Day lily de-enzyme drying device and method

A technology for drying equipment and day lily, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of unfavorable packaging, large manpower consumption, ugly appearance, etc., and achieve good appearance, easy packaging, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

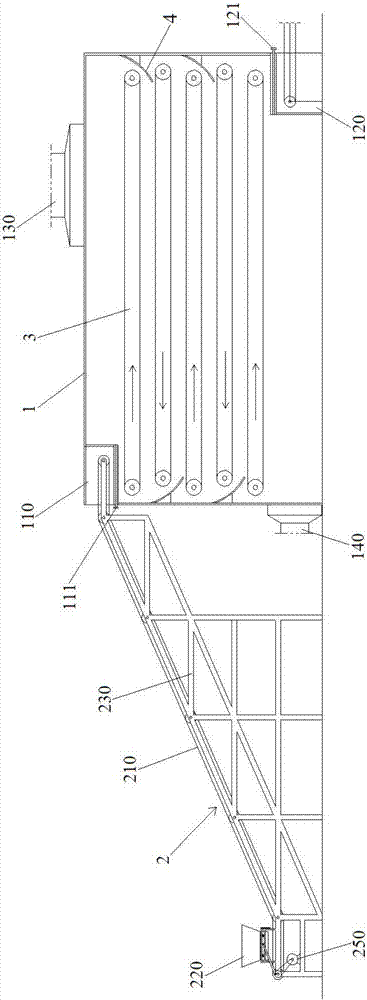

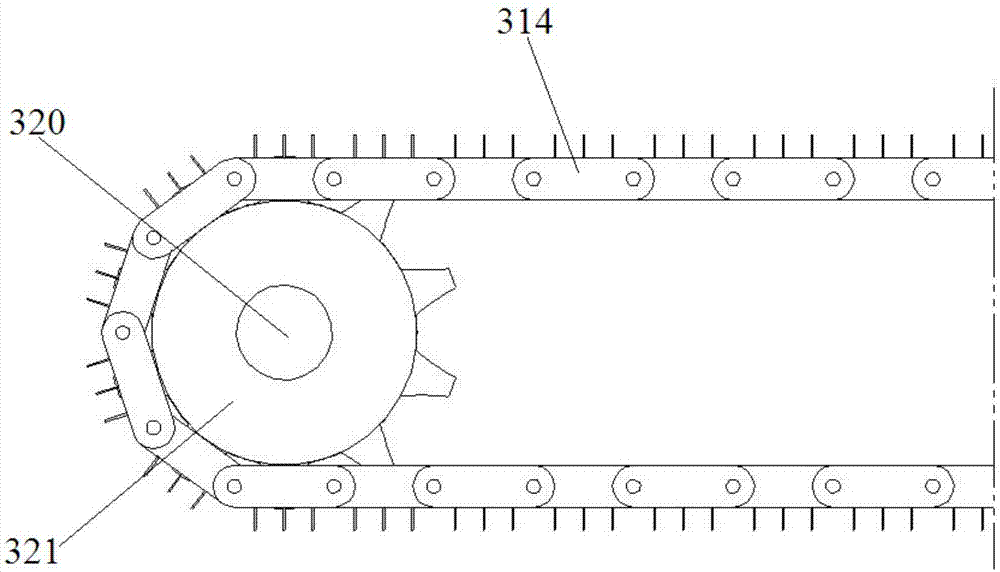

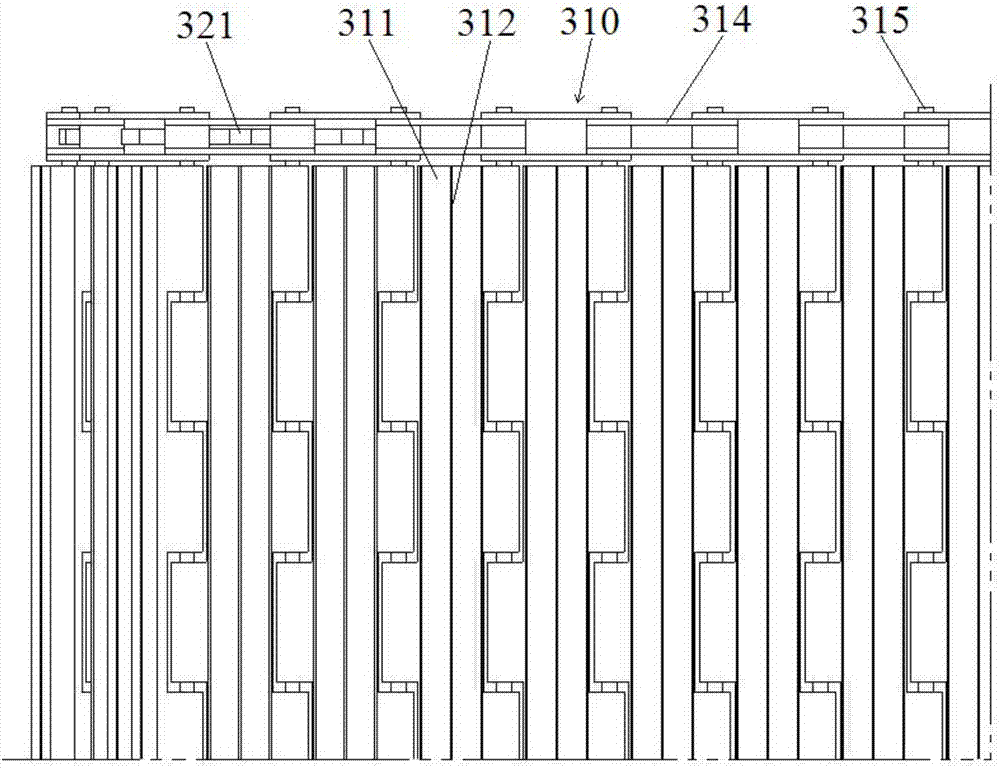

[0033] refer to figure 1 , image 3 and Figure 4 , the embodiment of the first aspect of the present invention proposes a kind of drying equipment for day lily, comprising: a drying box 1, a feeding device 2 outside the box and a plurality of plate chain conveying devices 3, the drying box 1 One side is provided with a feed port 110, the feed port 110 is provided with a feed insert 111, the other side of the drying box 1 is provided with a discharge port 120, and the discharge port 120 is provided with a There is a discharge plate 121, the top of the drying box 1 is provided with a steam exhaust port 130, the steam exhaust port 130 is connected with a moisture exhaust pipe, and the lower part of the drying box 1 is provided with a steam inlet 140, the steam inlet 140 is connected to the steam boiler through a steam pipeline; the feeding device 2 outside the box is provided with a feeding conveyor belt 210 and a lower hopper 220, and the lower hopper 220 is arranged on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com