Limiting method for cylinder opening part of cylinder gasket

A cylinder gasket and cylinder port technology, which is applied to the sealing device of the engine, engine components, machine/engine, etc., can solve the problems of cracking, limit failure, low welding efficiency, etc., to ensure the limit function, excellent stability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

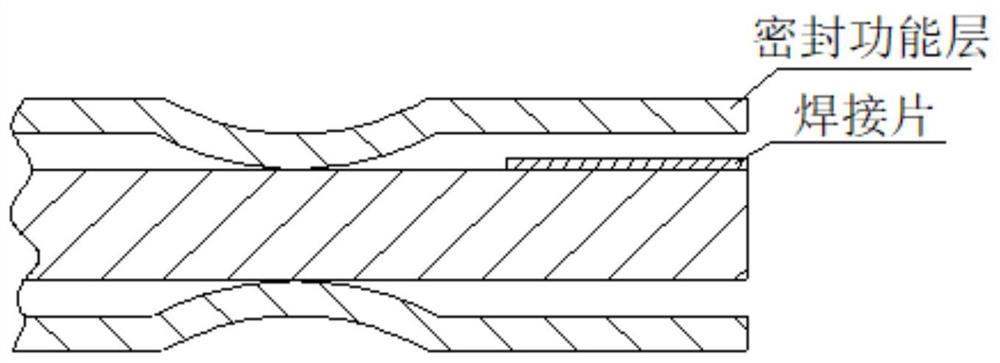

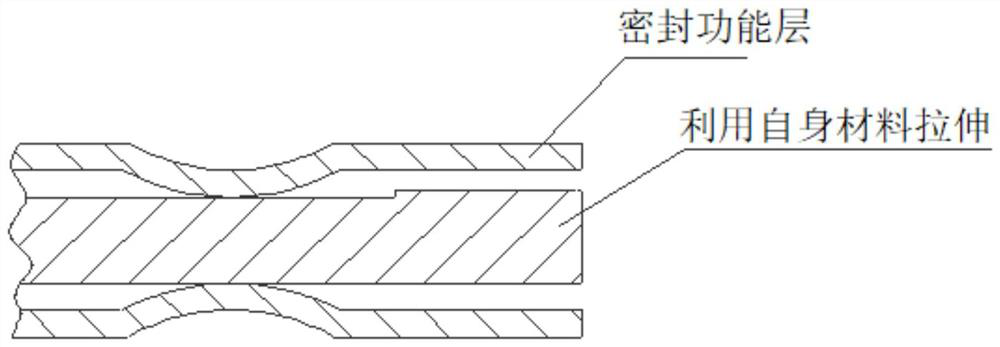

[0040] (1) An adjustment plate is set between the two sealing functional layers, and the volume of the thinned tensile material is reserved at the gap;

[0041] (2) Use a stretching die to thin and stretch the adjustment plate at the gap, the density of the adjustment plate material increases during the stretching process, and the strength of the material itself increases; then the stretched material is crimped and filled into the cylinder Flatten the mouth to form a limiting layer of 0.1mm to 0.15mm, see figure 2 As shown in Fig. 1, the adjustment plate itself can take material to form a limit height difference at the cylinder head of the cylinder gasket.

[0042]The limit method of the cylinder port of the cylinder gasket provided by the embodiment of the present invention adopts thinning and stretching technology, without adding a laser welding machine and additional welding materials, and adding a laser welding machine requires 200,000 to 500,000 yuan, and the additional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com