Clamping controllable disc-shaped rotary type inertia piezoelectric actuator and actuation method

A piezoelectric actuator, rotary technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of reducing the efficiency of inertial actuator use, structure Complex, low strength and other problems, to achieve the effect of reasonable utilization of internal space, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

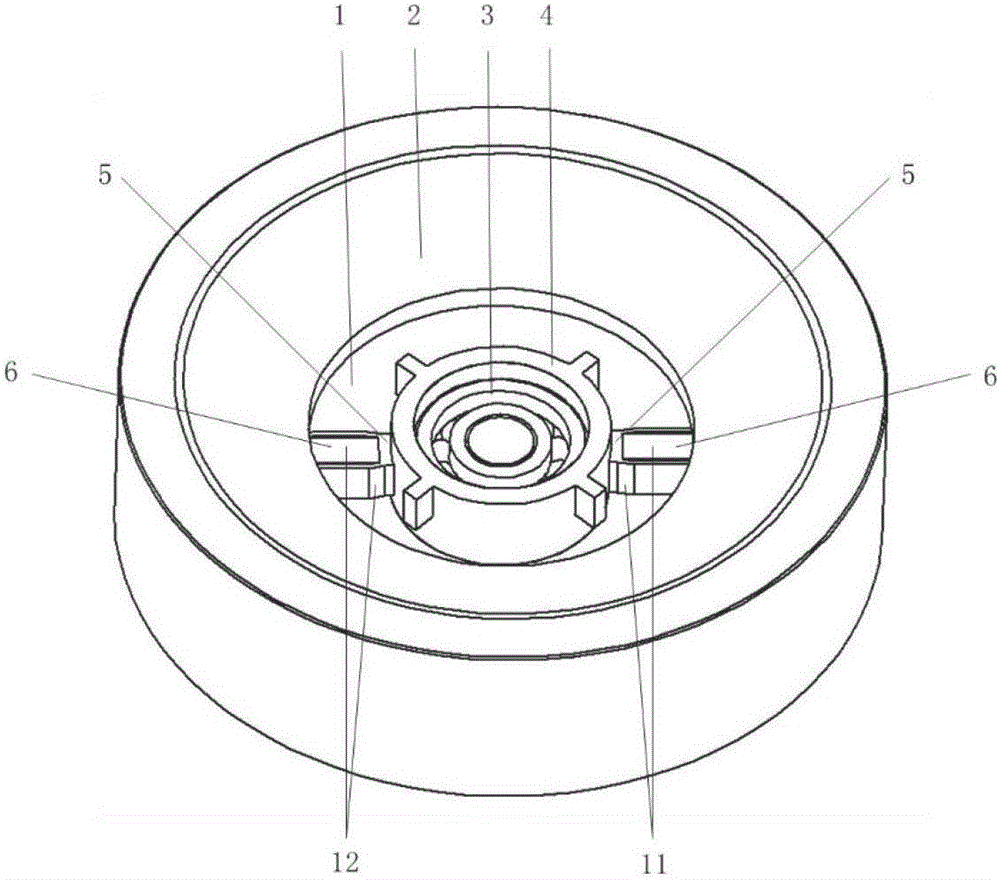

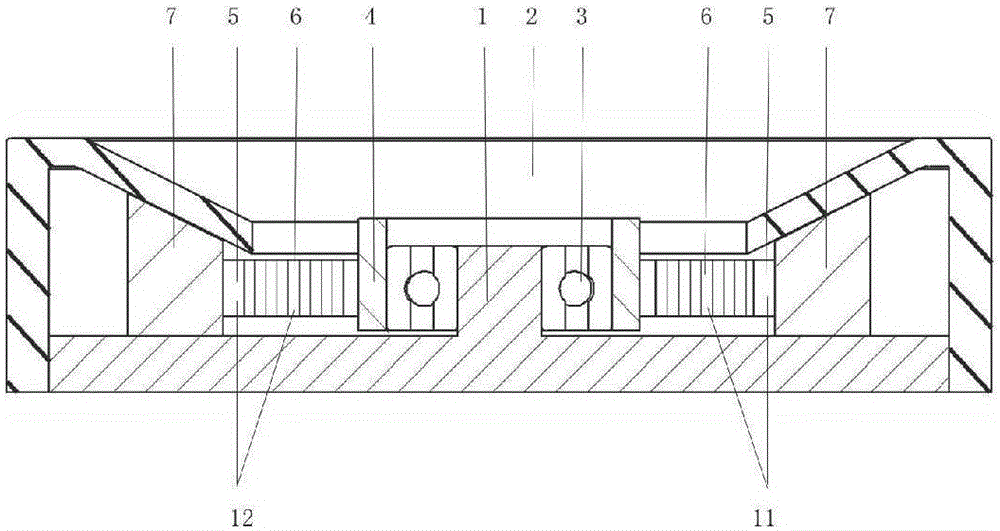

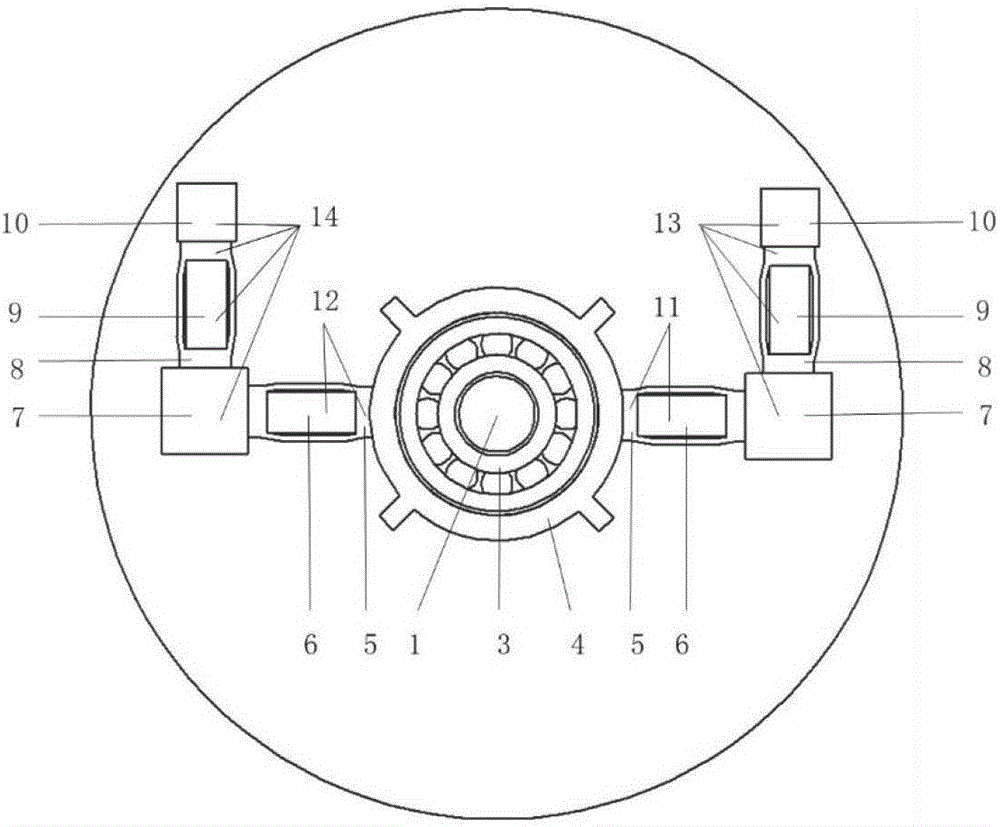

[0020] Such as Figure 1 to Figure 4 As shown, the clamp controllable disc-shaped rotary inertial piezoelectric actuator of the present invention includes a base 1, a clamp housing 2, a bearing 3, an output ring 4, a clockwise clamp mechanism 11, and a counterclockwise clamp mechanism 12 1. The clockwise driving mechanism 13 and the counterclockwise driving mechanism 14, the whole actuator structure is symmetrical; wherein the clamping shell 2 is obtained by turning an "M" shaped section with a certain thickness and cutting the central part to form a round hole, and the clamping shell 2 The internal thread is connected with the external thread on the circumferential side of the base 1; the clockwise clamping mechanism 11 and the counterclockwise clamping mechanism 12 both include a clamping rhombic ring 5 and a clamping piezoelectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com