Microballoon resonance filter integrated into suspension core fiber

A suspension core and filter technology, applied in cladding fibers, optical waveguides, light guides, etc., can solve the problems of large device size and low efficiency, and achieve the effects of firm packaging, high repetition rate, and low difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

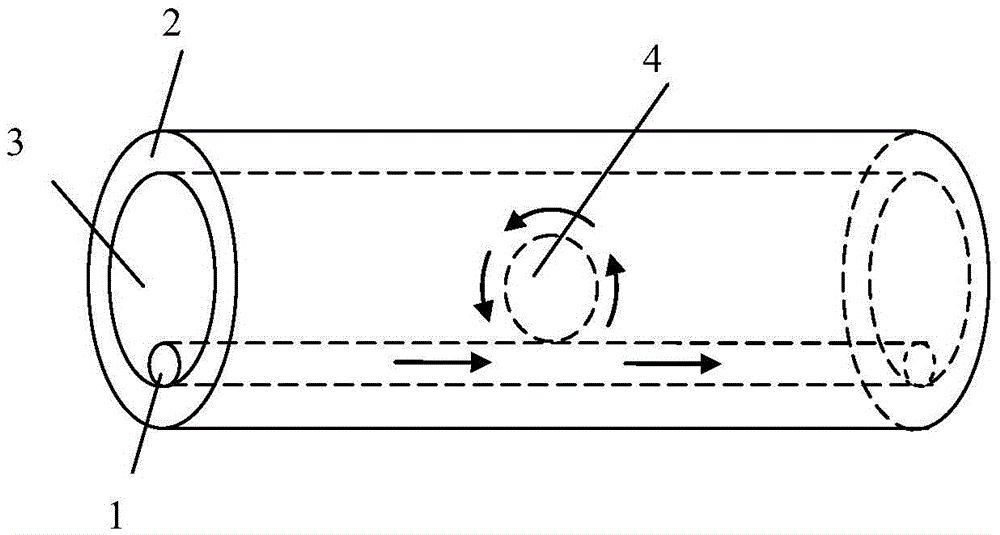

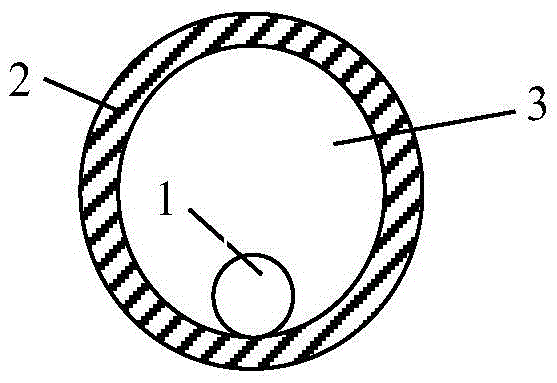

[0033] combine figure 1 , Figure 2(a), image 3 and Image 6 , a microsphere resonator filter integrated in a suspended single-core optical fiber is composed of a suspended core optical fiber 6 with a large air hole and a microsphere cavity 4 . The core diameter of the suspended core fiber is 9 microns, and the diameter of the microsphere is 100 microns. The microsphere 4 can be sucked into the air hole under a certain air pressure, and the orientation of the single-core optical fiber is suspended by rotating, so that the core position is downward, and the microsphere is heated at the position 8 of the microsphere by arc discharge or hydrogen-oxygen flame, and the heating temperature is controlled. Without deforming the fiber, the microspheres can be firmly bonded to the fiber core. The two ends of the suspension core fiber 6 are aligned with the core of the single-mode fiber 7 by an arc welding machine, and are directly coupled; Strong evanescent field, so it can resonate...

Embodiment 2

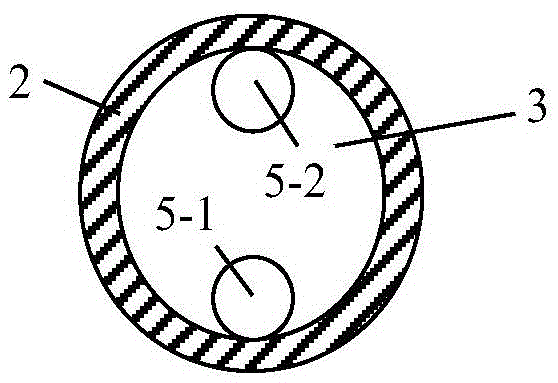

[0035] Combined with Figure 2(b), Figure 4 and Figure 5 , an upload / download filter integrated in a suspended multi-core fiber is composed of a suspended double-core fiber 6 with a large air hole and a microsphere cavity 4 . The core diameter of the suspended core fiber is 10 microns, and the diameter of the microsphere is 150 microns. The microsphere 4 can be sucked into the air hole under a certain air pressure. By rotating and suspending the orientation of the double-core optical fiber, one fiber core is positioned downward, and the microsphere is heated by arc discharge or hydrogen-oxygen flame to control the heating temperature. The heating part 9 is collapsed, and the microspheres can be firmly bonded to the two fiber cores at the same time. The two cores 5-1 and 5-2 at both ends of the suspended double-core optical fiber 6 are aligned with the core of the single-mode optical fiber 7 by a welding machine, and directly coupled; when the laser light source is coupled f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com