High-pressure fuel pump

A high-pressure pump and fuel technology, applied in fuel injection pumps, fuel injection devices, liquid fuel engines, etc., to achieve weight saving and manufacturing simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

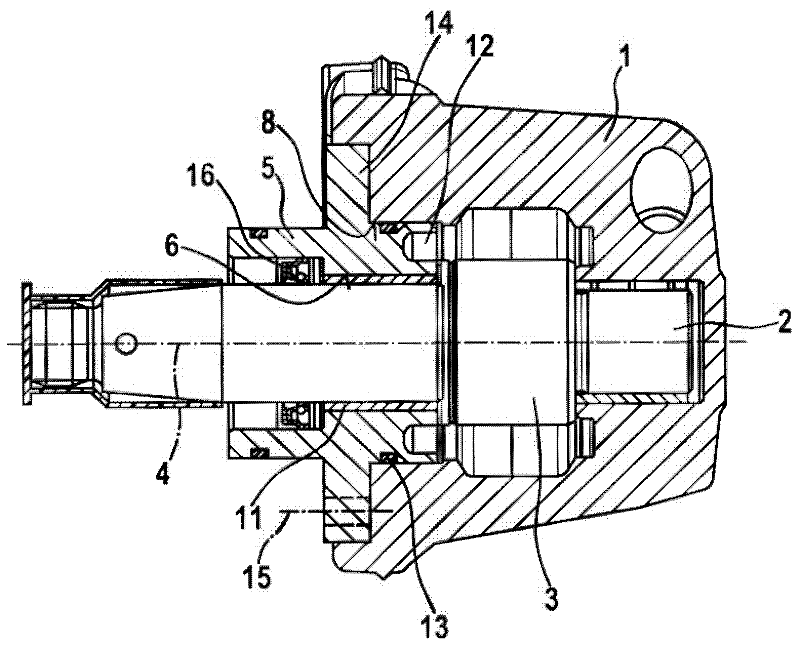

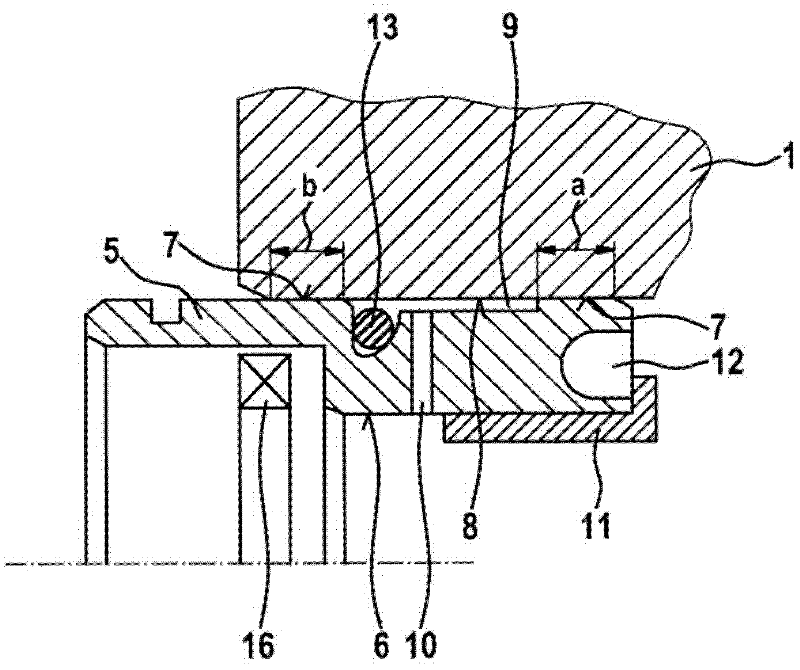

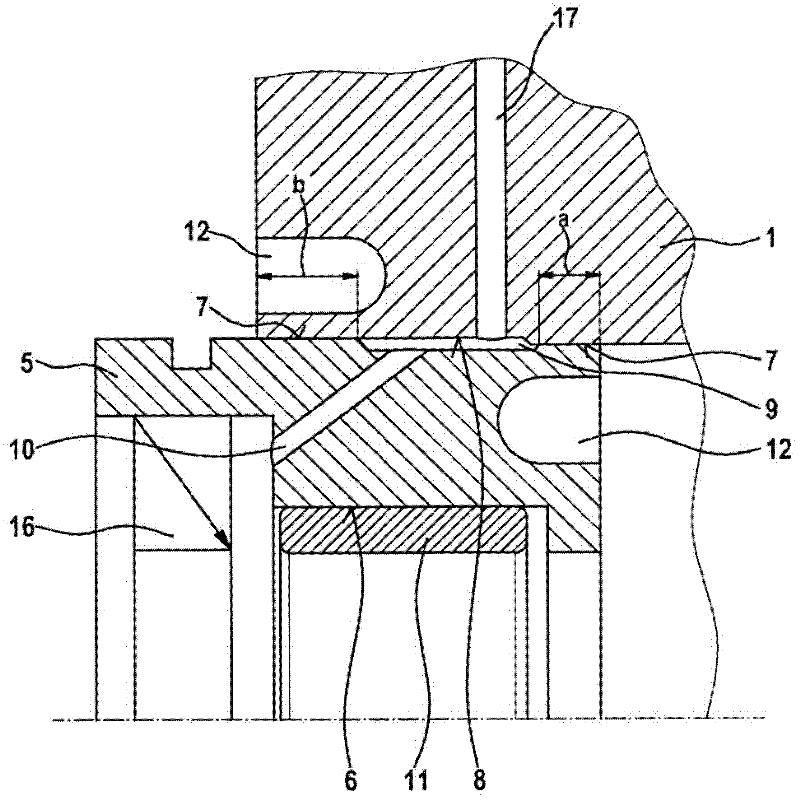

[0021] figure 1 The high-pressure pump shown in and known from the prior art comprises a pump housing 1 in which a formed flange is accommodated for receiving and supporting the drive shaft 2 rotatably about its longitudinal axis 4 Housing part 5 in the form of a disc. In order to form the plain bearing, a plain bearing bushing is inserted in the bearing bore 6 of the housing part 5 . The drive shaft 2 is guided through the plain bearing bushing 11 and its end side is held in the pump housing 1 in a bearing arrangement which is formed as a further plain bearing. The drive shaft 2 has a cam drive 3 for actuating a pump piston (also not shown) of at least one pump element (not shown) for delivering fuel between two slide bearings.

[0022] The housing part 5 is axially abutted against the pump housing 1 by its flange 14 . For fastening, the flange 14 is connected to the pump housing by means of at least one screw 15 . Usually 4 or 6 screws 15 are provided on the flange 14 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com