Compression type packer

A technology of compression packer and seat seal, which is applied in the field of isolation devices for sealing off various oil layers or tubing and casing of oil and gas wells. Sensitive action, convenient processing, and the effect of reducing construction accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

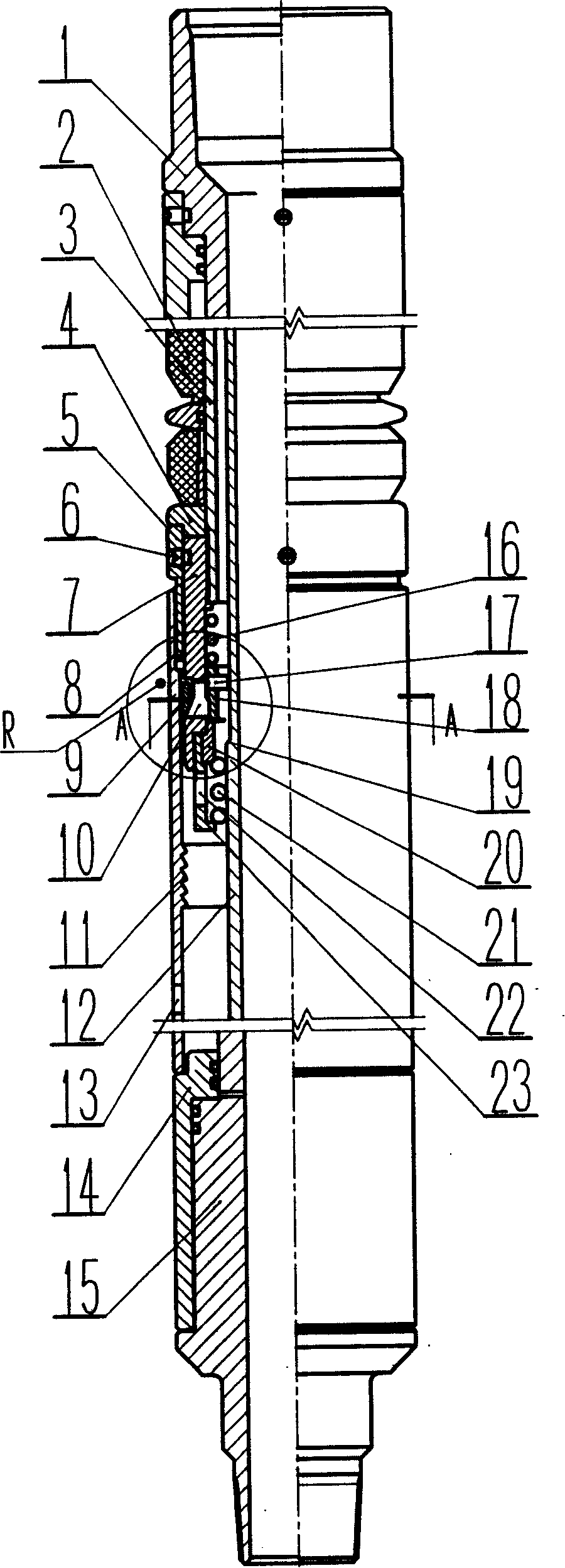

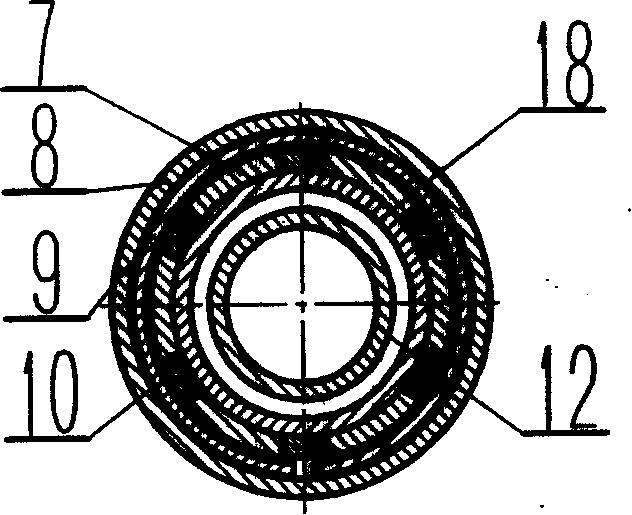

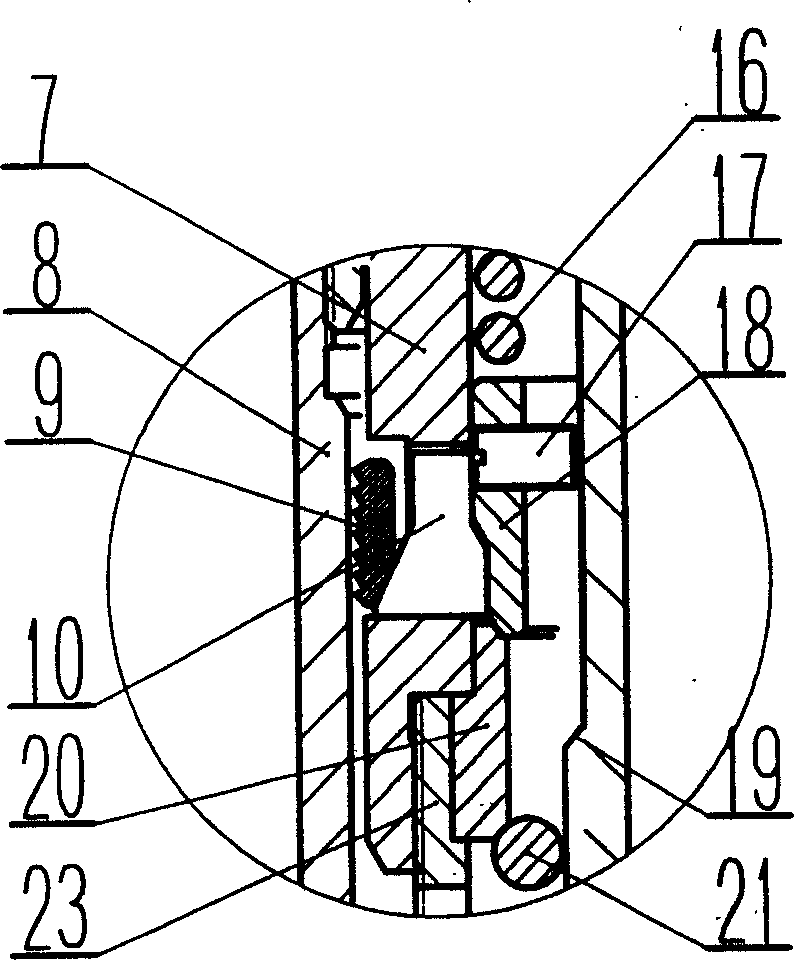

[0025] like Figures 1 to 3 As shown, the compression packer includes an upper joint 1 , a well flushing mechanism, a rubber cartridge sealing mechanism, a seat sealing mechanism and a lower joint 15 . The seat seal mechanism includes a lock sleeve 8, a lock ring 9, a wedge-shaped lock block 10, a lock ring seat 7, and a central tube 12. The outer cylindrical surface of the lower end of the lock ring seat 7 is provided with a ring groove, and the lock ring 9 is installed in the ring slot. The annular groove is provided with several waist holes communicating with the inner side, each waist hole is equipped with a lock block 10, the lock ring is 9 split rings, and the outer peripheral surface of the lock ring 9 is provided with one-way locking annular teeth, The lock sleeve 8 is provided with an annular tooth 11 that cooperates with the annular teeth of the lock ring 9, the lower end of the lock ring 9 is provided with an inner conical surface at the contact portion with the low...

Embodiment 2

[0031] Another solution of the present invention is as Figures 6 to 8 As shown, the same parts as those in Embodiment 1 will not be described here again. There is an annular boss 28 on the central tube 12 that matches the inner wall of the lock block 10 . The lower end of the boss 28 is provided with two upper and lower steps 25 and 26 that cooperate with the step 24 at the middle part of the inner side of the lock block 10 . Before and after the seat seal, the upper step 25 at the lower end of the boss 28 cooperates with the step 24 on the lock block 10, see Figure 8 and Figure 9 . When unsealing, lift the central tube, the lower step 26 at the lower end of the boss 28 cooperates with the step 24 on the lock block 10, see Figure 10 At this time, the lower end of the step 24 of the lock block is embedded in the annular groove 27 at the lower end of the central tube boss 28, the lock sleeve 8 compresses the lock ring 9 and shrinks to make the lock block 10 move radially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com