Knitting needle bed swinging mechanism of warp knitting machine

A warp knitting machine and needle bed technology, which is applied to the field of swing motion mechanism, can solve the problems of difficult processing and manufacturing of cam mechanism, unsuitable high speed of cam mechanism, limiting the speed of warp knitting machine, etc., and achieves simple processing and manufacturing, and a wide range of travel speed ratio coefficients. , a variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

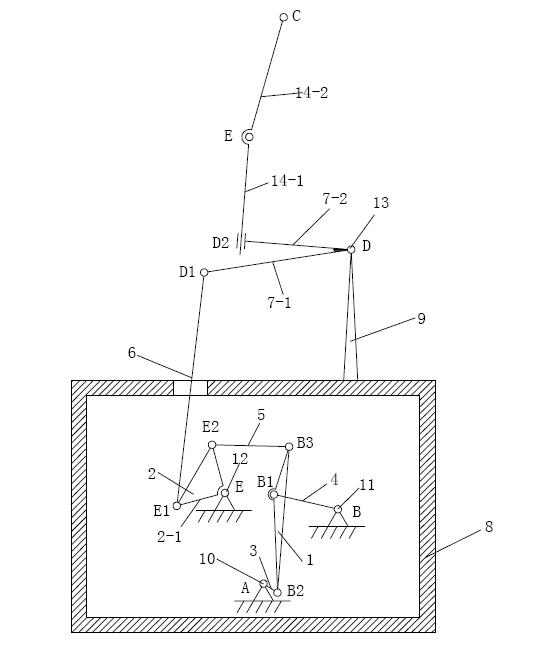

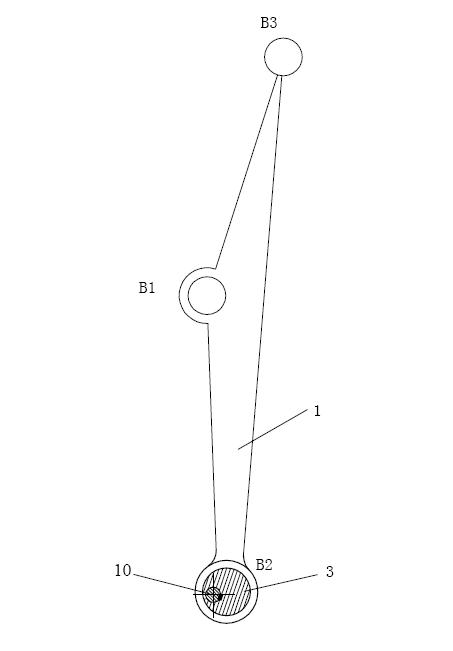

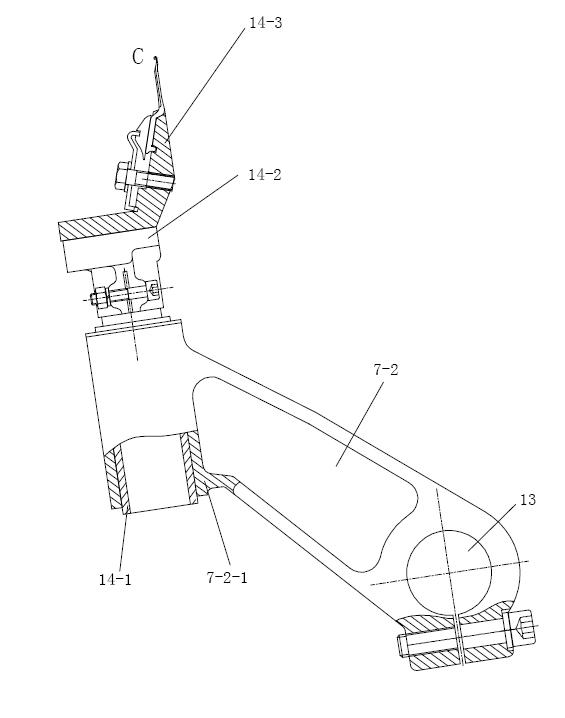

[0017] The embodiment shown in the drawings includes main shaft 10, No. 1 pin shaft 11, No. 2 pin shaft 12, pendulum shaft 13, No. 1 triangular member 1, No. 2 triangular member 2, No. 1 connecting rod 4, and No. 2 connecting rod 5. No. 3 connecting rod 6, and the needle bed 14-2 and the needle bed seat 14-1 supporting the needle bed 14-2. Described main shaft 10, No. 1 pin shaft 11, No. 2 pin shaft 12 are in the oil tank of warp knitting machine and are respectively supported by brackets. Described balance shaft 13 is supported by the support 9 that is fixed on the oil tank top of warp knitting machine. Main shaft 10, No. 1 long pin shaft 11, No. 2 long pin shaft 12 and balance shaft 13 are long shafts equal to the width of the machine. The No. 1 triangular member 1, the No. 2 triangular member 2, the No. 1 connecting rod 4, the No. 2 connecting rod 5, and the No. 3 connecting rod 6 are all arranged in the oil tank of the warp knitting machine. The above-mentioned No. 1 tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com