Seal structure using metal gasket

A metal gasket and sealing structure technology, which is applied in the direction of engine sealing, engine sealing device, engine components, etc., can solve the problems of easy corrosion and damaged sealing function, and achieve the effect of corrosion inhibition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Embodiments of the present invention will be described below with reference to the accompanying drawings.

no. 1 example …

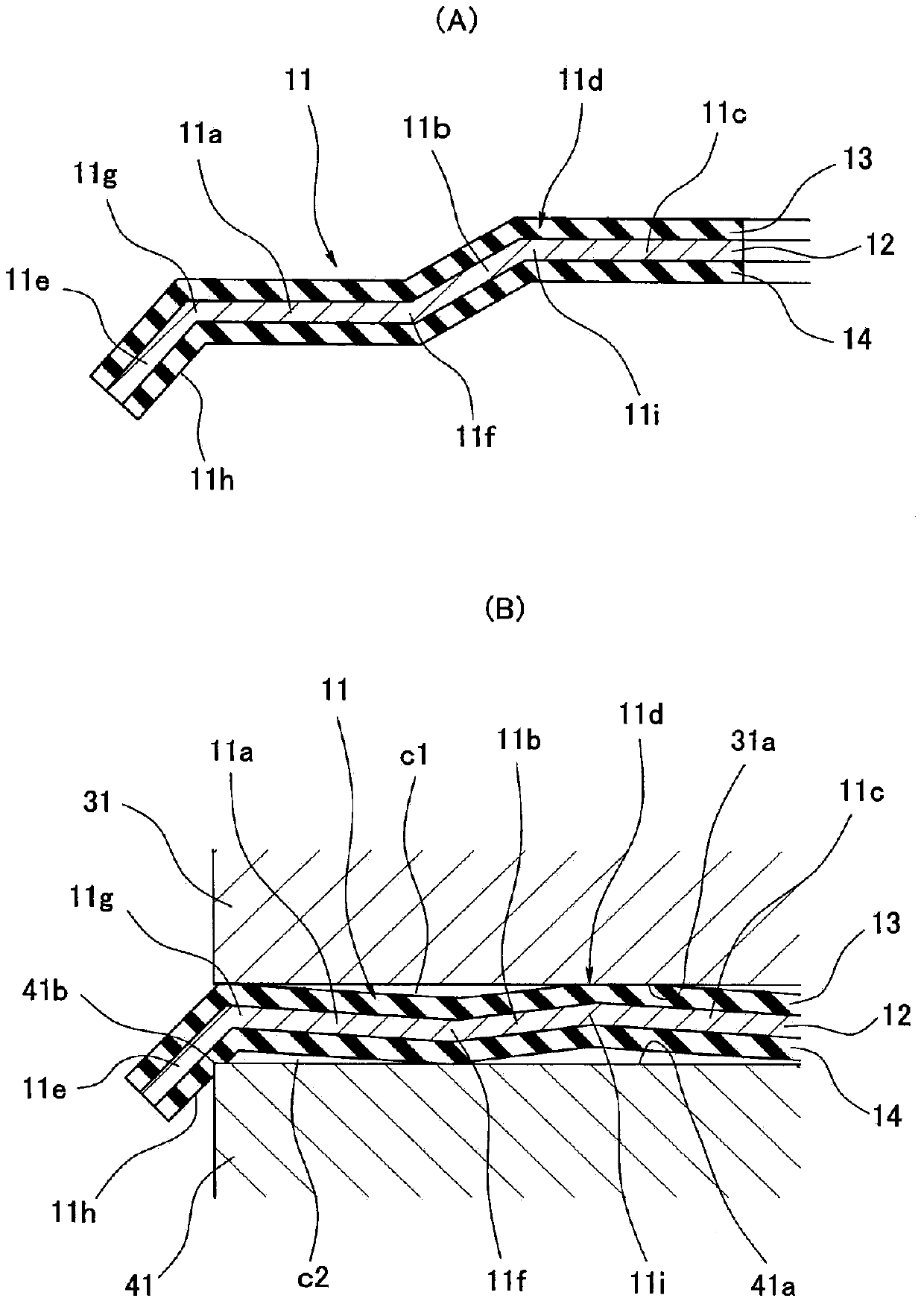

[0056] figure 1 (A) shows a cross-section of a main part of the metal packing 11 used in the sealing structure according to the first embodiment of the present invention, when the metal packing 11 is arranged on a pair of frames (housing or flanges) 31, 41, and if it is clamped (bolt tightened) in the thickness direction of the gasket (up and down in the figure), it becomes figure 1 (B) The fastened state is shown. The left side of each figure is the outer side (outer peripheral side) of the gasket 11 , that is, the sealing fluid side such as salt water, and the right side is the inner side (inner peripheral side) of the gasket 11 . Additionally, if figure 1As shown in (B), a pair of frame bodies 31 and 41 are formed by combining the frame body 31 on the upper side in the figure and the frame body 41 on the other side up and down in the figure. , 41a, install the metal liner 11. Although the frames 31 and 41 are made of aluminum, which is easily corroded by salt water, the...

no. 2 example …

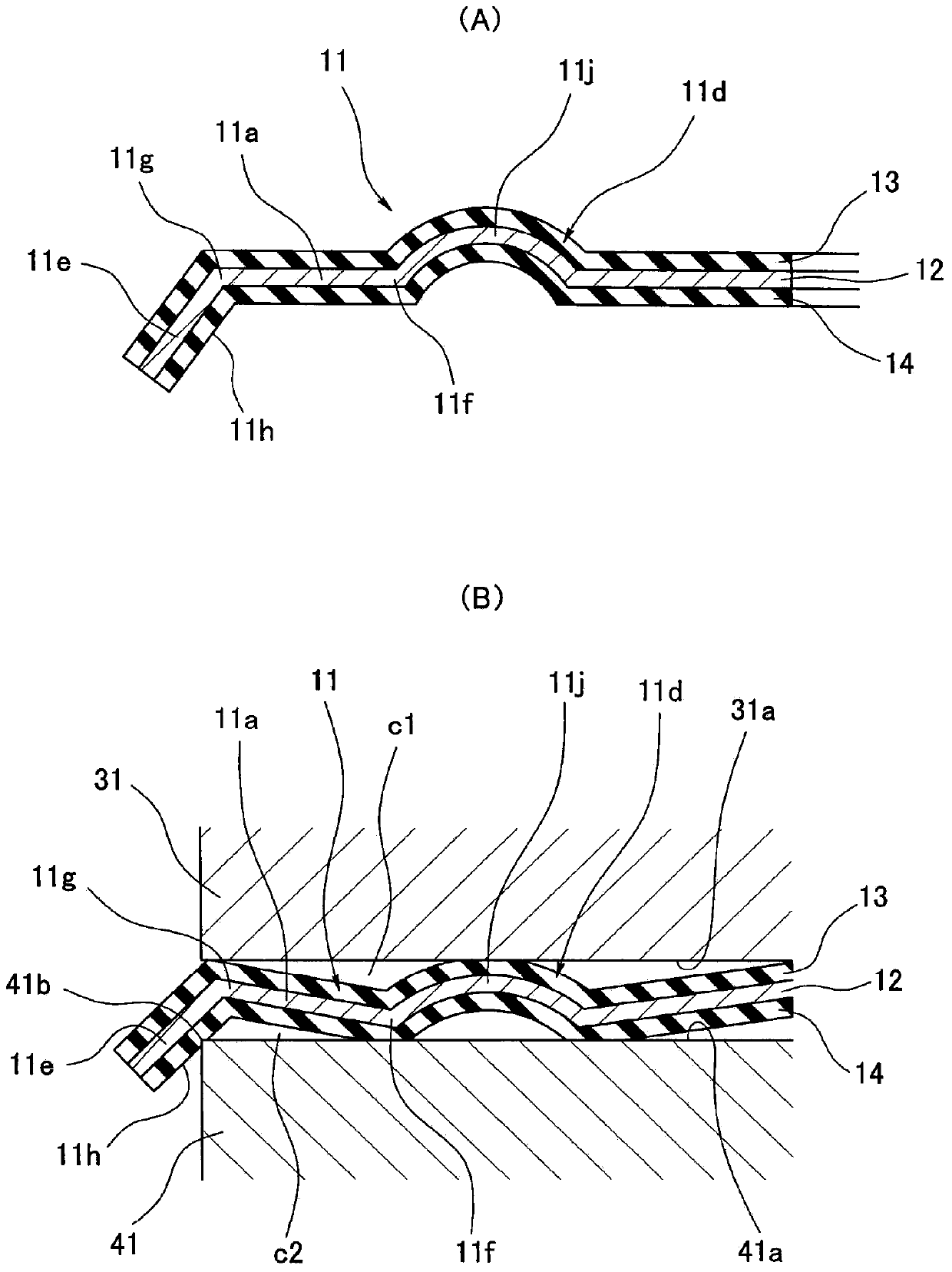

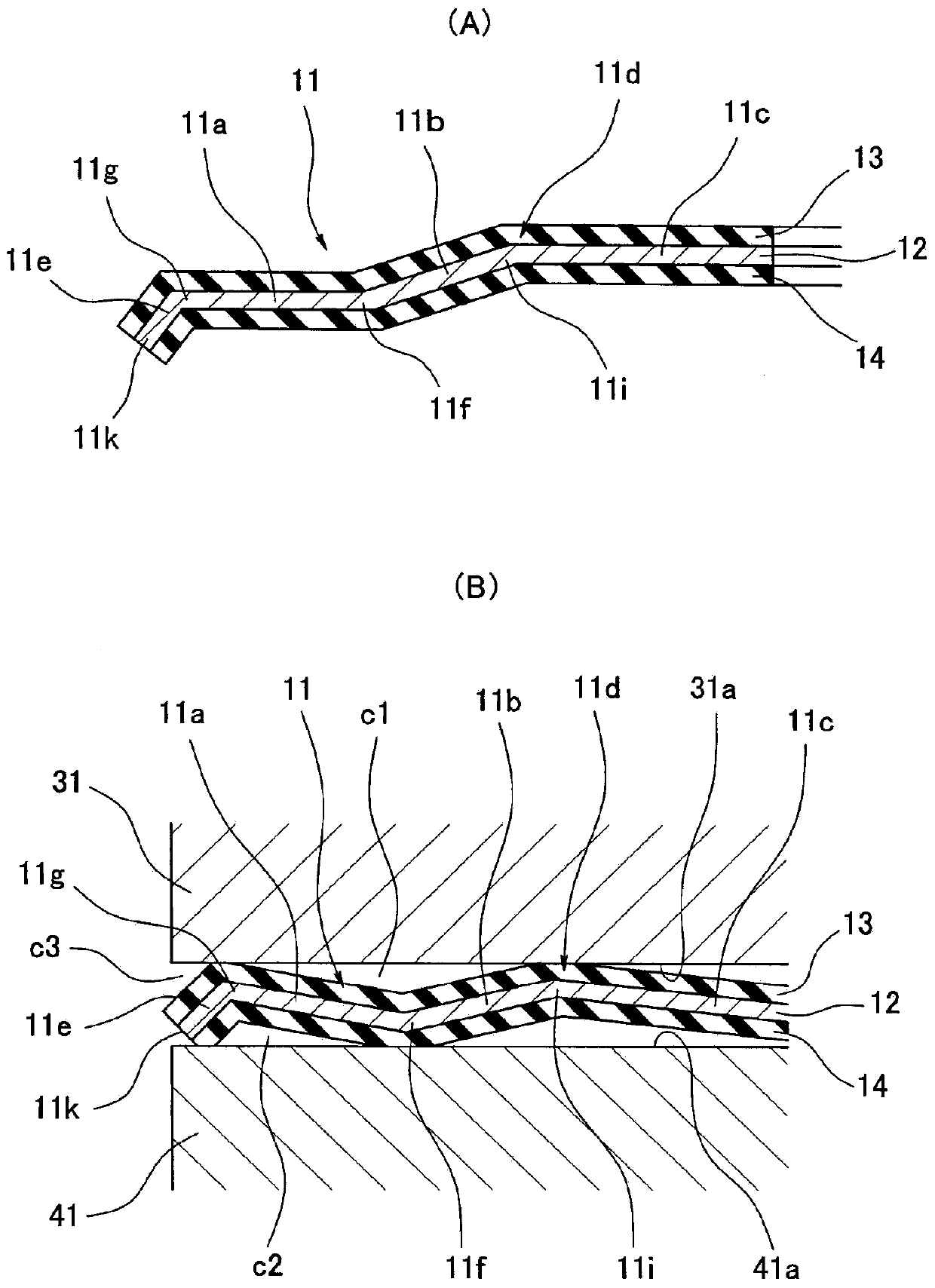

[0063] In the above-mentioned first embodiment, although the flange portion 11d of the metal backing 11 has a semi-flange shape formed by combining the inclined portion 11b and the inner peripheral portion 11c, the shape of the flange portion 11d is not particularly special. It can also be a full-flange shape such as an arc-shaped cross-section or a trapezoidal cross-section. An example of this is described below.

[0064] figure 2 (A) shows a cross section of a main part of the metal packing 11 used in the sealing structure according to the second embodiment of the present invention, when the metal packing 11 is arranged on a pair of frames (cases or flanges) 31 , 41, and if it is clamped (bolt tightened) in the thickness direction of the gasket (up and down in the figure), it becomes figure 2 (B) The fastened state is shown. The left side of each figure is the outer side (outer peripheral side) of the gasket 11 , that is, the sealing fluid side such as salt water, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com