Volute spiral spring type swing device with gap removing function

A scroll spring and oscillator technology, applied in the field of oscillators, can solve problems such as shaking of the swinging head, failure to meet the requirements, and affecting the repair effect of the water wall by the automatic welding robot, so as to avoid shaking of the swinging head and improve The effect of the repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

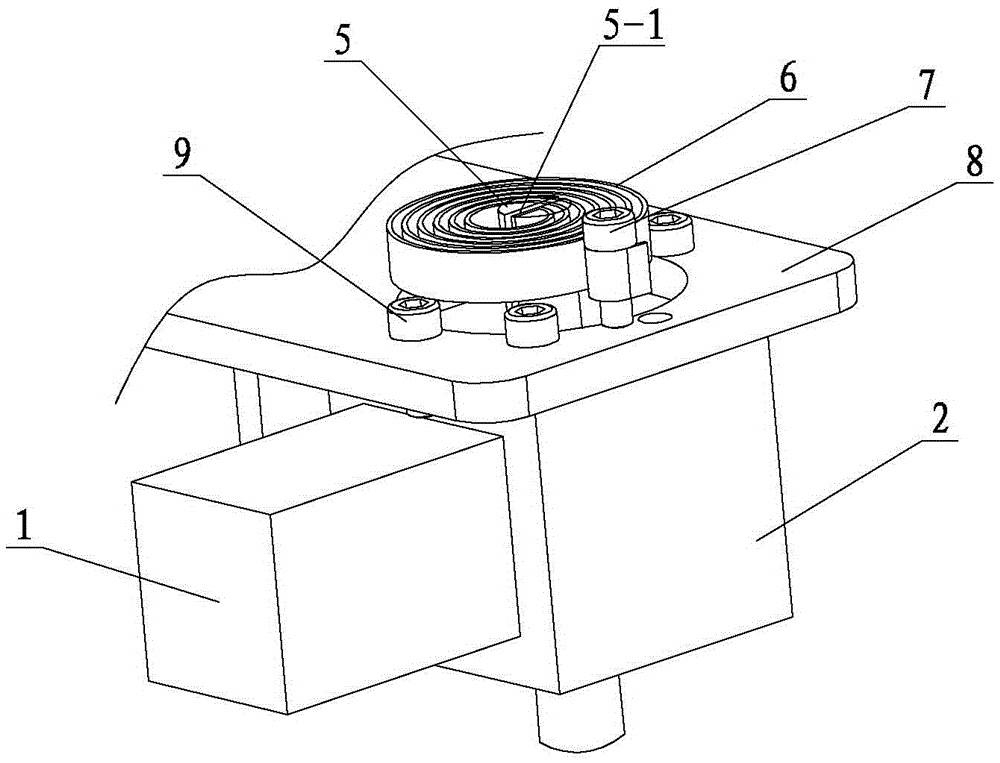

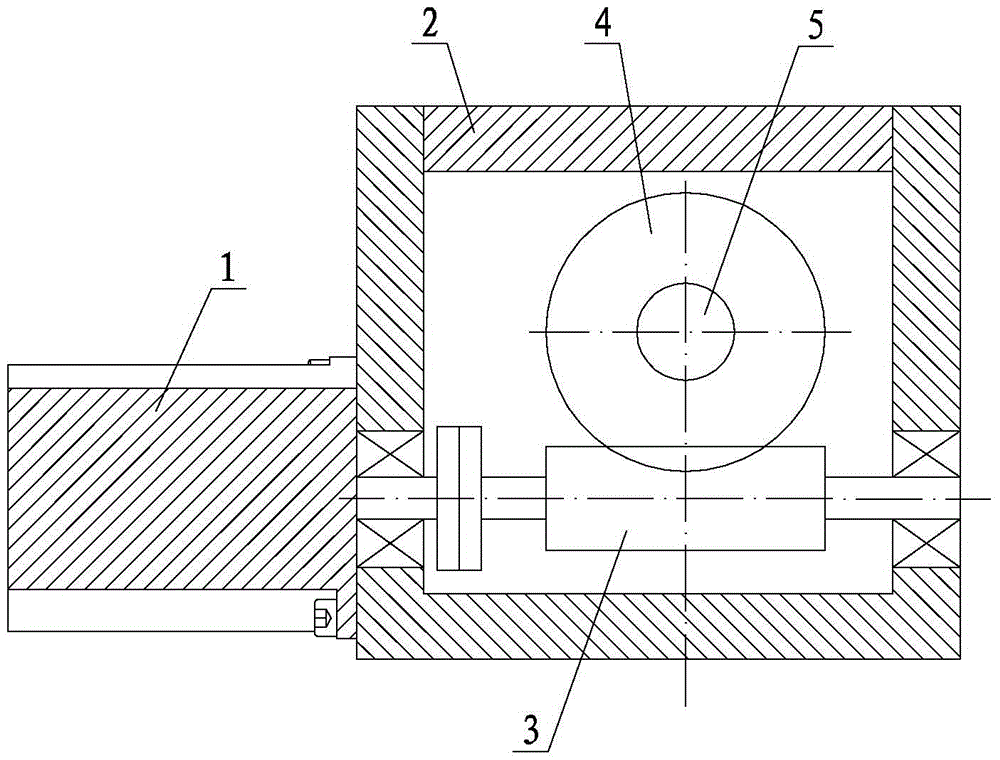

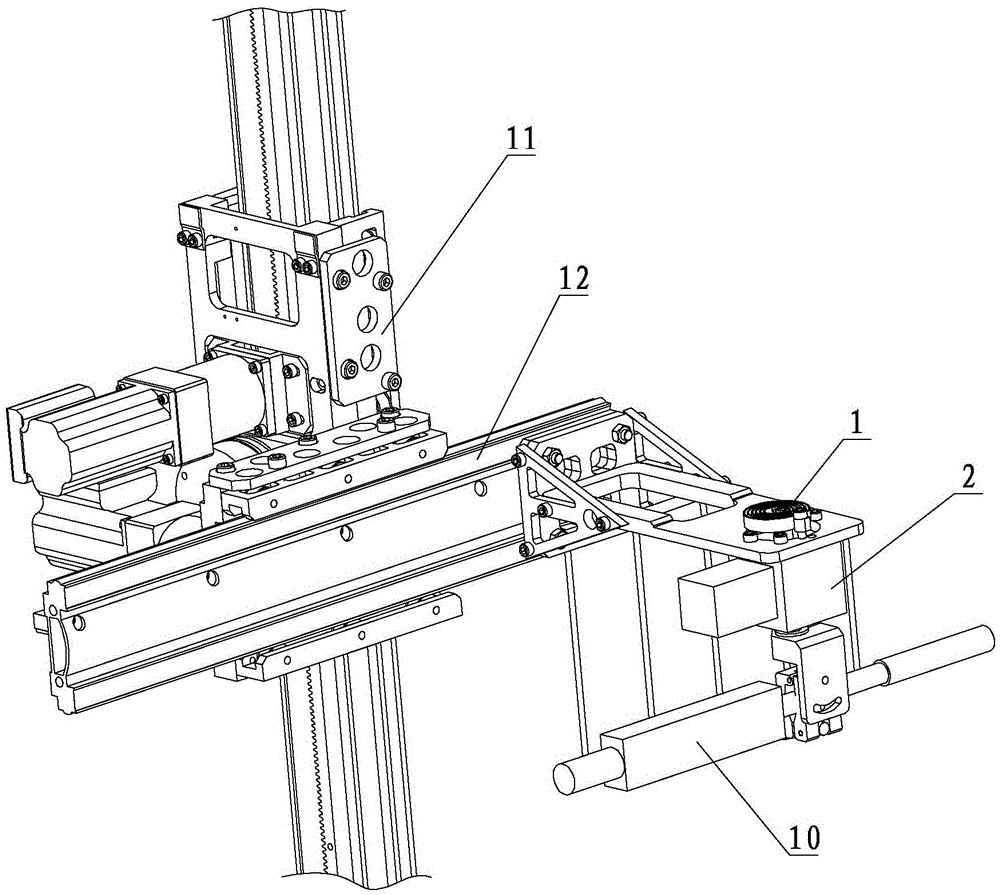

[0010] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment comprises motor 1, casing 2, worm 3, worm wheel 4, driven shaft 5, scroll spring 6, screw 7 and fixing plate 8, and motor 1 is fixedly installed outside casing 2, and worm 3 is set in the housing 2 and connected with the output shaft of the motor through a coupling, the worm wheel 4 is engaged with the worm 3, the worm wheel 4 is fixed on the driven shaft 5, and the upper end of the driven shaft 5 is provided with a gap 5- 1. The scroll spring 1 is set outside the casing 2 and wound on the driven shaft 5. The inner end of the scroll spring 6 is inserted into the gap 5-1, and the outer end of the scroll spring 6 is fixed on the screw 7. , the screw 7 is threadedly connected with the fixed plate 8, and the housing 2 is fixed on the fixed plate 8. The fixed plate 8 is fixed on the transverse guide rail 12 .

specific Embodiment approach 2

[0011] Specific implementation mode two: combination image 3 Describe this embodiment, the difference between this embodiment and specific embodiment one is that it also has at least three positioning rods 9, at least three positioning rods 9 are evenly distributed along the outer surface of the scroll spring 6, and the lower ends of the positioning rods 9 It is threadedly connected with the fixed plate 8. Other components and connections are the same as those in the first embodiment.

[0012] Working principle: Before installing the welding gun, pre-tighten the scroll spring 6; the motor 1 drives the worm 3 to rotate, the worm 3 drives the worm wheel 4 to rotate, and the worm wheel 4 drives the driven shaft 5 to rotate. Under the action of the scroll spring 6, The teeth on the worm wheel 4 and the teeth on the worm 3 are made to be in close contact with each other, thereby compensating the gap generated between the worm wheel 4 and the worm 3 during transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com