Vacuum test device for testing induction motor stator performance

A testing device and induction motor technology, applied in the direction of motor generator testing, etc., can solve the problems of high maintenance cost, uneven force on the guide rail, and low service life, so as to reduce the failure rate and maintenance cost, and avoid the bending of the guide rail. Folding inclination, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

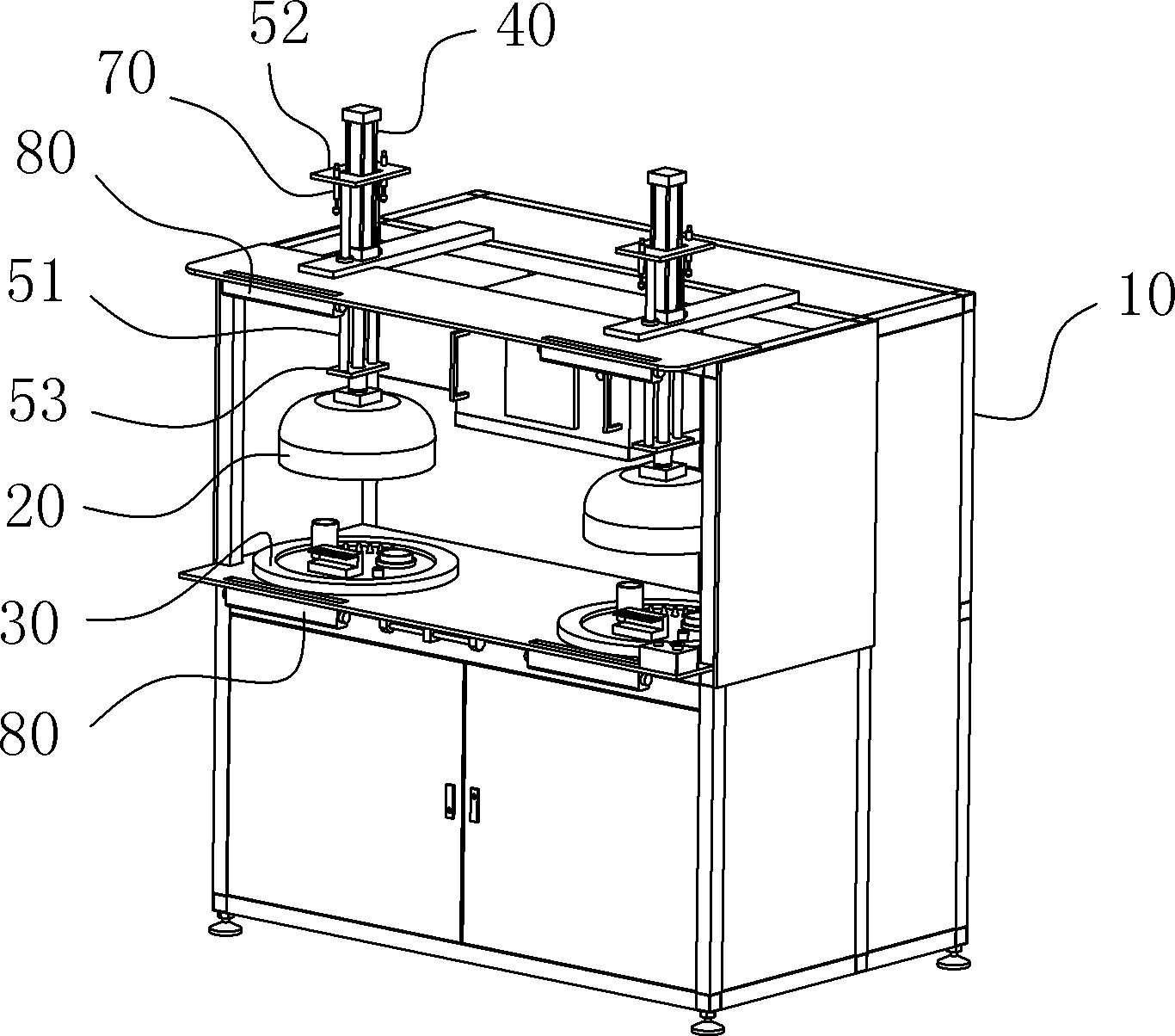

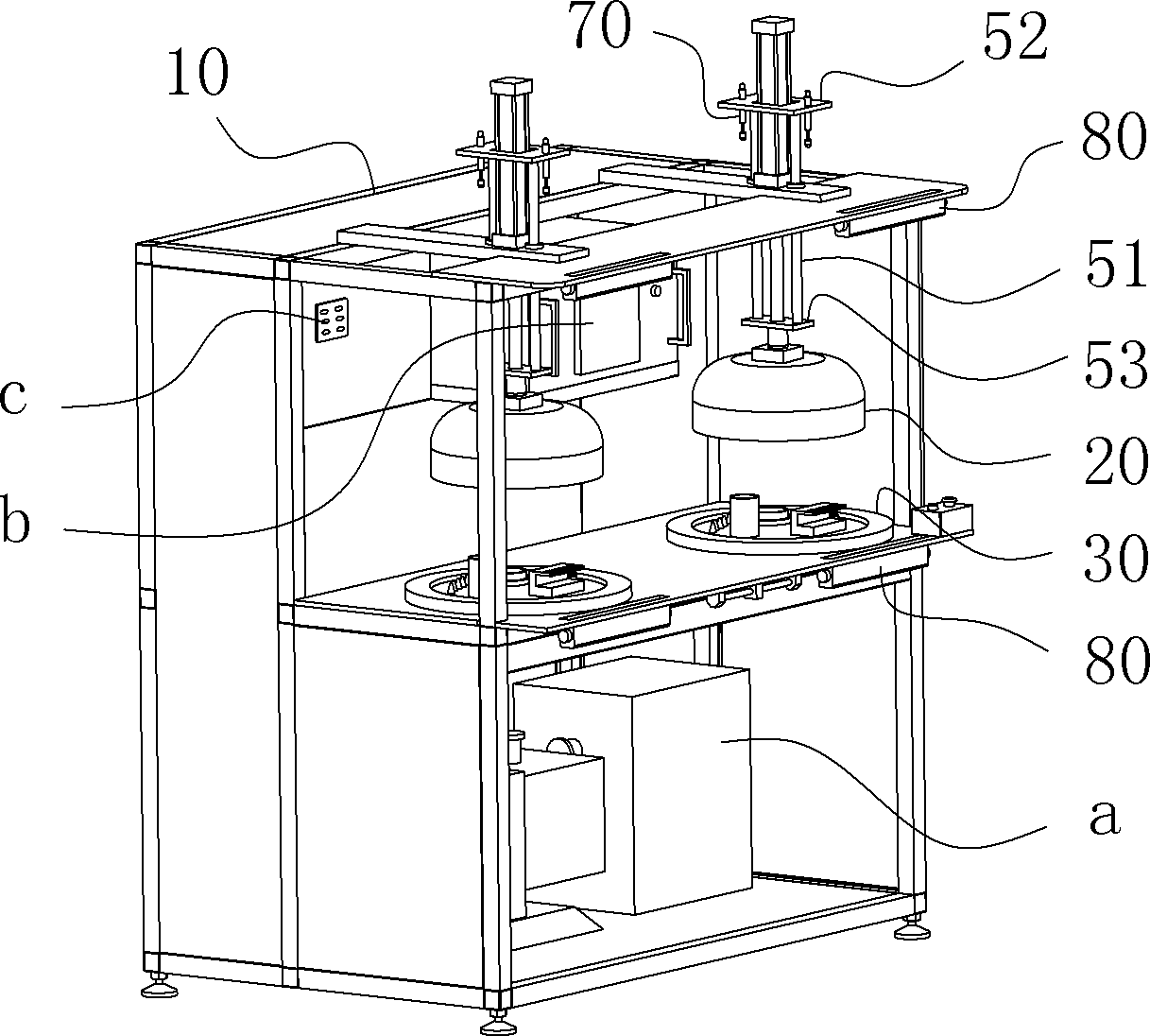

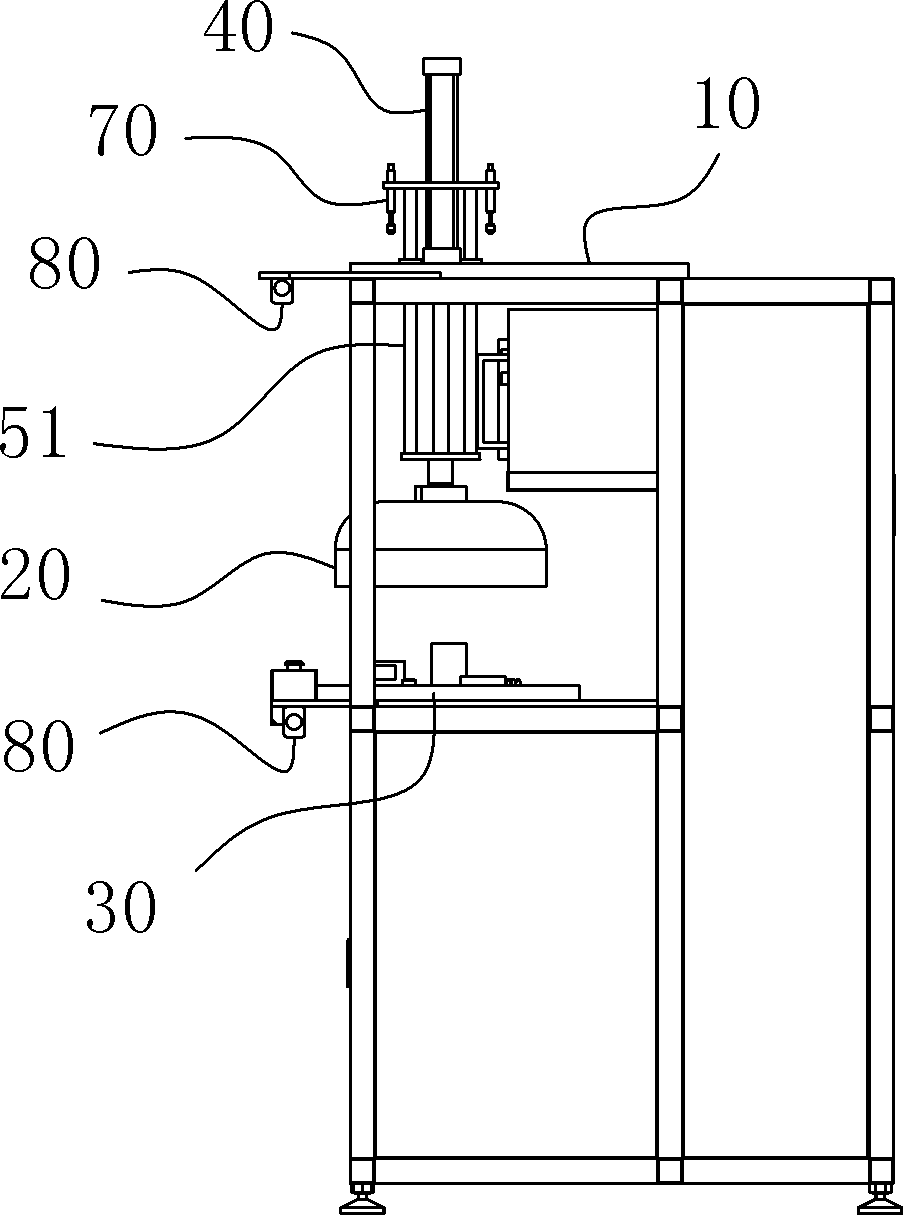

[0010] A vacuum test device for the performance of the stator of an induction motor, comprising a workbench 10 and a vacuum cover 20 suspended above the table of the workbench 10, and a sealing assembly matching the mouth of the vacuum cover 20 is arranged on the table 30. The vacuum test device also includes a vacuum pumping component a and an induction motor stator test component b, the fixed test end of the induction motor stator test component is located in the area enclosed by the sealing component 30, and the workbench 10 It is also provided with a power source 40 for driving the vacuum cover 20 to reciprocate linearly up and down and a guide part guiding the action direction of the vacuum cover 20. The guide parts are more than two and arranged symmetrically on both sides of the vacuum cover 20 cover axis. like Figure 1-4 shown.

[0011] As a further preferred version of the present invention: as Figure 4 As shown, the power source 40 is a piston cylinder, the top e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com