Novel coupler

A coupler and a new type of technology, applied in the field of couplers, can solve the problems of high machining accuracy, high assembly requirements, and high production costs, and achieve the effects of reducing the machining accuracy, small changes in standing waves, and small fluctuation ranges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

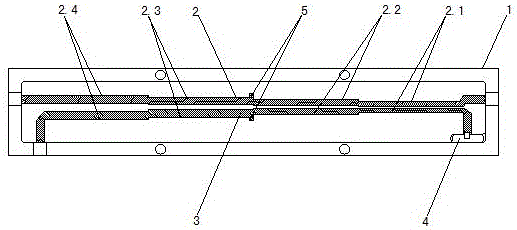

[0011] refer to figure 1 , a new type of coupler, which is composed of a housing 1, a coupling straight rod 2, a coupling curved rod 3, a resistor 4, and a debugging block 5. The coupling straight rod 2, the coupling bending rod 3 are arranged in the cavity of the housing 1, and the coupling Both ends of the straight rod 2 can be connected to the outside through the casing 1, one end of the coupling curved rod 3 can be connected to the outside through the casing 1, and the other end can be connected to the resistor 4. The coupling straight rod 2 and the coupling curved rod 3 are respectively Set a debug block 5 each.

[0012] The straight coupling rod 2 and the curved coupling rod 3 are respectively composed of a first-level coupling area 2.1, a second-level coupling area 2.2, a third-level coupling area 2.3, and a fourth-level coupling area 2.4.

[0013] The debugging block 5 is respectively arranged at the front end of the third-level coupling area 2.3 of the coupling strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com