Hanging basket track beam walking method

A technology of track beams and tracks, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increasing construction costs and hoisting operation risks, track misalignment, large pulling or pushing, etc., to reduce construction costs And the risk of hoisting operation, reducing the procedures for obtaining evidence and submitting approval, and avoiding the effect of track damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

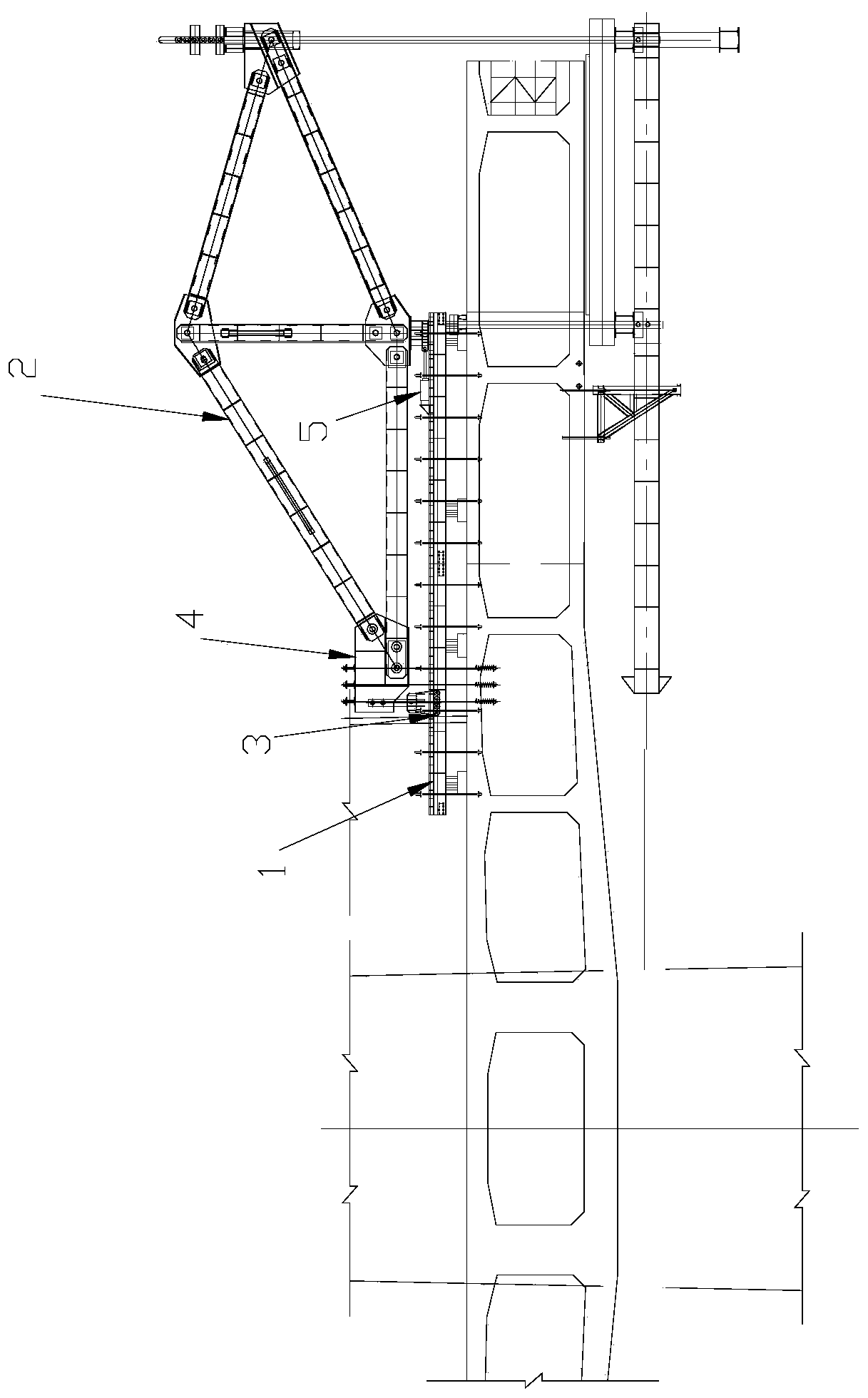

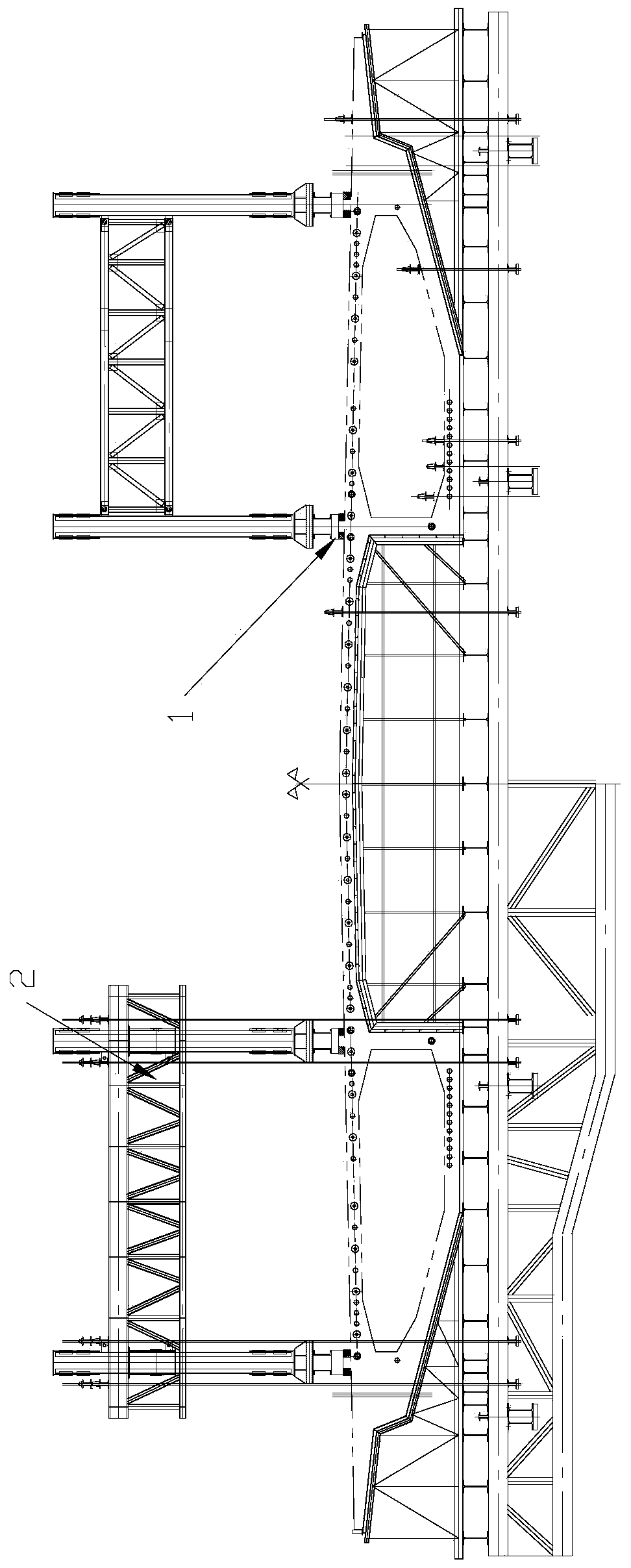

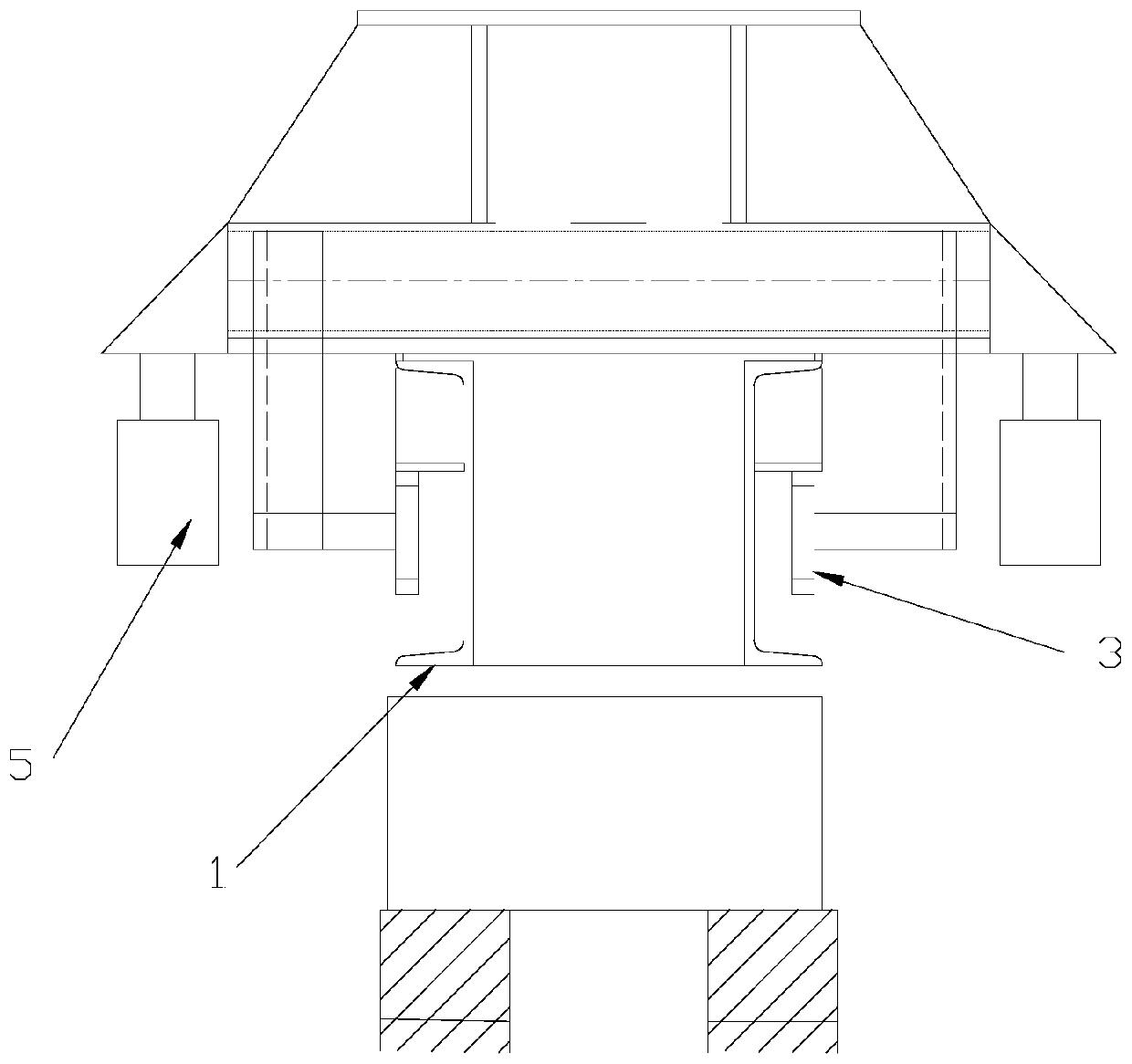

[0023] refer to Figure 1 to Figure 3 , the present invention is a kind of hanging basket track beam traveling method, it comprises the following steps:

[0024] S1: When the box girder concrete is poured in the hanging basket, the front and rear fulcrums at the bottom of the hanging basket 2 are supported on the top surface of the box girder section of the previous section through the backing plate + steel pier, and the connection height is pre-buried in the previous section. The finish-rolled threaded steel bar in the segmental box girder section is used to anchor the anchor seat 4 at the rear end of the hanging basket with the high-end finished-rolled threaded steel bar.

[0025] S2: After the concrete box in this section is poured, and the strength meets the design, the permanent longitudinal prestressed tendons are stretched and grouted, and the bottom formwork and side formwork of the hanging basket 2 are demoulded, and the hanging basket 2 is ready to move forward longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com