Control method of hydraulic pressure balance device of twenty-roller steel plate cold rolling mill transmission roller

A technology of hydraulic balance and control method, applied in the direction of back pressure device, metal rolling, metal rolling, etc., can solve the problem that the influence of interference force cannot be completely eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

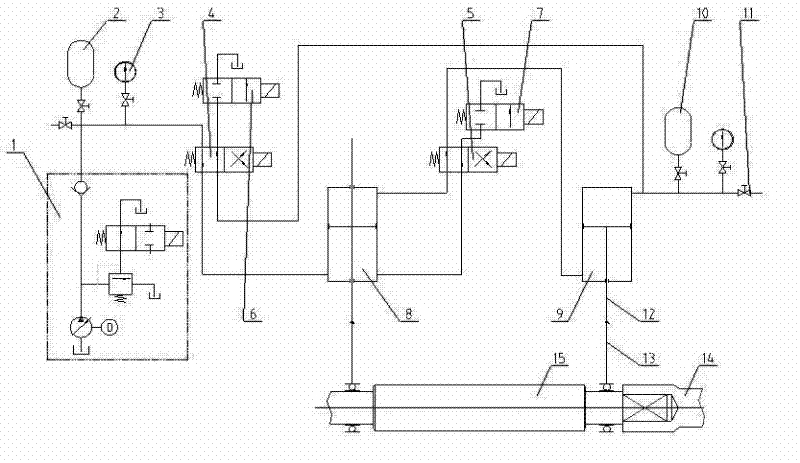

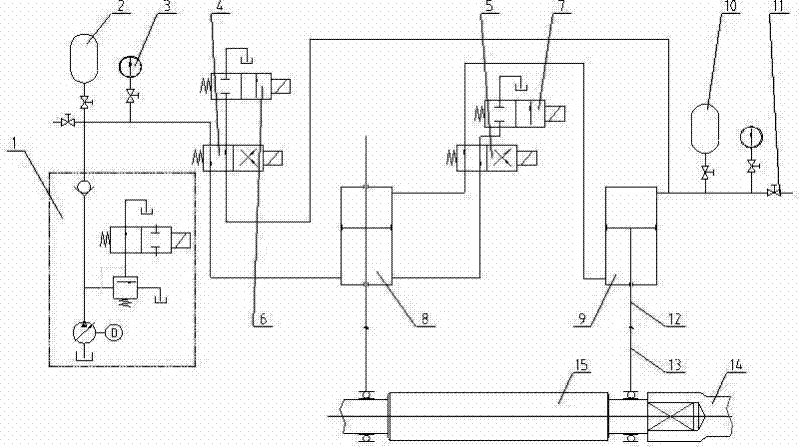

[0013] like figure 1 As shown, a hydraulic balance device for drive rolls of a twenty-high steel plate cold rolling mill, at least including a first oil cylinder 8 and a second oil cylinder 9 for controlling the balance at both ends of the drive roll, and a piston for controlling the first oil cylinder 8 and the second oil cylinder 9 The third electromagnetic reversing valve 5 and the fourth electromagnetic reversing valve 7 whose rod 12 moves up, the first electromagnetic reversing valve 4 and the second electromagnetic reversing valve which control the piston rod 12 of the first oil cylinder 8 and the second oil cylinder 9 to move down To the valve 6, the piston rods 12 of the first oil cylinder 8 and the second oil cylinder 9 are connected with the transmission roller 15 through the left and right pull rods 13. The third electromagnetic reversing valve 5 and the fourth electromagnetic reversing valve 7 are respectively connected to the upper and lower chambers of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com