A double drive cart

A dual-drive, large-car technology, applied in power units, vehicle components, electric power units, etc., can solve problems such as complex installation, high manufacturing costs, troublesome maintenance, etc., to reduce installation difficulty, reduce maintenance costs, and reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The reference signs and components involved in the accompanying drawings are as follows:

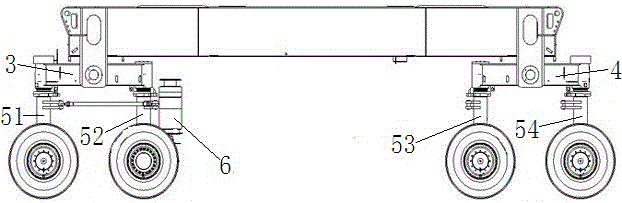

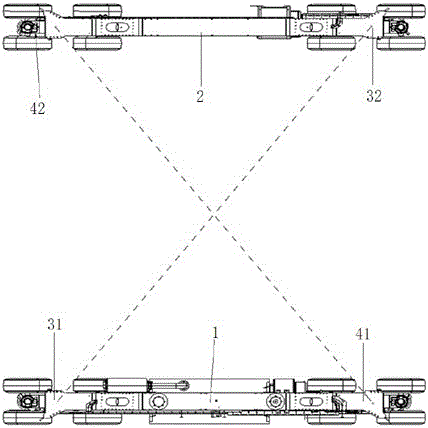

[0019] 1. RTG front beam 2. RTG rear beam 3. Balance beam that provides driving force when walking

[0020] 31. Balance beam 1 that provides driving force when walking 32. Balance beam 2 that provides driving force when walking

[0021] 4. A balance beam that provides support when walking 41. A balance beam that provides support when walking

[0022] 42. Balance beam 2 that provides support when walking 51. Steering arm 1

[0023] 52. Steering arm two 53. Steering arm three

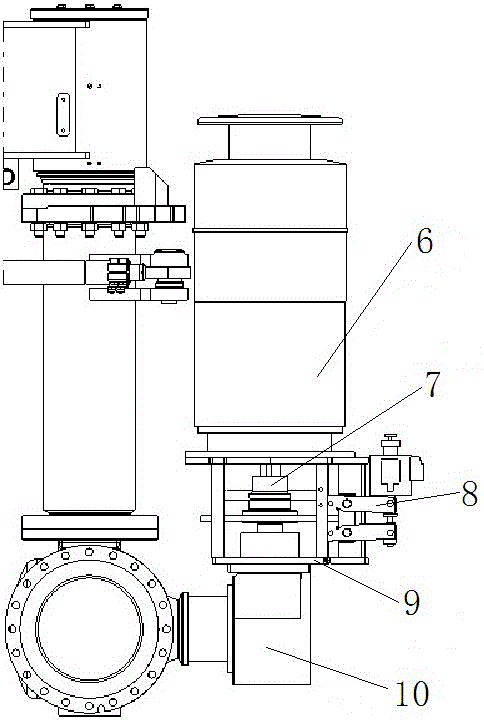

[0024] 54. Steering arm four 6. Travel drive motor

[0025] 7. Elastic coupling with brake disc 8. Caliper disc brake

[0026] 9. Steel structure support 10. Drive axle

[0027] as attached image 3 Shown is a schematic diagram of the overall structure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com