Main shaft neck part oil return mechanism of driving shaft of scroll compressor

A scroll compressor and compression mechanism technology, applied in the field of scroll compressors, can solve the problems of rising manufacturing costs, difficult operations, and many processing procedures, and achieve the effects of reducing processing costs, avoiding rising manufacturing costs, and reducing assembly requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

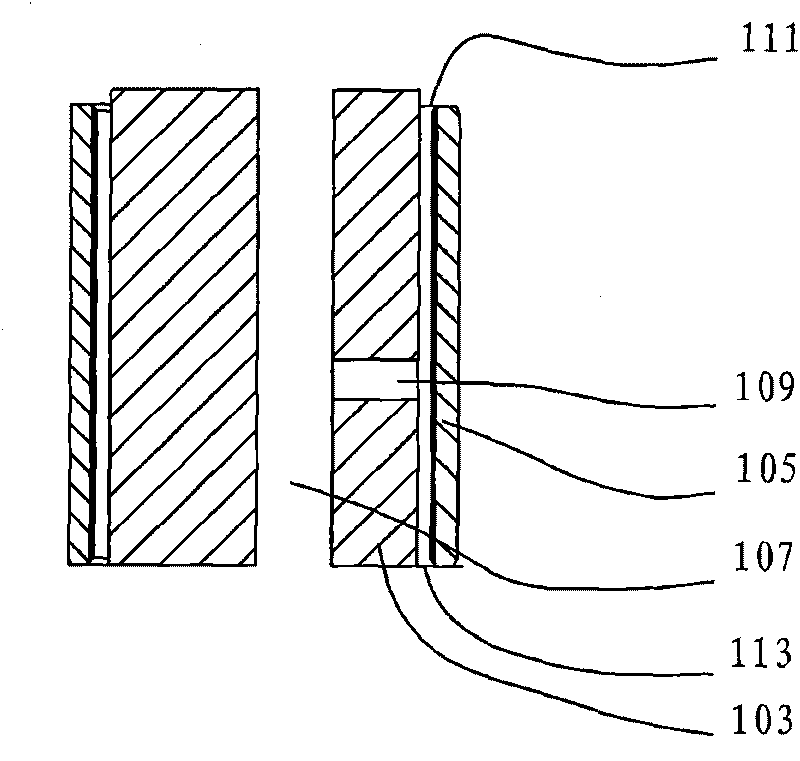

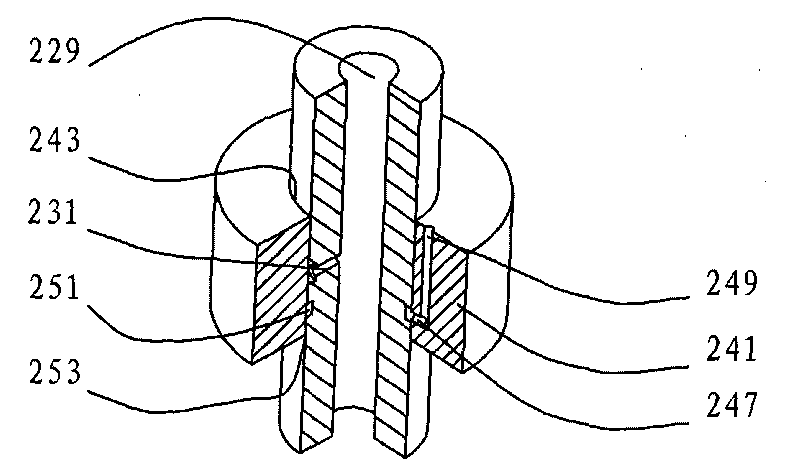

[0024] see Figure 4 , the scroll compressor, the compression mechanism part 2 and the motor part 7 are connected through the drive shaft 5 , that is, the crankshaft, and accommodated in the airtight container 1 . The compression mechanism part 2 is composed of a fixed scroll 4 , a movable scroll 3 , a frame 6 , a drive shaft 5 and an Oldham ring 8 as main components.

[0025] The fixed scroll 4 has an end plate 4b and a spiral fixed scroll 4a standing upright on the end plate 4b. The fixed scroll 4 is fastened on the upper side of the frame 6 by screws. The periphery of the frame 6 is fixed on the airtight container 1, and at the bottom of the airtight container 1, there is a main bearing 16 supporting the rotation of the drive shaft 5.

[0026] The airtight container 1 includes an upper casing 20 , a main casing 21 and a lower casing 22 connected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com