Novel air-inflation-preventing gas valve

An anti-filling and gas technology, applied in the direction of preventing accidental or unauthorized actions, valve details, valve devices, etc. In order to avoid problems such as untested bottles, gas valves cannot prevent private inflation, valves and liquefied gas cylinders are disassembled privately, etc., to achieve the effect of simple structure, normal function, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

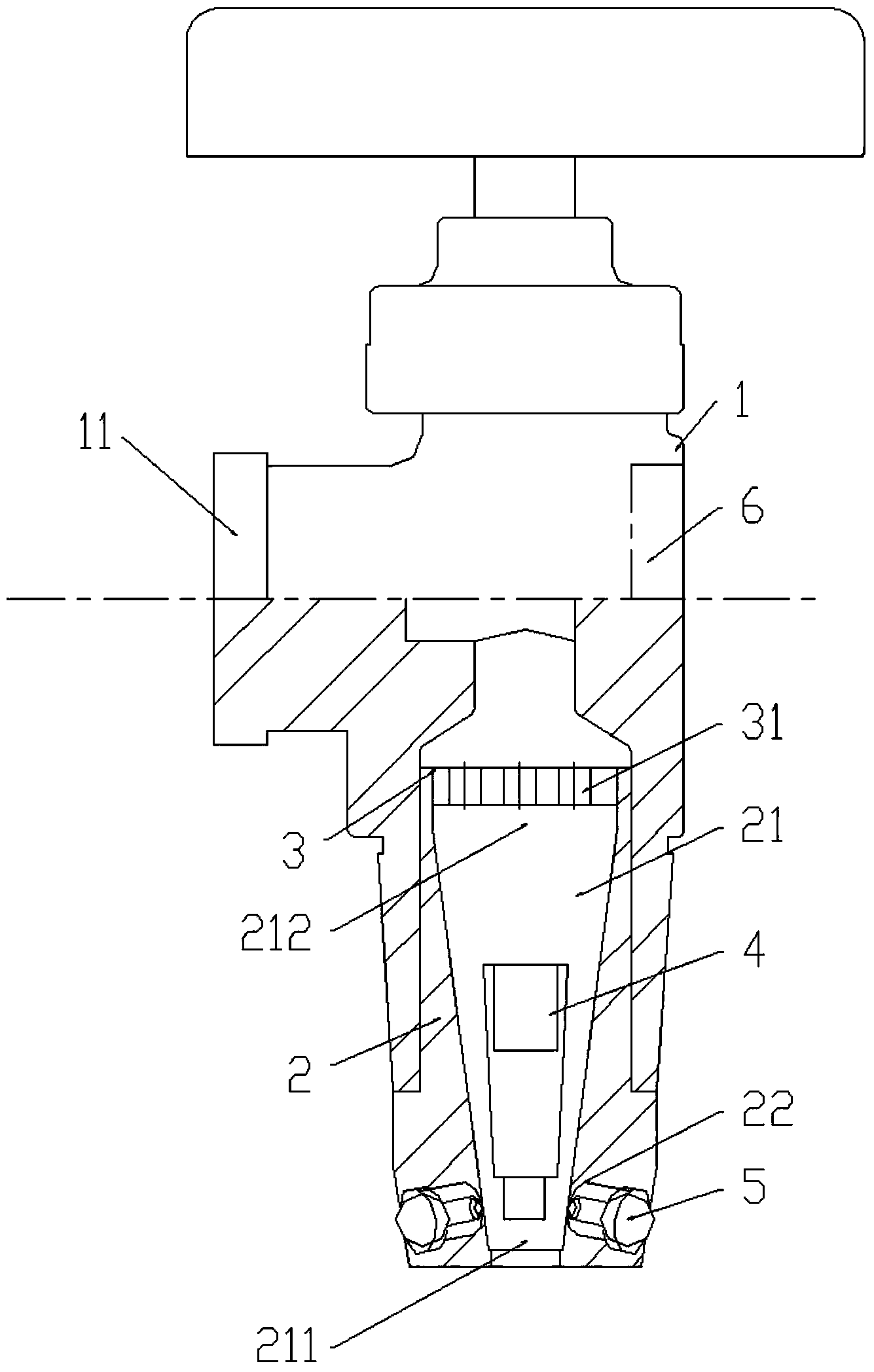

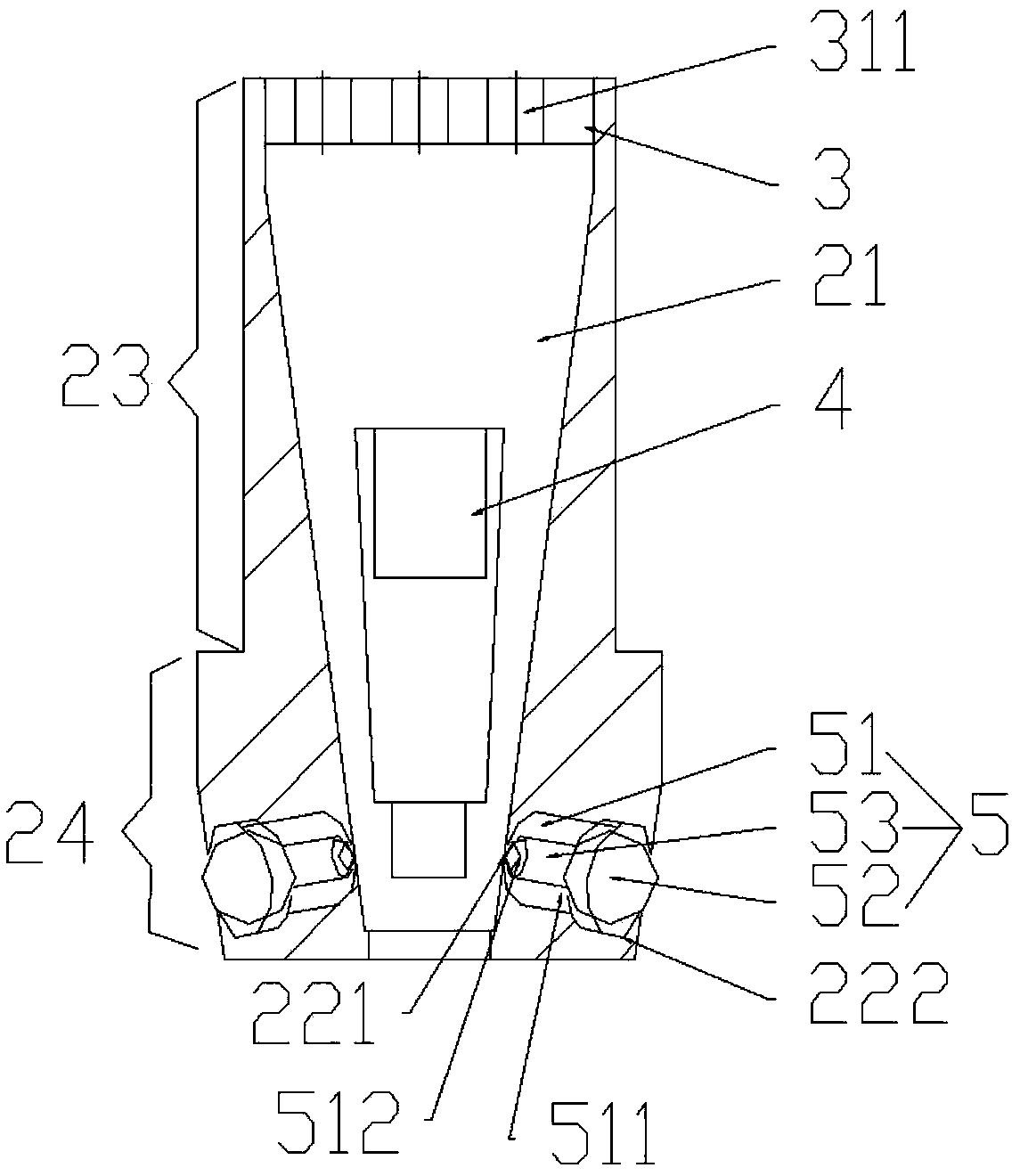

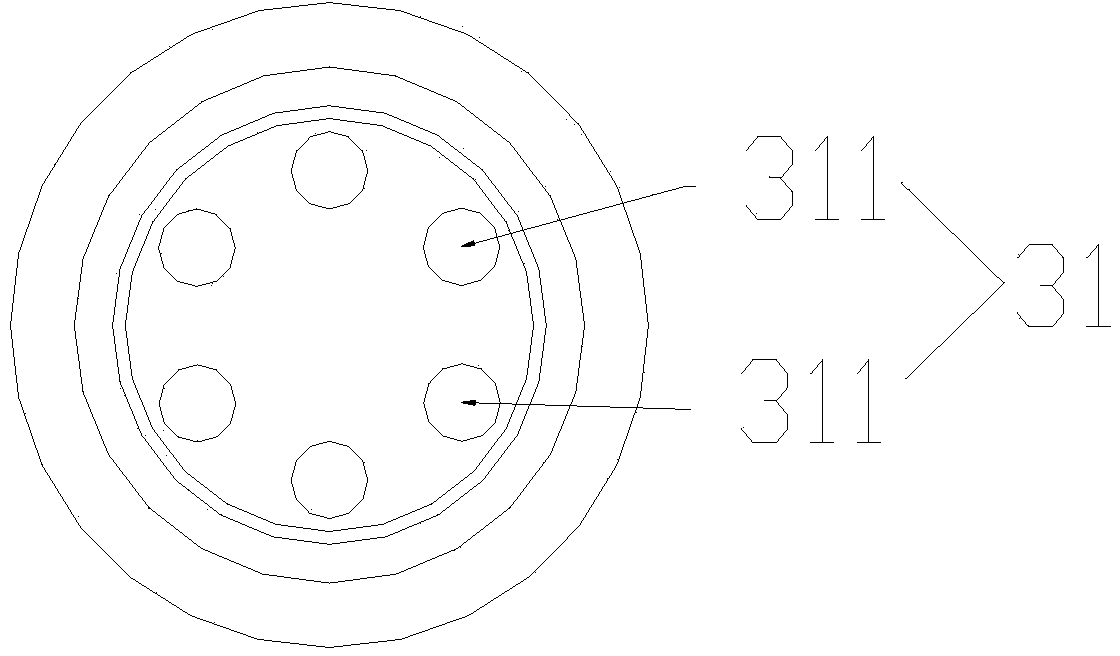

[0029] Such as Figure 1 to Figure 5 The embodiment shown is a new type of anti-filling gas valve, which includes a valve body 1 with an air charging port 11, a valve core 2 that cooperates with the valve body 1 and has openings at both ends; The inflation port 11 is located above the anti-stab component 3, and the anti-stab component 3 is provided with a first diversion hole 31 communicating with the inflation port 11; Hole 21, the second diversion hole 21 is provided under the anti-stab component 3, and the second diversion hole 21 is provided with a closing member 4 inside the second diversion hole 21 to close or unblock the second diversion hole 21.

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com