Front bumper and light passenger car with the front bumper

A front bumper, lightweight technology, applied in the direction of bumpers, vehicle parts, vehicle safety arrangements, etc., can solve problems such as unsightly appearance, and achieve the effect of harmonious and unified vehicle body shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are all included in the protection scope of the present invention.

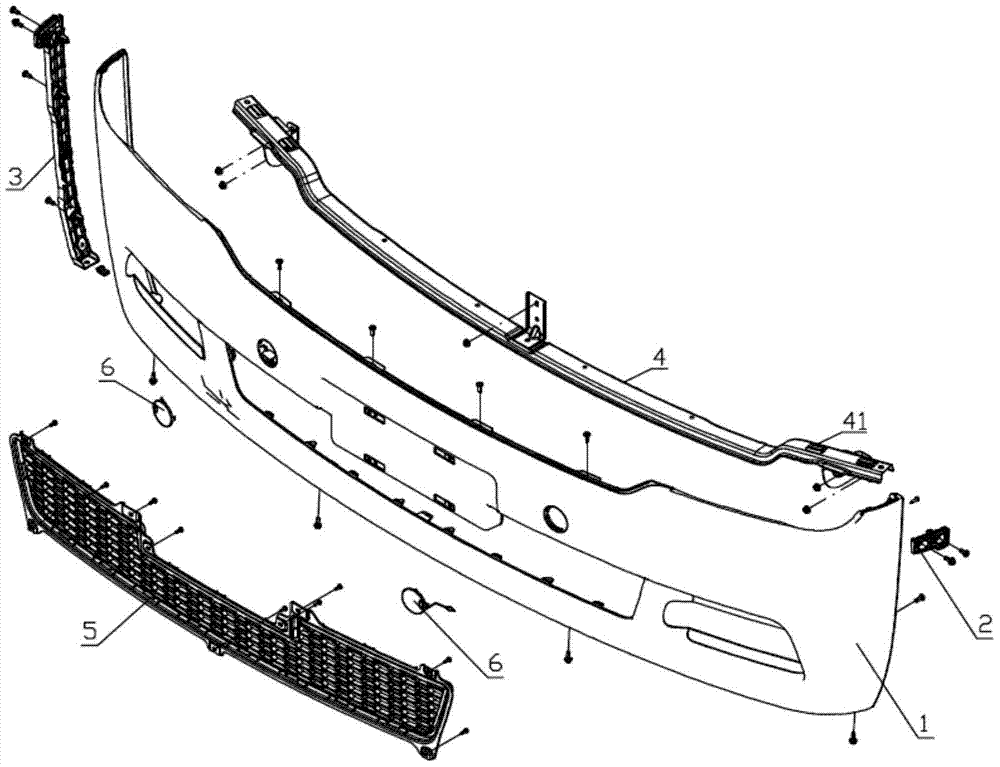

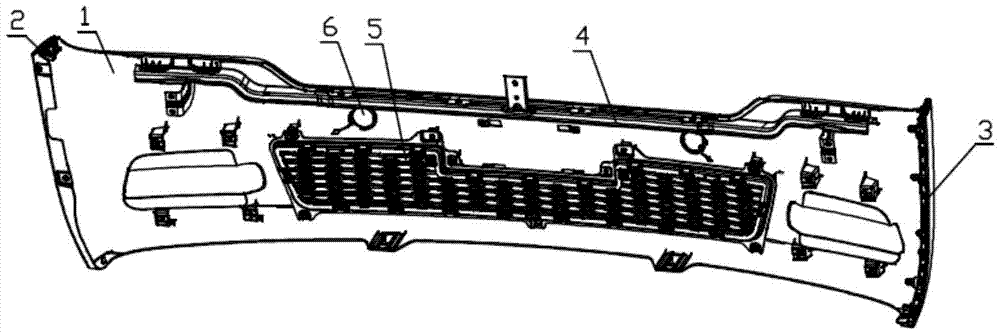

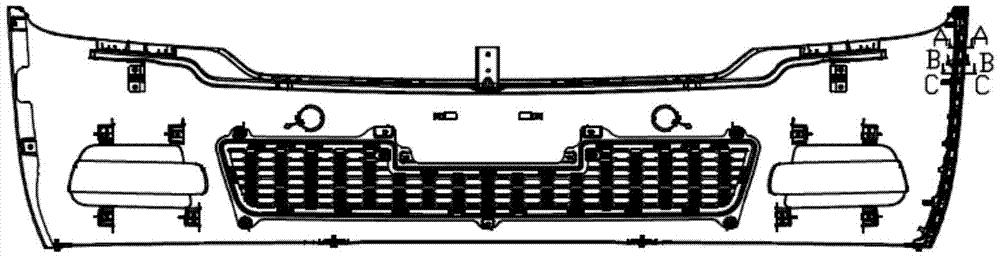

[0040] combine Figure 1 to Figure 3 As shown, a front bumper provided by the present invention includes: a body 1, a left mounting bracket 2, a right mounting bracket 3, a cage assembly 4, a center grid 5, and a coupler blocking cover 6 arranged oppositely. . The shape of the coupler blocking cover 6 is as Figure 20 As shown, it is substantially the same as the prior art, including a circular cover and a tension member pierced on the body 1 .

[0041] The body 1 and the cage assembly 4 are fixed and the cage assembly 4 is located inside the arc of the body 1, specifically, combined with figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com