Packaging structure of scanning micromirror

A scanning micromirror and packaging structure technology, applied in the field of spectrometers, can solve the problems of easy damage to the lower printed circuit board circuit, increasing the driving voltage of the scanning micromirror chip, unsuitable for mass production of products, etc. Mass production, simple and stable packaging structure, and small distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

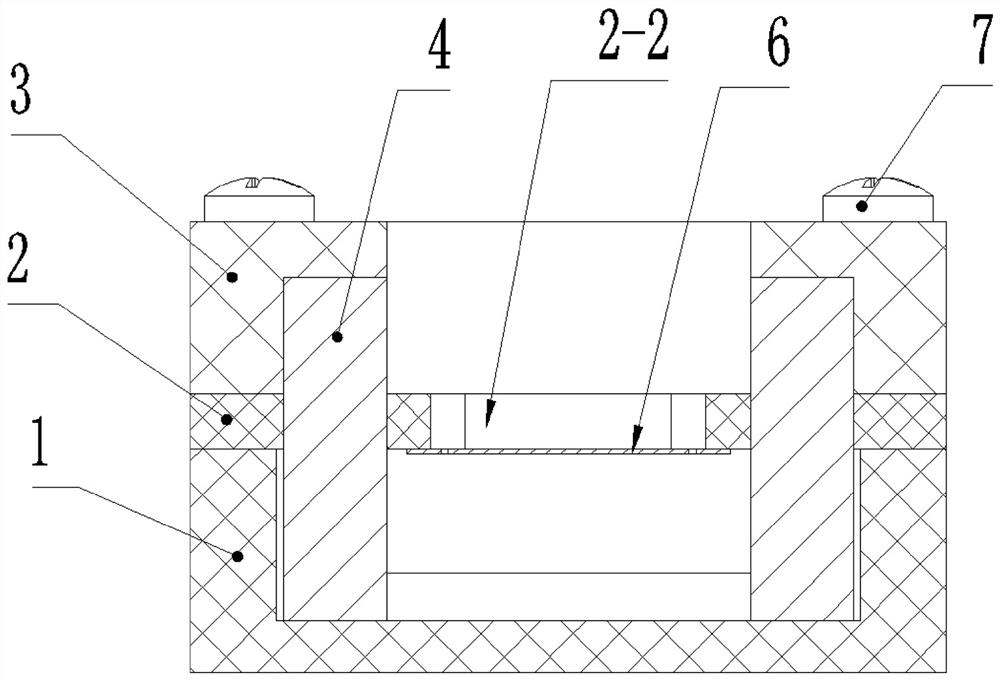

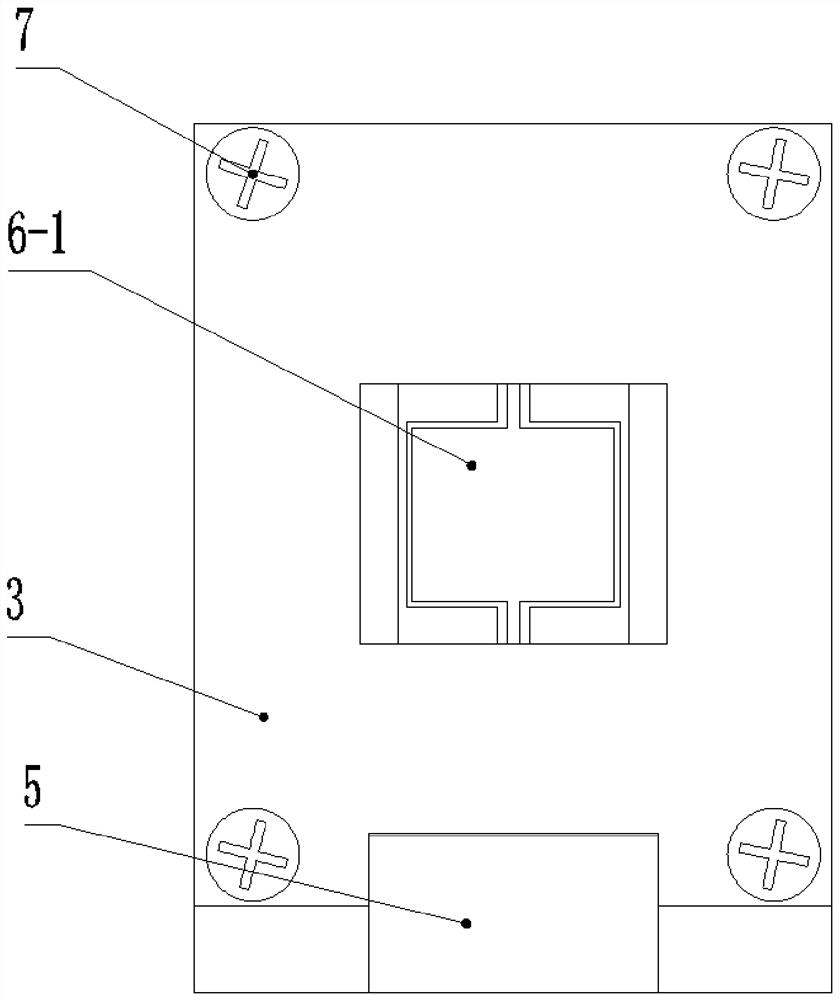

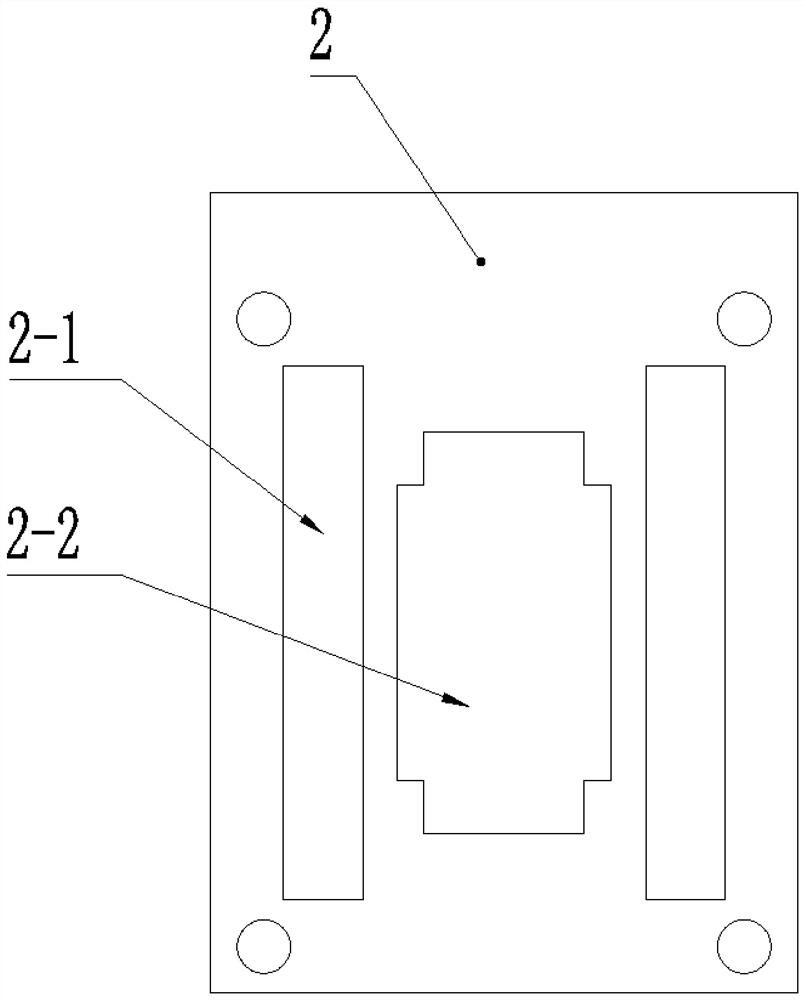

[0033] see Figure 1 to Figure 10, an encapsulation structure of a scanning micromirror, comprising a base 1 , a cavity 1 - 1 is arranged on the upper end of the base 1 , and a printed circuit board 2 is placed on the upper end of the base 1 . The middle of the printed circuit board 2 is provided with a via hole 2-2 for light to pass through, and two mounting holes 2-1 are symmetrically arranged on the left and right sides of the via hole 2-2 on the printed circuit board 2. Magnets 4 are respectively fixed in the mounting holes 2-1. The front and rear cavity walls of the cavity 1-1 of the base 1 are provided with a limit protrusion 1-2, and the left and right ends of each limit protrusion 1-2 are connected to the left and right cavity walls of the cavity 1-1. There are gaps 1-3 between them, and the lower ends of the magnets 4 in the two mounting holes 2-1 are inserted into the gaps 1-3 respectively and abut against the bottom of the cavity 1-1 of the base 1 . The fixing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com