Prismatic reflection type calibrator and calibration method thereof

A reflective and calibrator technology, applied in instruments, measuring devices, optical devices, etc., can solve the problem of inability to train on-site inspection and measurement work, and achieve the effects of simplified processing technology, simple structure, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

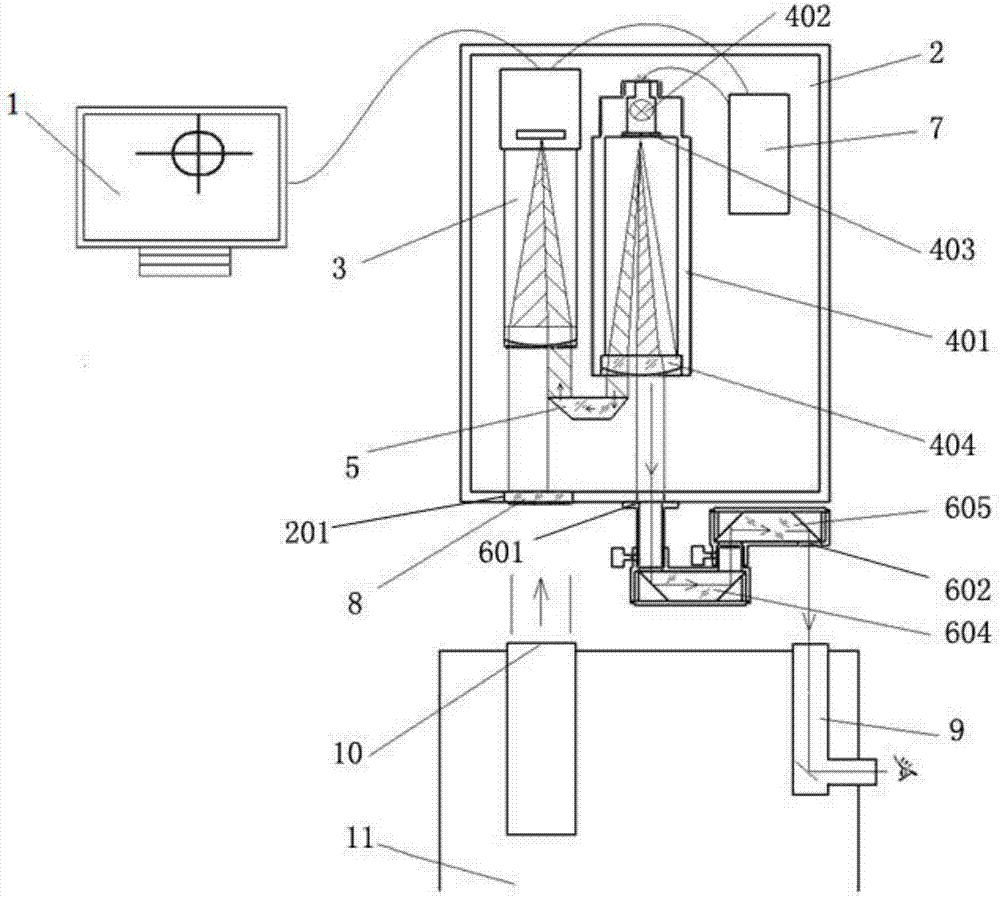

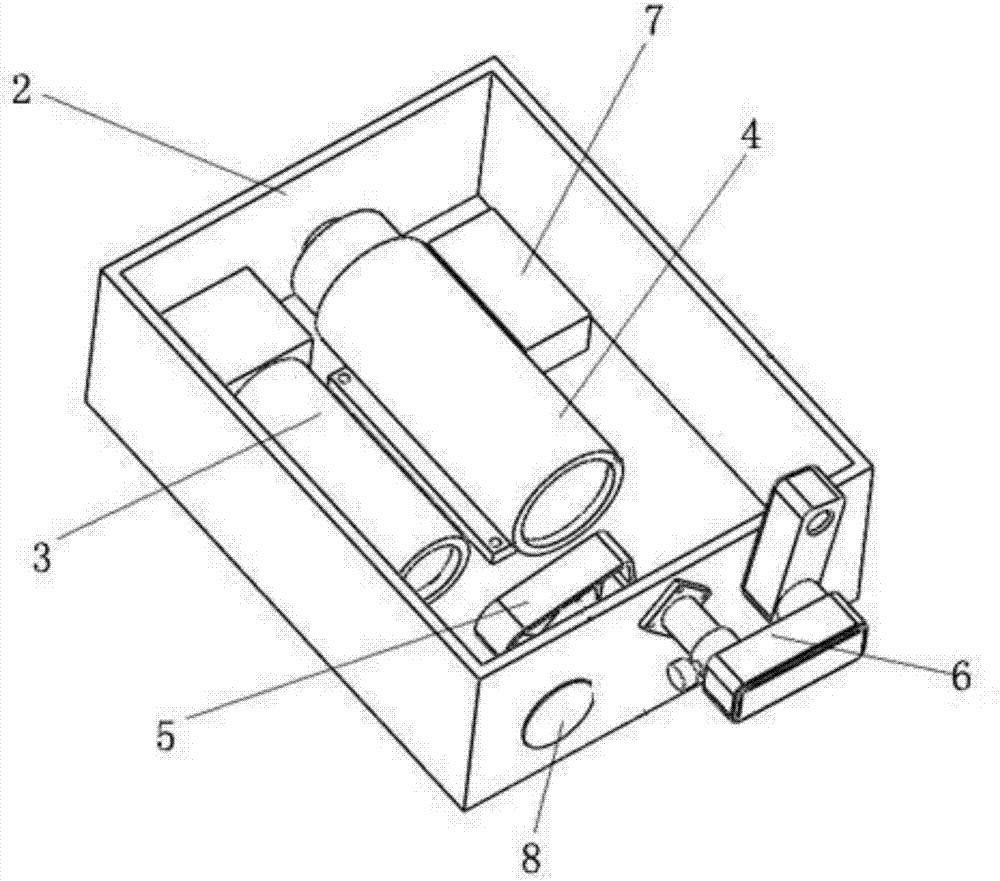

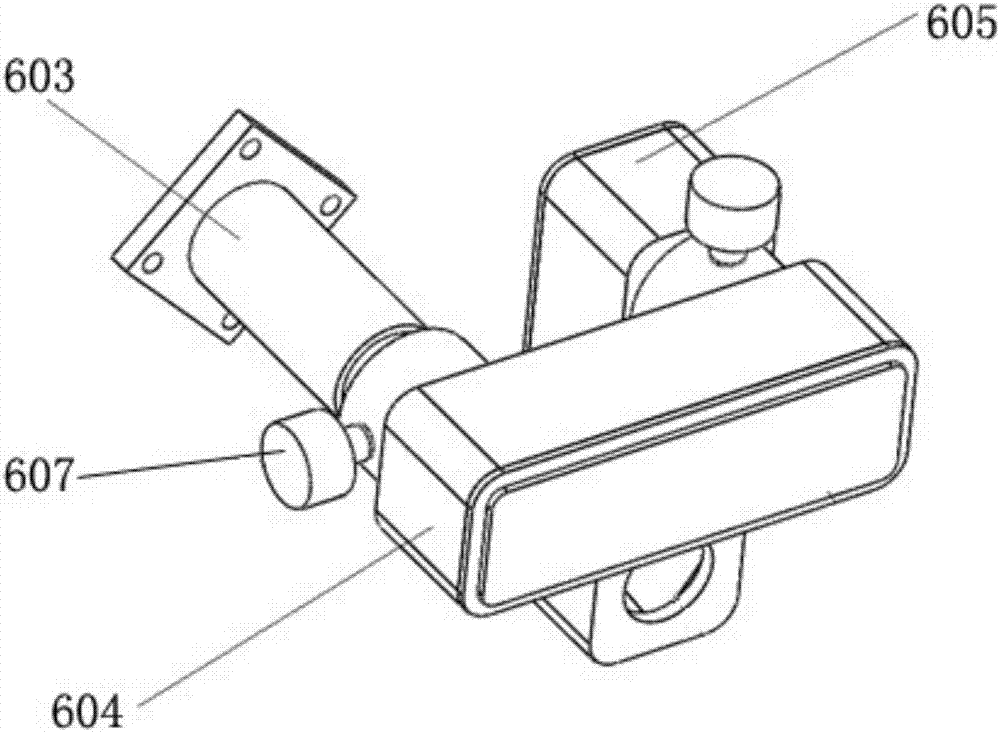

[0038] A prism reflective collimator, the structure is as follows Figure 1~7 shown.

[0039] refer to figure 1 , 2 , the calibrator includes a display 1, and also includes a box 2, in which a camera 3 and a collimator 4 are arranged side by side, and a power module 7 is also arranged. The display 1 is connected to the camera 3, and the camera 3 and the collimator 4 are respectively connected to the power module 7.

[0040] The parallel lamp tube includes a lamp tube body 401, a reticle lighting lamp 402, a reticle 403 and a collimating lens 404. The collimator lens 404 is located at the bottom nozzle of the lamp tube body 401 directly below. The collimator 4 can produce a bright reticle for aiming at a target under a dark background.

[0041] The box body 2 is also provided with a first three-pronged prism 5 . The two ends of the first three-vertical prism 5 are respectively located directly below the adjacent parts of the camera 3 and the collimator 4, one end can rece...

Embodiment 2

[0054] Under the special requirement of the shape of the laser transmitter, the side of the calibrator described in Embodiment 1 can be turned downwards to work in a vertical state.

Embodiment 3

[0056] The collimator described in Embodiment 1 works in combination with the three-dimensional adjustment platform, which facilitates the placement and alignment of the measured laser transmitter 11 and improves work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com