Using method of horizontal type oil production and gas exhaust synchronous production device

A production device and horizontal technology, which is applied in the field of horizontal oil production and exhaust synchronous production devices, can solve problems such as power consumption, hidden dangers, and natural gas without hydrogen sulfide removal, and achieve the effect of avoiding the drop of dynamic liquid level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

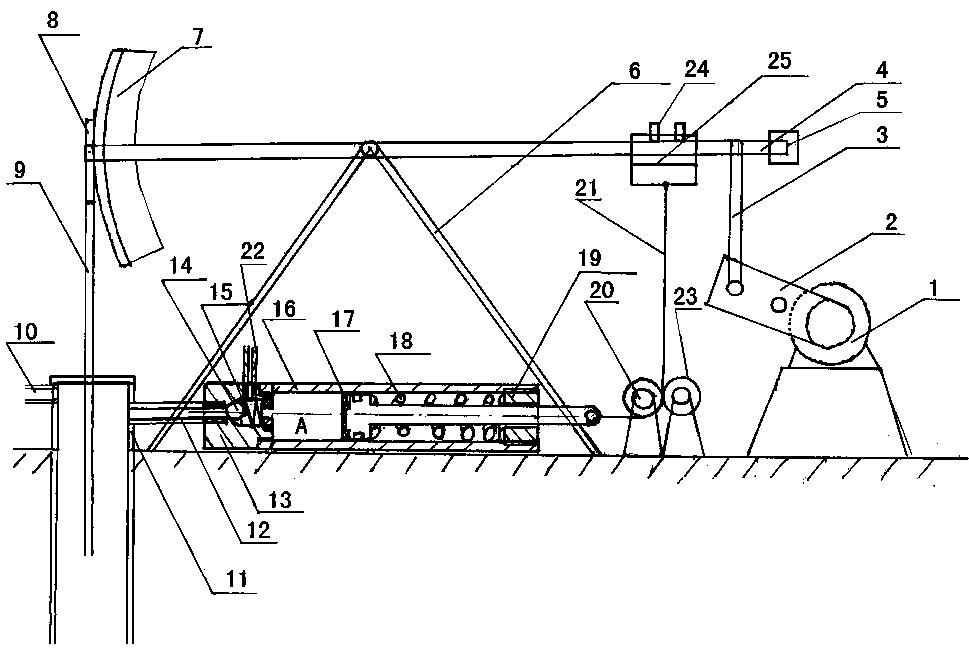

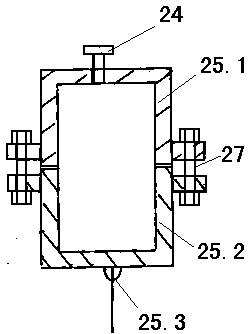

[0031] Embodiment 1, with reference to attached figure 1 , a kind of horizontal synchronous production device for oil extraction and exhaust mentioned in the present invention, its technical scheme is: comprise motor 1, power arm 2 of pumping unit, power connecting rod 3, beam 4, counterweight 5 of pumping unit, pumping unit Oil unit support 6, pumping unit donkey head 7, rope hanger 8, sealing polished rod 9, oil outlet 10, wellhead connecting nipple 11, motor 1 is connected to one end of power connecting rod 3 through the power arm 2 of the pumping unit, The other end of the power link 3 is connected to the rear side of the beam 4, and the other end of the beam 4 is connected to the donkey head 7 of the pumping unit. The middle part of the beam 4 is supported on the top of the support 6 of the pumping unit, and the end of the beam 4 is set There is a counterweight 5 of the pumping unit, and the donkey head 7 of the pumping unit is connected to the sealed polished rod 9 throu...

Embodiment 2

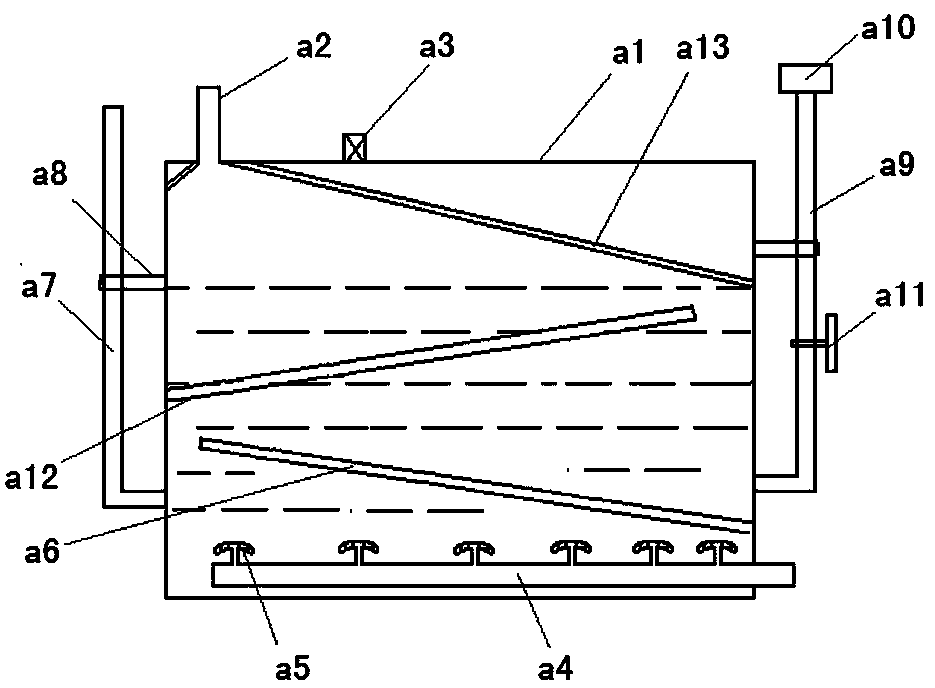

[0044] Embodiment 2, with reference to attached Figure 5 The difference between this embodiment and Embodiment 1 is that there are a plurality of ventilation pipes a14 distributed on the lower baffle plate a6 and the middle baffle plate a12, so that a small amount of gas enters the middle baffle plate a12 through the lower baffle plate a6 Below, also increases the gas and H 2 SO 3 The contact quantity of the solution; in addition, the distribution density of the umbrella-shaped spray heads a5 arranged on the air intake pipe a4 is also gradually reduced from right to left, that is, the spacing is getting larger and larger, so that the natural gas and sulfurous acid can be carried out better. In addition, in order to increase the number of air bubbles generated by the vent pipe, a stainless steel mesh can be placed on the top of the vent pipe, refer to the attached Figure 8 , increase the number of bubbles and increase the contact area with the liquid.

Embodiment 3

[0045] Embodiment 3, with reference to Figure 6 , the present invention differs from Embodiments 1 and 2 in that it does not need to be provided with a stay cord anti-off wheel 23, and the structure adopted is as follows: the stay cord can be directly connected to the counterweight 5 through the movable pulley 26, and there is no need to install a stay cord for positioning Block 25, the position that requires counterweight to install just meets the position requirement of stay rope at this moment; When the end of the beam of the oil machine goes down, the pull rope moves downward, and the return spring 18 is doing a return action. In this way, the pull rope on the side of the fixed pulley is recovered, and the torsion spring roller on the side of the auxiliary fixed pulley also drives the pull rope to recover , so that the pull rope does not fall off from the fixed pulley; when the beam goes up, one end of the pull rope pulls the suction piston to squeeze the return spring, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com