Polyethylene repackaging film material composition

A technology of polyethylene and composition, which is applied in the field of polyethylene heavy packaging film composition, can solve problems such as unstable tensile strength and puncture resistance, package body rupture, and affecting the normal production of automatic packaging lines, so as to improve the strength And anti-puncture performance, the effect of beautiful packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

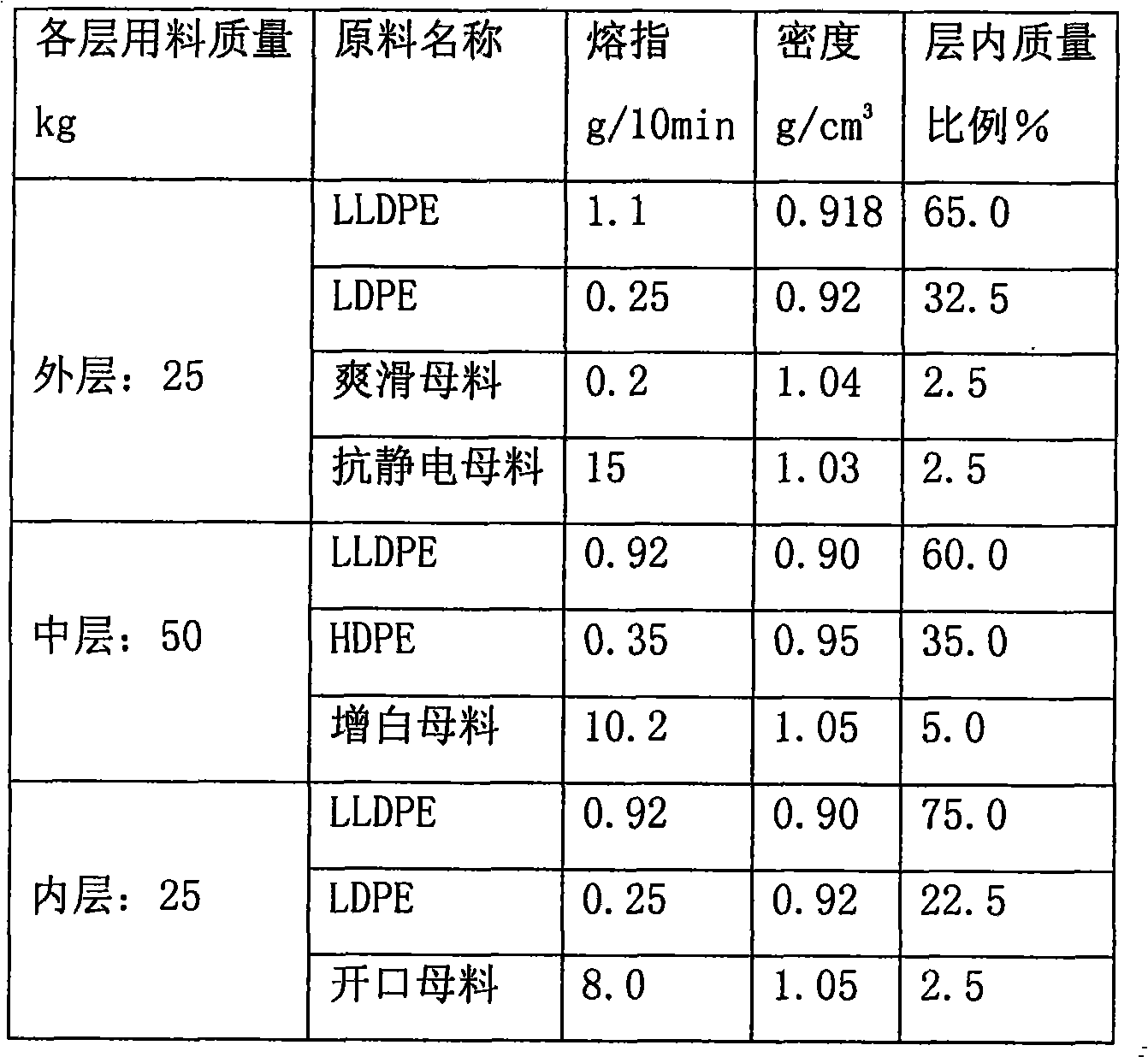

[0016] Embodiment 1: (by mass)

[0017] The formula of PE heavy packaging film material composition is:

[0018] Linear Low Density Polyethylene: 70%,

[0019] (Select the product whose comonomer is octene)

[0020] LDPE: 10%,

[0021] (Select LDPE165 from Exxon, USA)

[0022] Metallocene linear low density polyethylene: 16%,

[0023] (Choose 1018CA from Exxon, USA)

[0024] Anti-blocking agent, slip agent, antistatic agent, antioxidant, processing and heat stabilizer: According to a certain proportion, the total accounts for 4%.

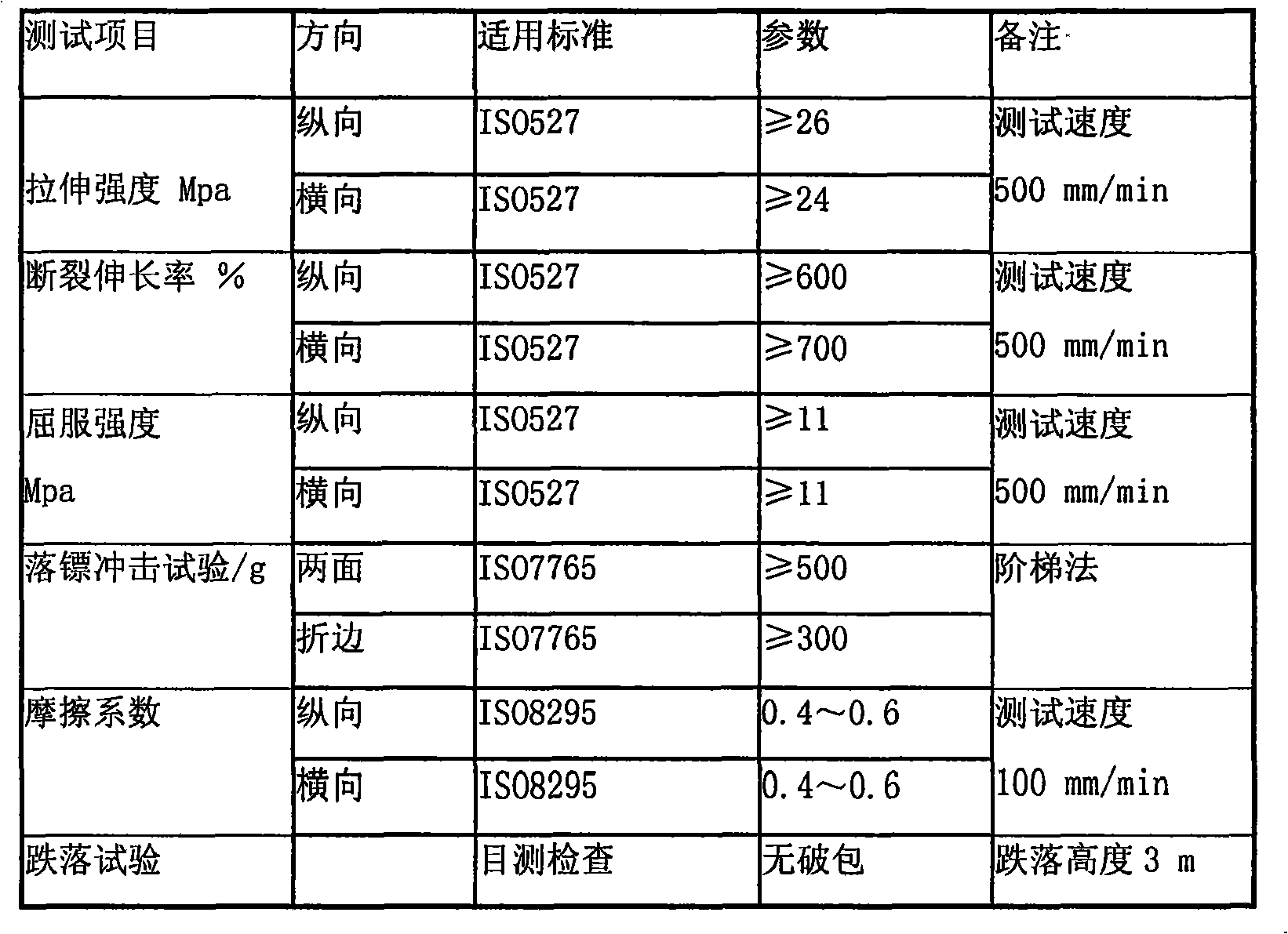

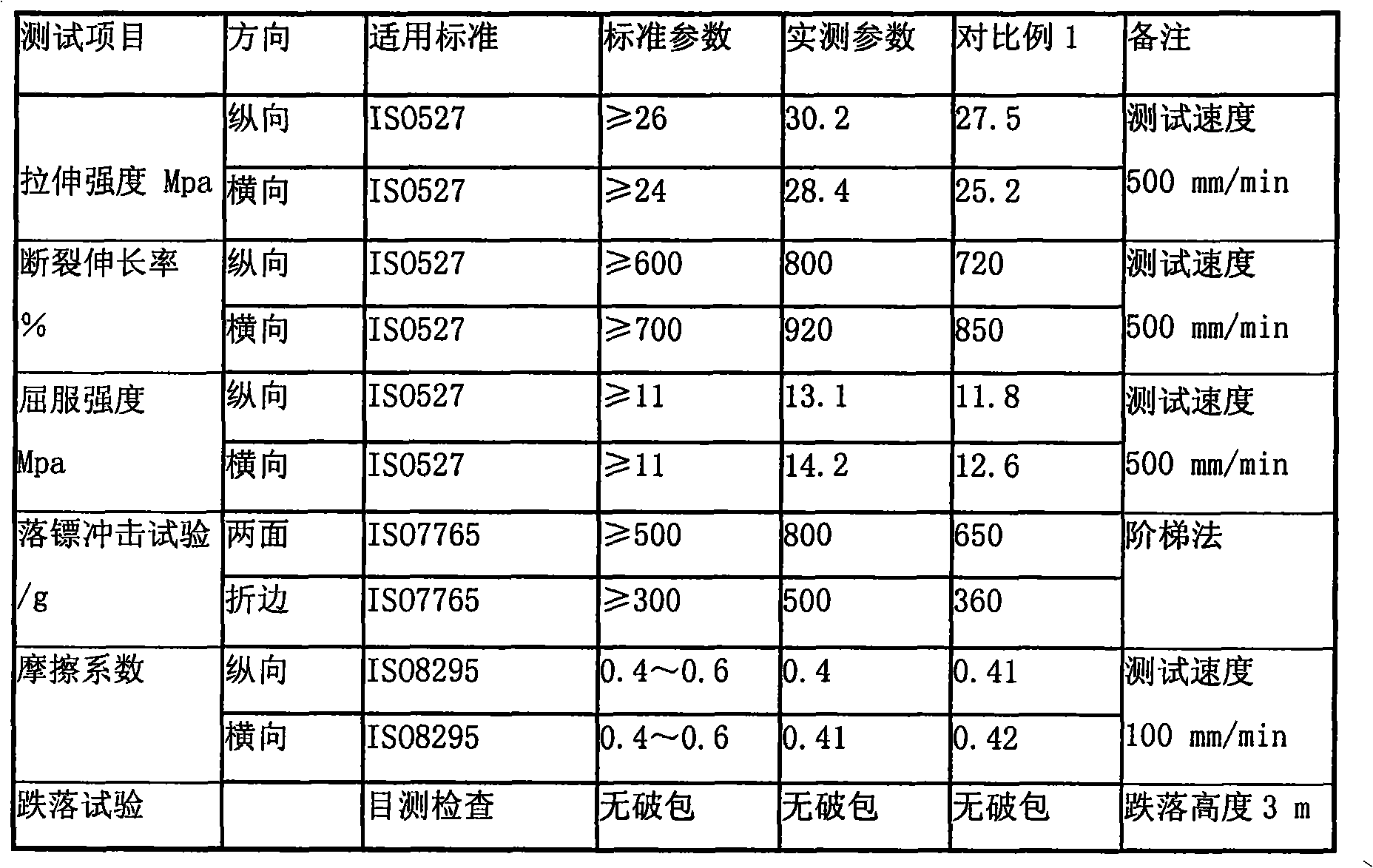

[0025] After the three-layer co-extrusion blown film production line is extruded according to the production process, the performance of the product is sampled and analyzed. The mechanical properties of the obtained product all meet the standards, and compared with other heavy packaging products, the puncture resistance and film strength are significantly improved. . The specific data are as follows:

[0026]

Embodiment 2

[0027] Embodiment 2 (by weight)

[0028] Linear Low Density Polyethylene: 80%,

[0029] (Select the comonomer as the product of hexene),

[0030] LDPE: 6%,

[0031] (Select LDPE165M from Beijing Yanhua Company),

[0032] Metallocene linear low density polyethylene: 10%

[0033] (Choose 1018CA from Exxon, USA)

[0034] Anti-blocking agent, slip agent, antistatic agent, antioxidant, processing and heat stabilizer: According to a certain proportion, the total accounts for 4%.

Embodiment 3

[0035] Embodiment 3 (by mass)

[0036] Linear Low Density Polyethylene: 60%,

[0037] (select the comonomer to be the product of octene),

[0038] LDPE: 10%,

[0039] (Select LDPE1810D from Yangzi BASF Company),

[0040] Metallocene linear low density polyethylene: 25%,

[0041] Anti-blocking agent, slip agent, antistatic agent, antioxidant, processing and heat stabilizer: According to a certain proportion, the total accounts for about 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com