Sealing ring for sealing aligning roller bearing

A self-aligning roller bearing and sealing ring technology, applied in the field of bearing sealing, can solve the problems of pressure difference between the inside and outside of the bearing, the bearing is stuck, and the bearing starting torque is large, and the effect of ensuring the sealing performance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

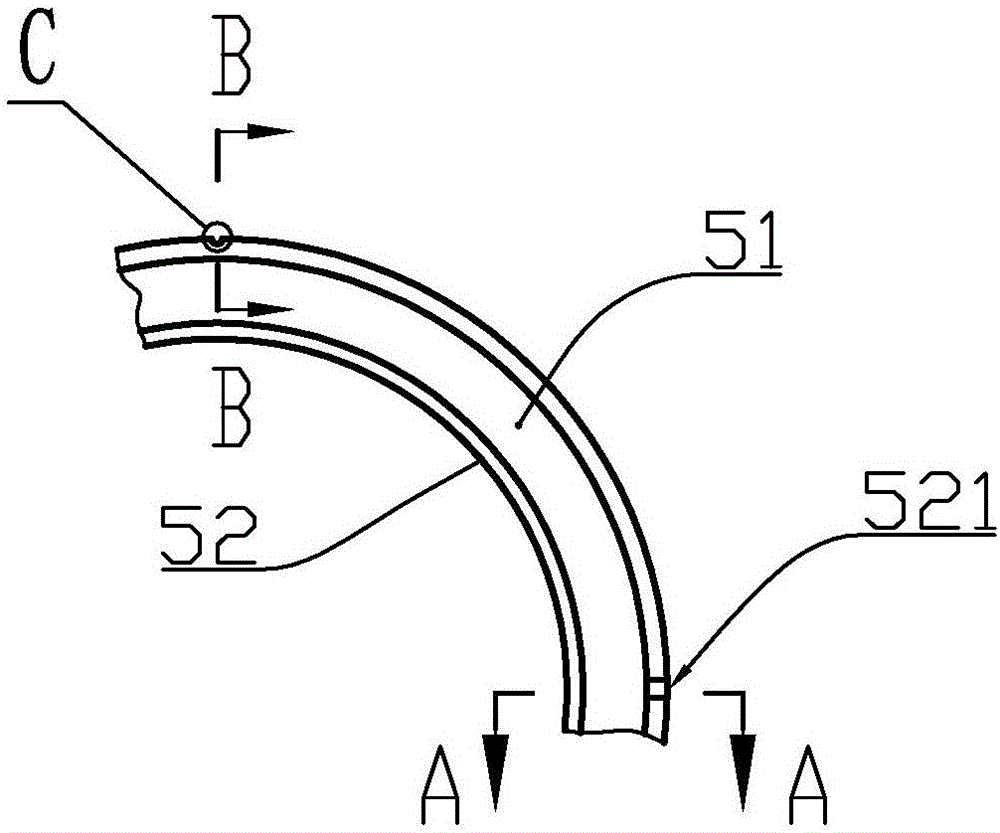

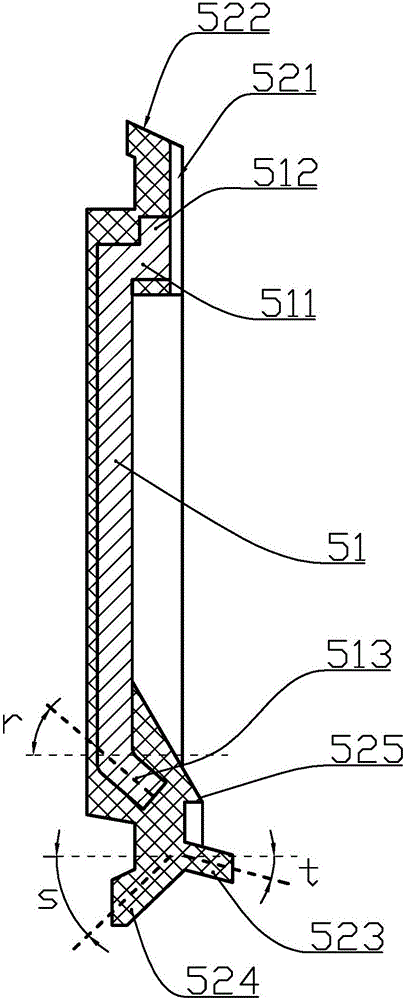

[0019] according to Figure 1 to Figure 5 As shown, the sealing ring of a sealed spherical roller bearing described in this embodiment includes a rubber ring 52 and a steel ring 51 embedded in the rubber ring; Vertical first bending portion 511, the outer end of the first bending portion is formed with a second bending portion 512 parallel to the end surface of the steel ring, and the inner circumference of the steel ring is formed to bend toward the inner side of the sealing ring The third bending portion 513, the angle r formed between the third bending portion and the axial direction of the steel coil is 49°.

[0020] The outer circumference of the rubber ring is a tapered surface 522 with narrow inside and wide outside. The outer circumference of the rubber ring is formed with a gap 526 in the axial direction, and the inner wall of the rubber ring is formed with a vent hole 521 at a position different from the gap in the circumferential direction. .

[0021] The inner pe...

Embodiment 2

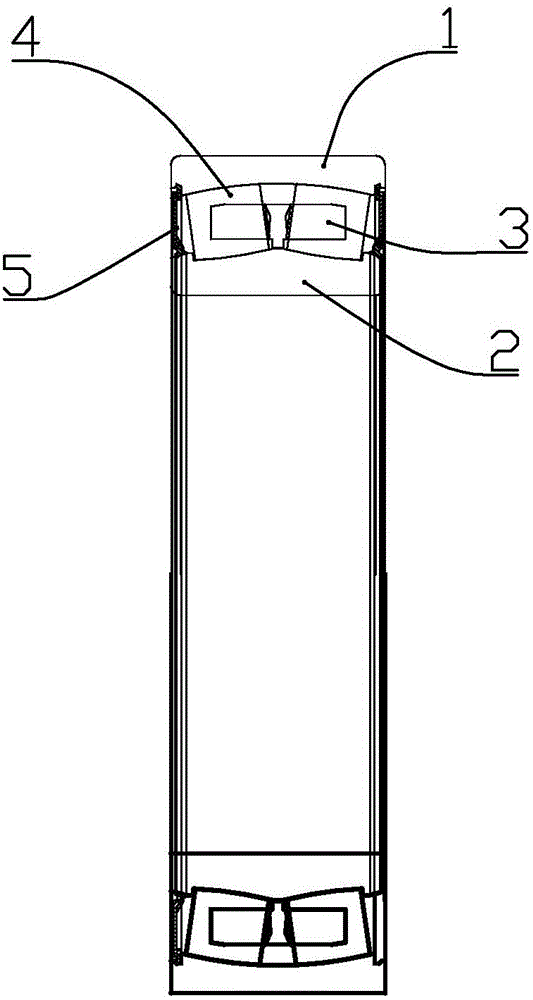

[0028] This embodiment is a sealed spherical roller bearing, which includes an outer ring 1 and an inner ring 2, and two sets of rollers 4 installed between the outer ring and the inner ring to position the rollers for holding Frame 3, and the above-mentioned sealing ring 5 fixedly connected to both sides of the outer ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com