Impregnated column matrix powder for diamond-impregnated bit as well as method for manufacturing matrix

A technology of impregnated diamond and carcass powder is applied in the field of alloy materials and their preparation, which can solve the problems of insufficient holding force, easy falling off, and low forming quality, and achieve high compaction density, good wear resistance, and reliable packaging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

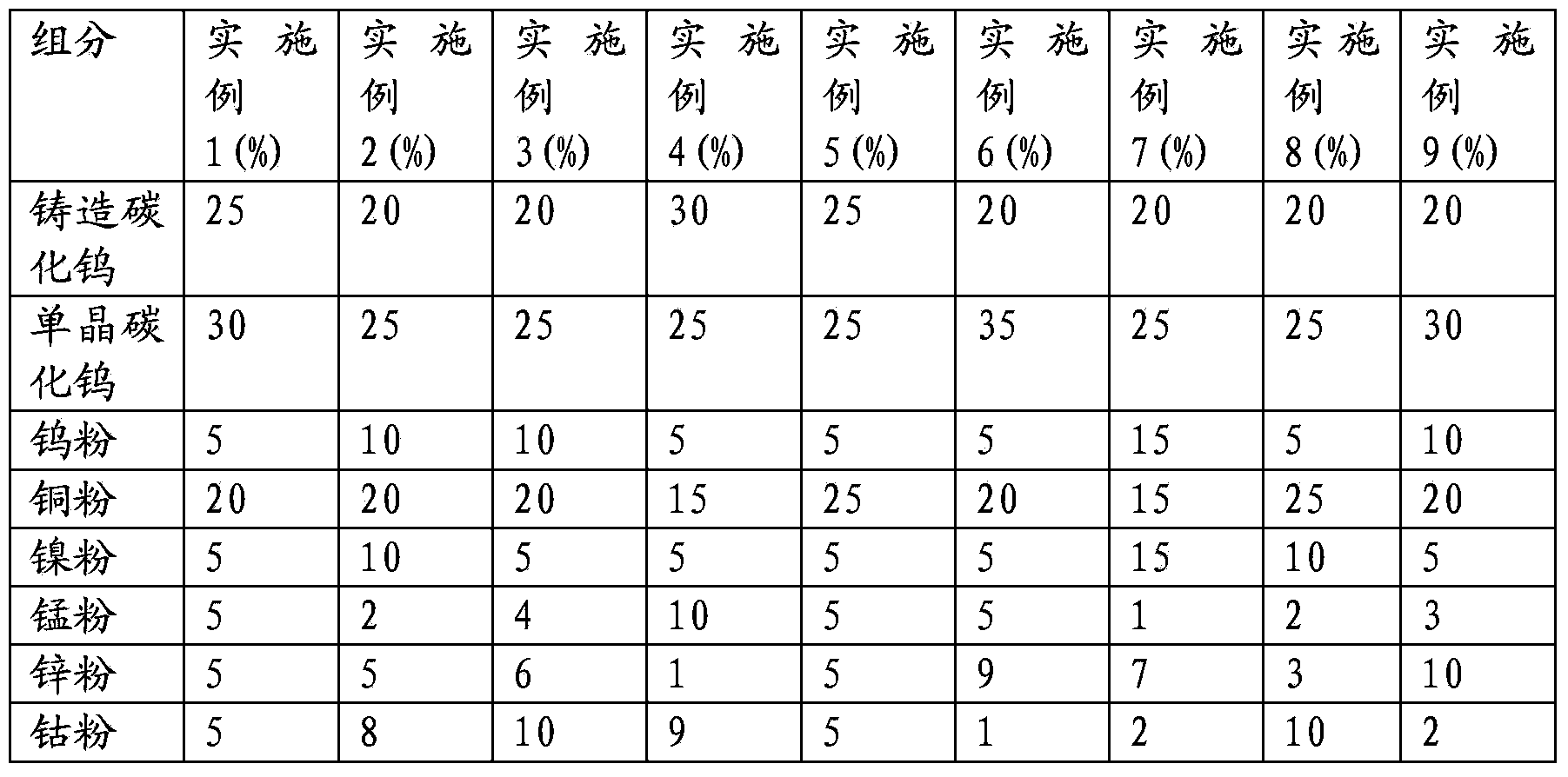

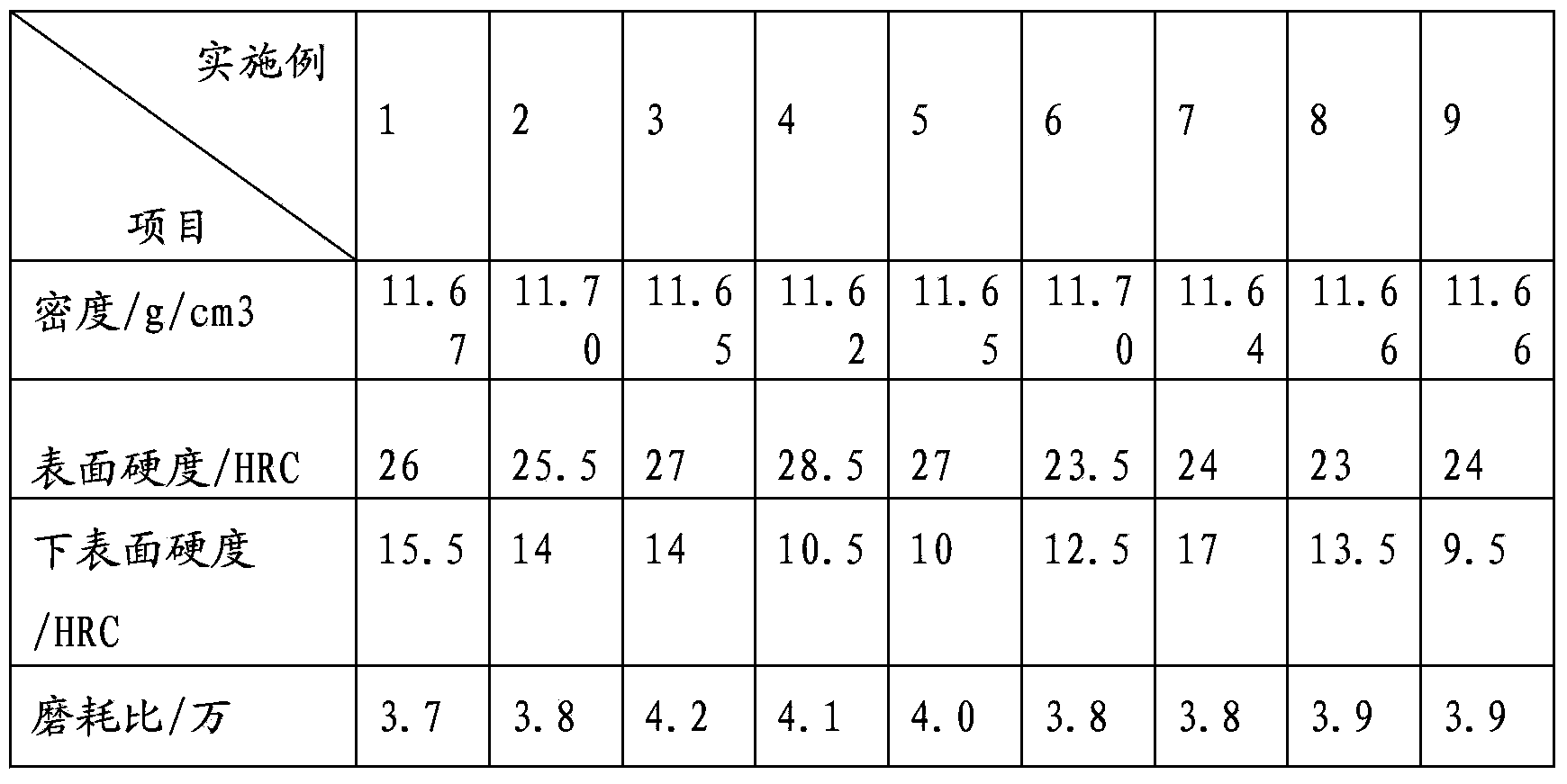

[0038] A kind of impregnated diamond drill bit is used impregnated column carcass powder, and it is mixed by following components:

[0039] 1) Coating powder composed of the following components by mass percentage: cast tungsten carbide: 25%, its particle size: 50um; single crystal tungsten carbide: 30%, its particle size: 800 mesh; tungsten powder: 5% , its particle size is: 50um; copper powder: 20%, its particle size is: 400 mesh; nickel powder: 5%, its particle size is: 800 mesh; manganese powder: 5%, its particle size is: 800 mesh; zinc powder: 5% %, its particle size is: 400 orders; Cobalt powder: 5%, its particle size is: 400 orders;

[0040] 2) Diamond: the volume ratio accounts for 25% of the above-mentioned wrapped powder, and its particle size is: 20-25 mesh. In the above-mentioned carcass powder, the diamond concentration is 100%.

[0041] A kind of manufacture method of impregnated diamond drill bit with impregnated column matrix, it comprises the following proce...

Embodiment 2

[0049] The characteristics of this embodiment are: the cast tungsten carbide: 20%; single crystal tungsten carbide: 25%; tungsten powder: 10%; copper powder: 20%; nickel powder: 10%; manganese powder: 2%; zinc powder : 5%; cobalt powder: 8%; the diamond volume ratio accounts for 30% of the above-mentioned wrapped powder. In the above-mentioned carcass powder, the diamond concentration was 120%. The particle size of cast tungsten carbide: 20um; the particle size of single crystal tungsten carbide: 200 mesh; the particle size of tungsten powder: 30um; the particle size of copper powder: 200 mesh; the particle size of nickel powder: 400 mesh; the particle size of manganese powder It is: 500 mesh; the particle size of zinc powder is: 300 mesh; the particle size of cobalt powder is: 100 mesh; the particle size of diamond is: 20 mesh. Others are the same as in Example 1.

Embodiment 3

[0051] The characteristics of this embodiment are: the cast tungsten carbide: 20%; single crystal tungsten carbide: 25%; tungsten powder: 10%; copper powder: 20%; nickel powder: 5%; manganese powder: 4%; zinc powder : 6%; cobalt powder: 10%; diamond volume ratio accounts for 17.5% of the above-mentioned wrapped powder. In the above-mentioned carcass powder, the diamond concentration was 70%. Others are identical with specific embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com