Adhesive tape and mounting method for image sensor therewith

A technology of image sensor and installation method, applied in the direction of bonding method, film/sheet adhesive, non-polymer adhesive additive, etc., can solve the problem of poor optical inspection, poor identification, and identification of adhesive tape It can protect the surface of the image sensor, improve operability and production efficiency, and ensure the effect of heat resistance and visibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

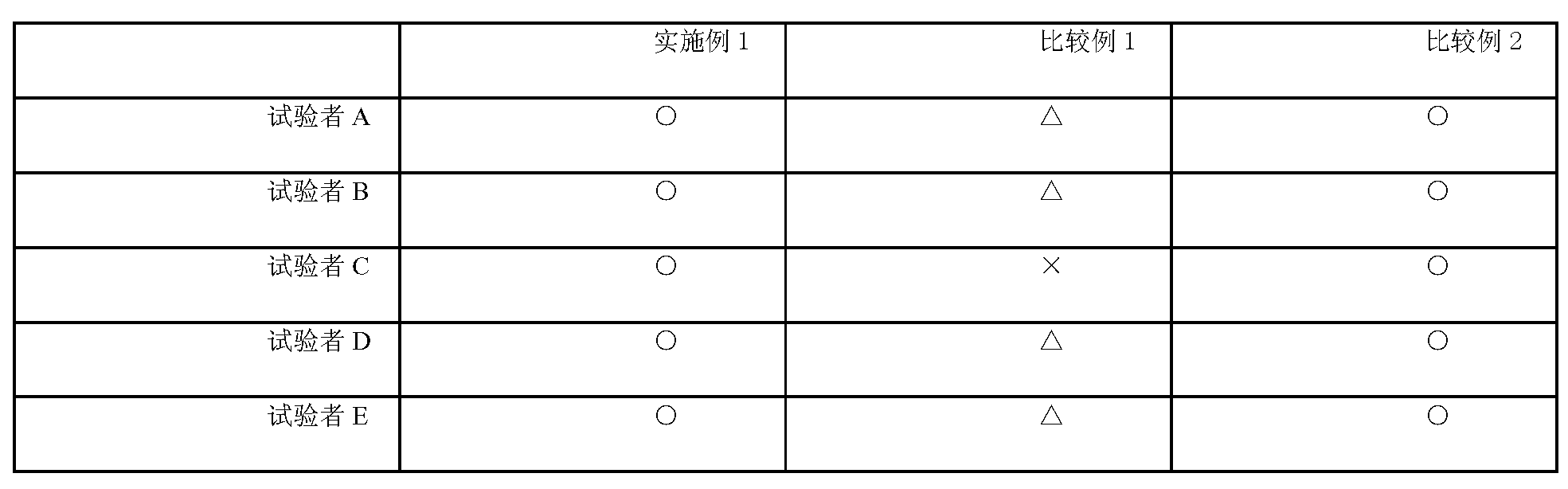

Examples

Embodiment 1

[0066] On a 25μm thick substrate made of polyethylene naphthalate, it is coated on the adhesive composition with 0.5wt% of an antioxidant (manufactured by Chiba Specialty, イルガノツクス) added to the total solid content The solution of the acrylic adhesive was dried to prepare an adhesive tape having an adhesive layer having a thickness of 10 μm. After heating the adhesive tape at 180°C for about 1 hour, the adhesive force measured in accordance with JIS Z0237 was 2.0N / 19mm width, the heat shrinkage rate was 0.15%, and the color of the tape after heating at 180°C for 1 hour was L * a * b * B of the chromaticity diagram * The value is 2.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com