Standing bag box filler

A bag packing machine and stand-up pouch technology, which is applied in packaging and other directions, can solve the problems of easy dumping of stand-up bags, labor-intensive work, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

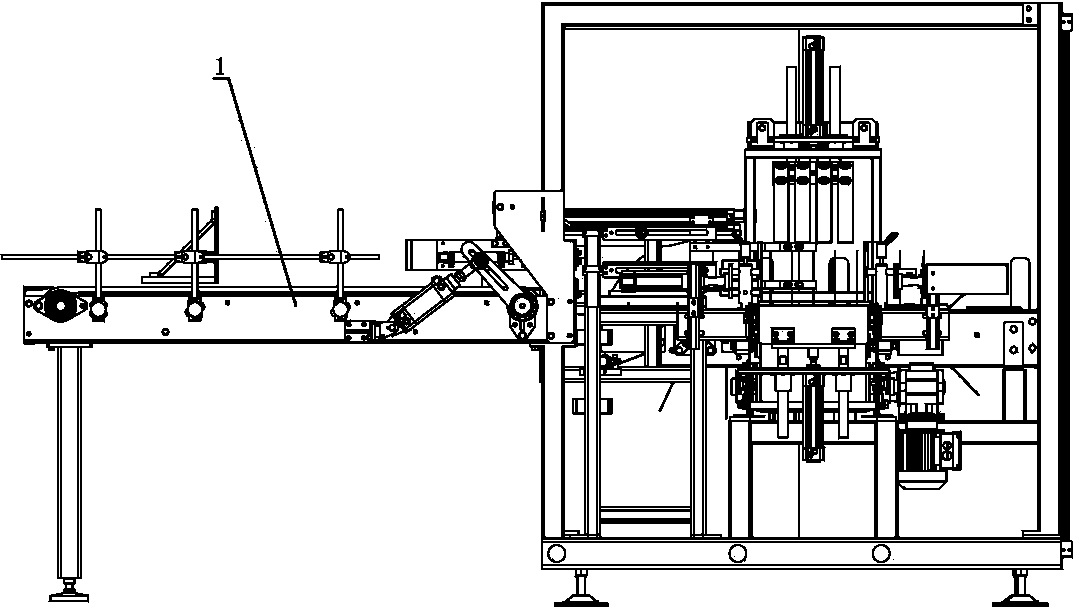

[0027] Such as Figure 1 to Figure 3 As shown, the vertical pouch packing machine includes a paper compartment conveying device 1 , a paper compartment feeding device 2 , a vertical pouch turning device 3 , and a belt feeding and finishing device 4 .

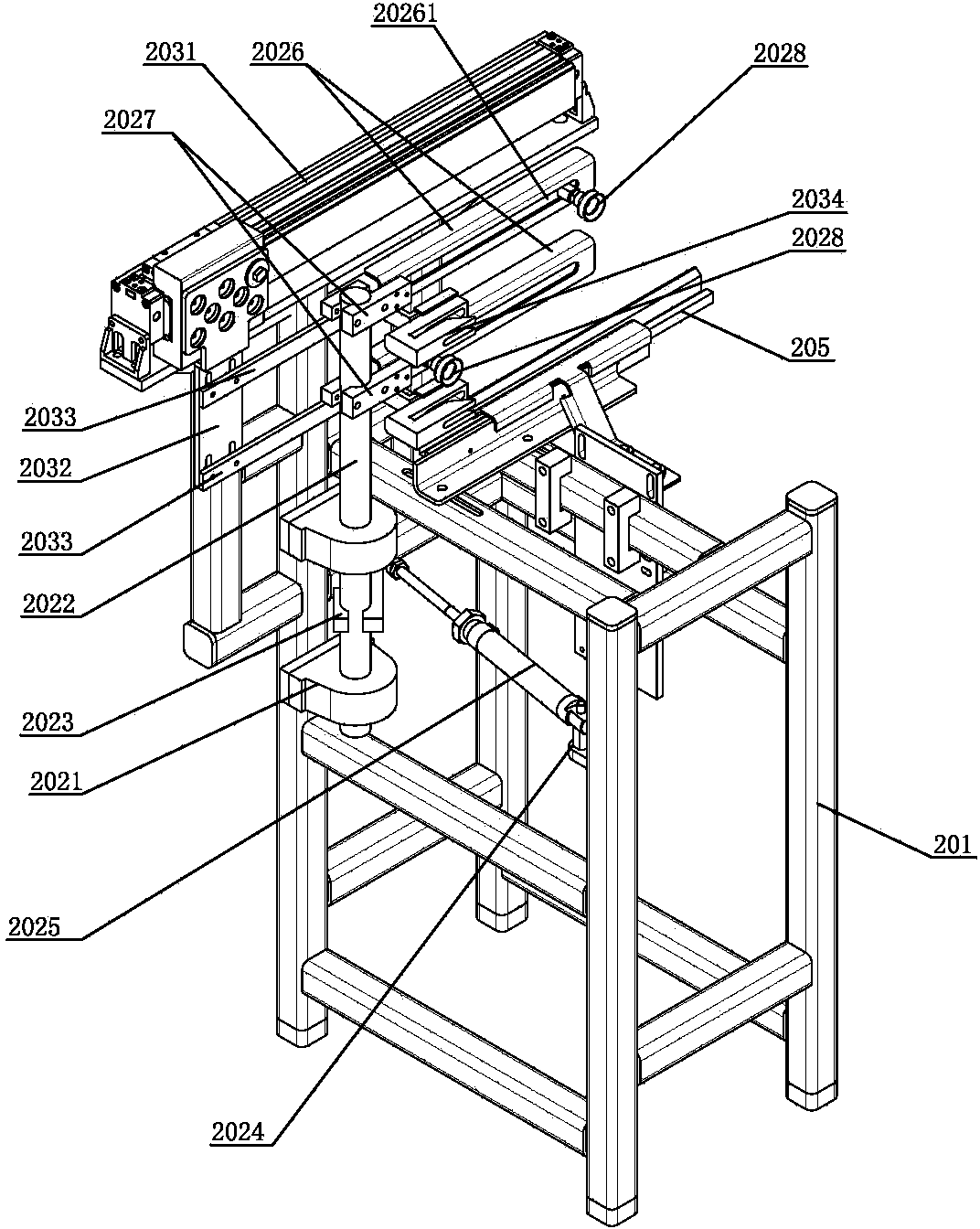

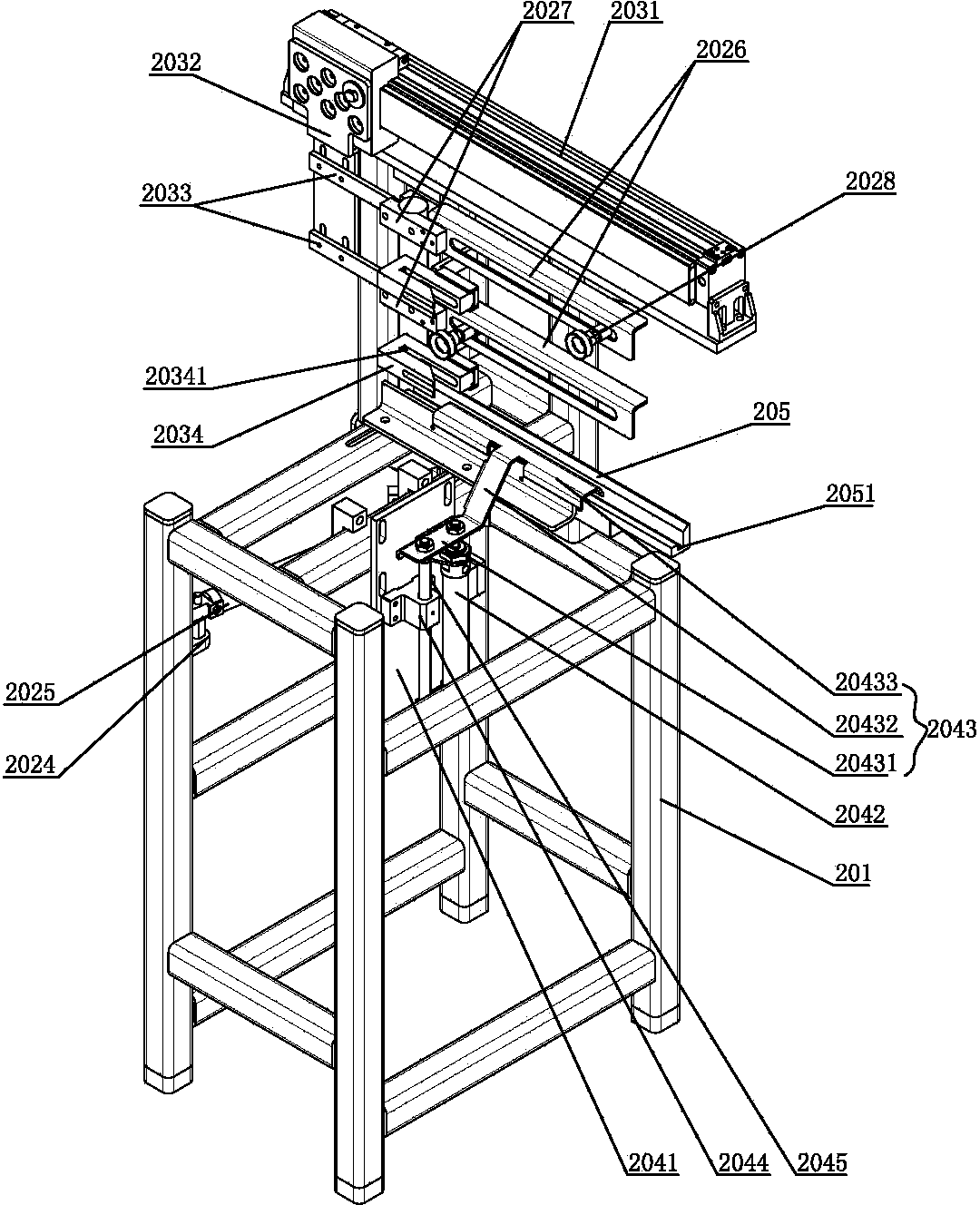

[0028] Such as Figure 4 to Figure 7 As shown, the paper separator conveying device includes a first frame 101; the first frame 101 includes a first supporting column 1011, a first left side plate 1012, a first right side plate 1013, a first end sealing plate 1014, a first left The side plate 1012 and the first right side plate 1013 are connected through the first middle beam 1015, the first end sealing plate 1014 is connected to the front ends of the first left side plate 1012 and the first right side plate 1013, and passes through the first sealing plate 1014 The front transition pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com