Five-stage microstrip line bridge

A technology of stripline bridge and microstrip line, which is applied in the direction of circuits, electrical components, connecting devices, etc., can solve the problems of high precision processing requirements, difficulties in bridge couplers, and difficulty in ensuring the rigidity of striplines, so as to reduce processing requirements The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

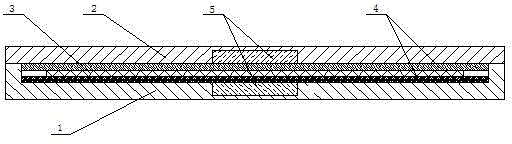

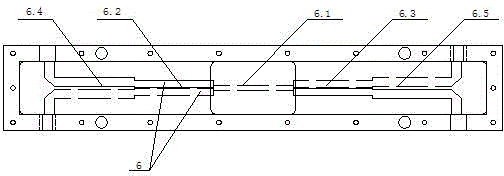

[0015] refer to Figure 1-2 , a five-level microstrip line bridge, which is composed of a cavity 1, a cover plate 2, a circuit board 3, a dielectric plate 4, and an additional dielectric plate 5. The cover plate 2 is installed above the cavity 1, and the cavity 1 is set There is a circuit board 3, the upper and lower sides of the circuit board 3 are respectively provided with a microstrip line 6, the four ends of the microstrip line 6 can be connected to the outside through the cavity 1, and the upper and lower sides of the circuit board 3 are respectively provided with a dielectric board 4, Additional dielectric plates 5 are provided on the outside of the dielectric plate 4, and the microstrip lines 6 are composed of a first-level coupling area 6.1, a second-level coupling area 6.2, a third-level coupling area 6.3, a fourth-level coupling area 6.4, and a fifth-level coupling area. 6.5 composition, viewed from a top view, the first-level coupling regions 6.1 of the two microst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com