foreign matter from the outside A to reach the sliding lips 14, 15. 17. Further, a notch 18 is provided at the front end of the labyrinth lip 17, and the notch 18 is used to absorb swelling when the labyrinth lip 17 is exposed to foreign matter A outside the machine and swells. The sliding lips 14 , 15 are arranged inside the machine of the labyrinth lip 17 , and the labyrinth lip 17 is arranged outside the machine of the sliding lips 14 , 15 .

[0049] The sealing device 11 is constituted by a metal ring (mounting ring) 12 and a rubber-like elastic body 13 covering (vulcanized and bonded) the metal ring 12 .

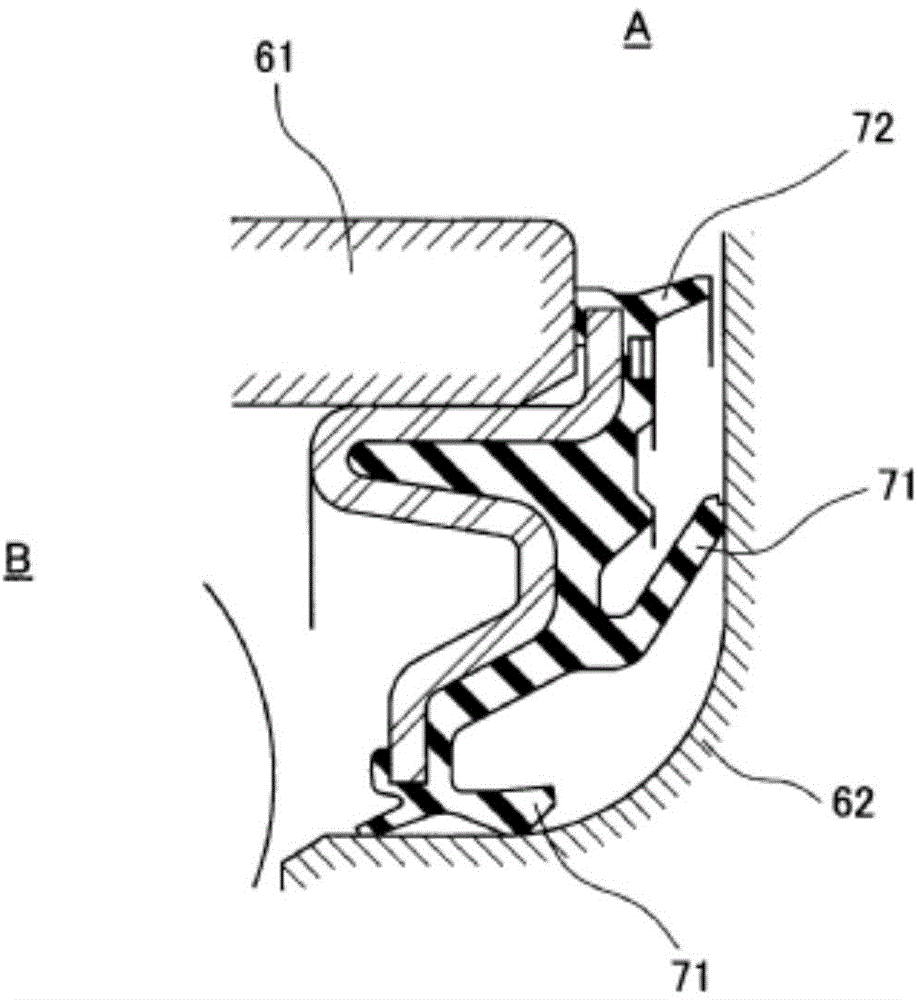

[0050] The ferrule 12 has an outer ring (housing) 61 (see image 3 ) on the inner peripheral surface of the cylindrical portion 12a, on the ...

no. 2 example …

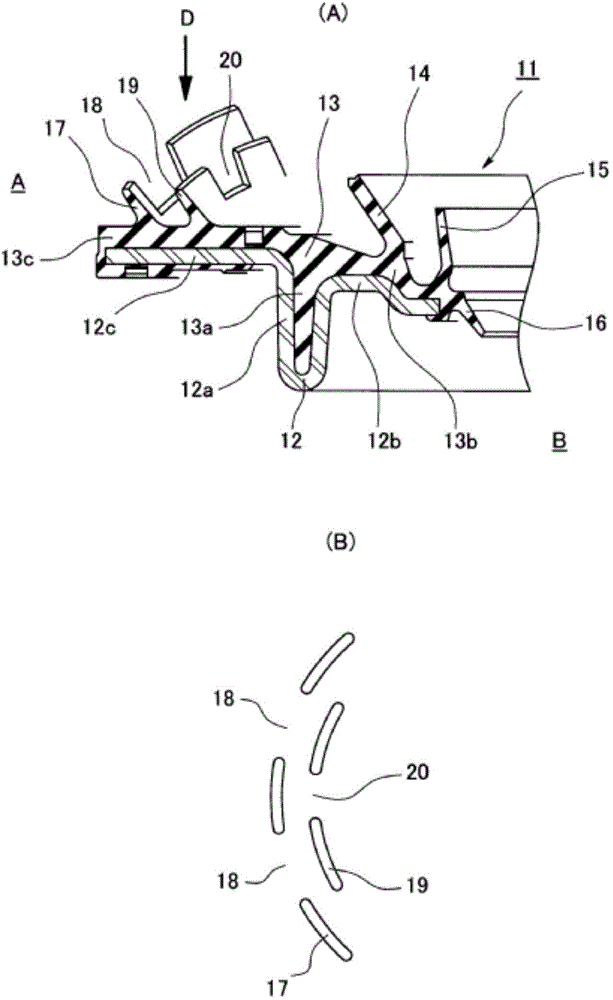

[0055] figure 2 The sealing device 11 shown in is provided with sliding lips 14, 15 for sealing so that foreign matter from the outside A does not enter the inside B of the machine, and a labyrinth lip that makes it difficult for foreign matter from the outside A to reach the sliding lips 14, 15. 17. Further, a notch 18 is provided at the front end of the labyrinth lip 17, and the notch 18 is used to absorb swelling when the labyrinth lip 17 is exposed to foreign matter A outside the machine and swells. also, figure 2 (A) is a sectional view of main parts of the sealing device 11, and also depicts a state (perspective view) overlooking the sliding lips 14 and 15 from obliquely above.

[0056] The sealing device 11 is constituted by a metal ring (mounting ring) 12 and a rubber-like elastic body 13 covering (vulcanized and bonded) the metal ring 12 .

[0057] The ferrule 12 has an outer ring (housing) 61 (see image 3 ) on the inner peripheral surface of the cylindrical port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com