Culvert trolley

A trolley and culvert technology, applied in the field of culvert trolleys, can solve the problems of long construction period, difficult positioning, and high requirements for plate and plate adjustment operations, and achieve the effects of convenient use, efficient manufacturing, and firm and reliable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

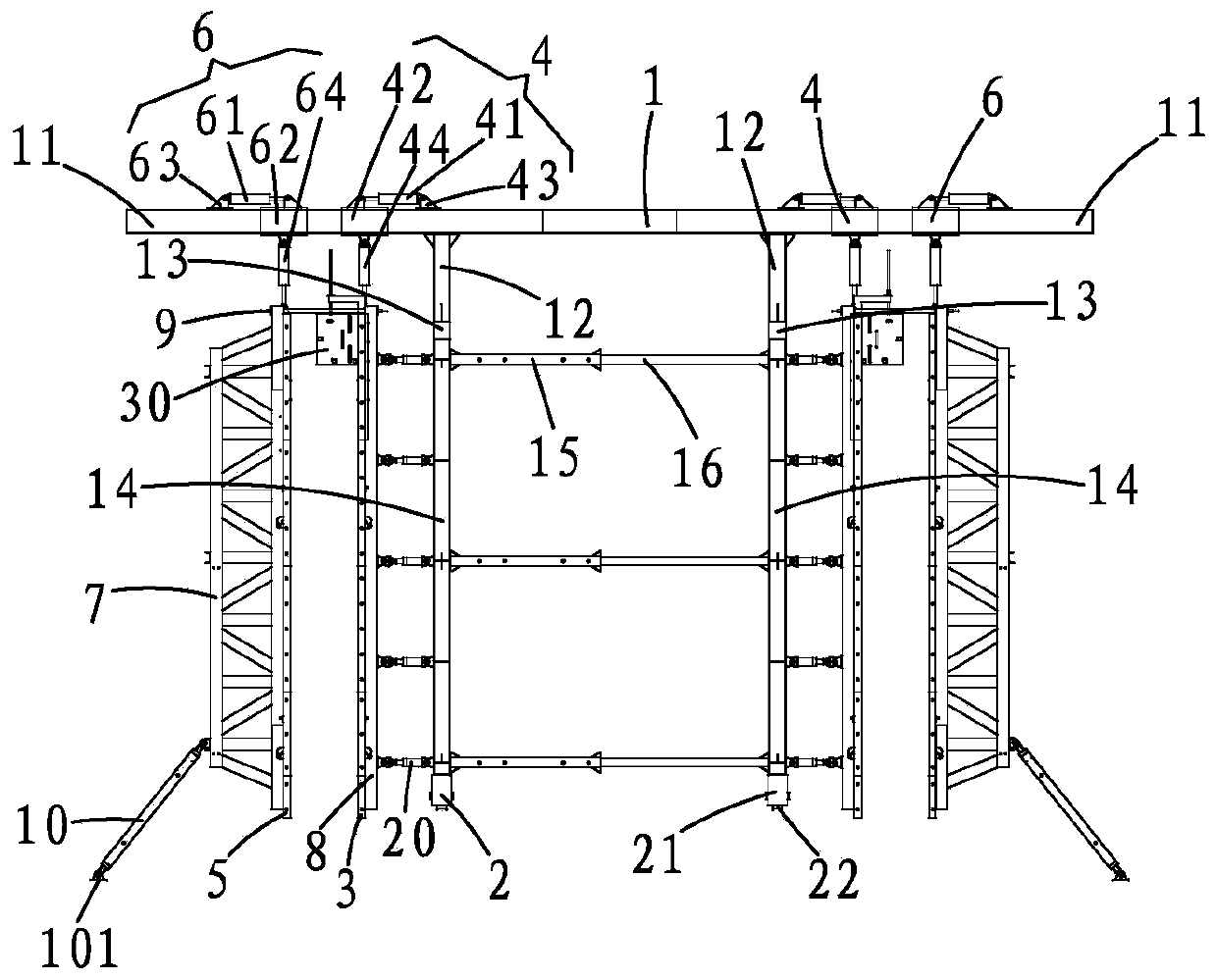

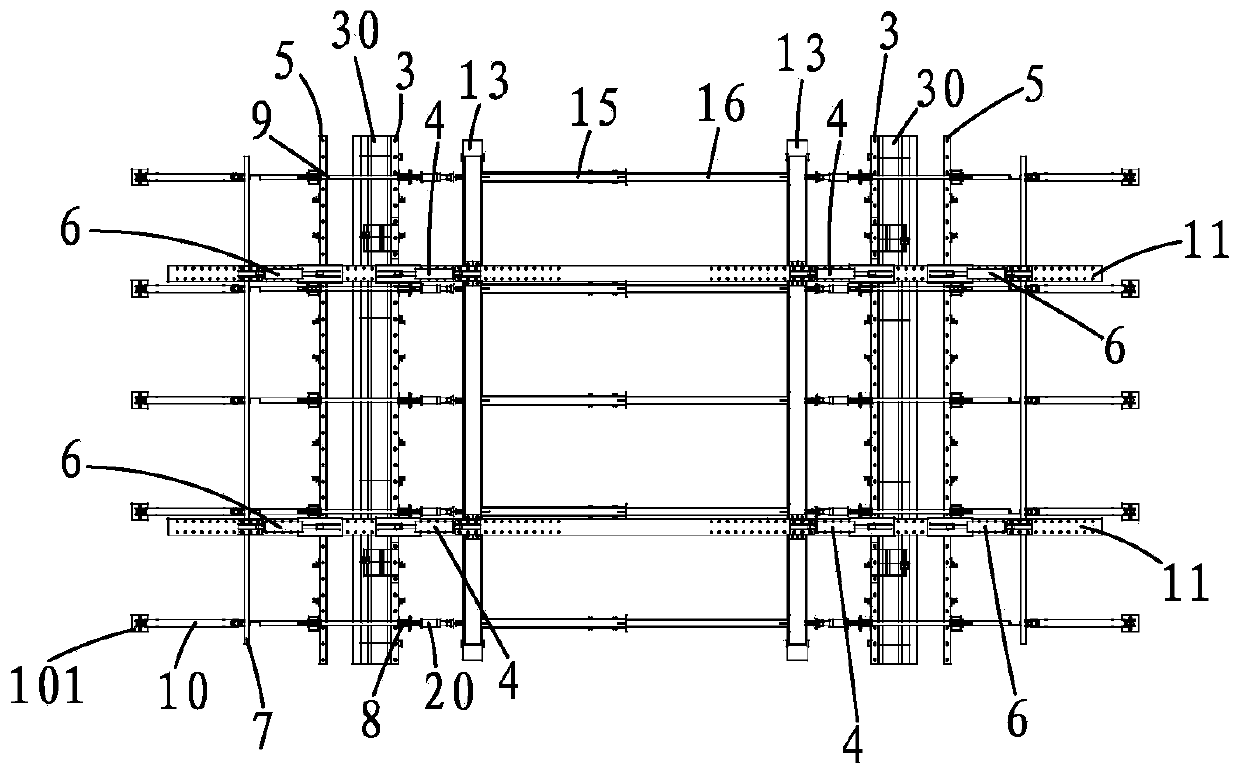

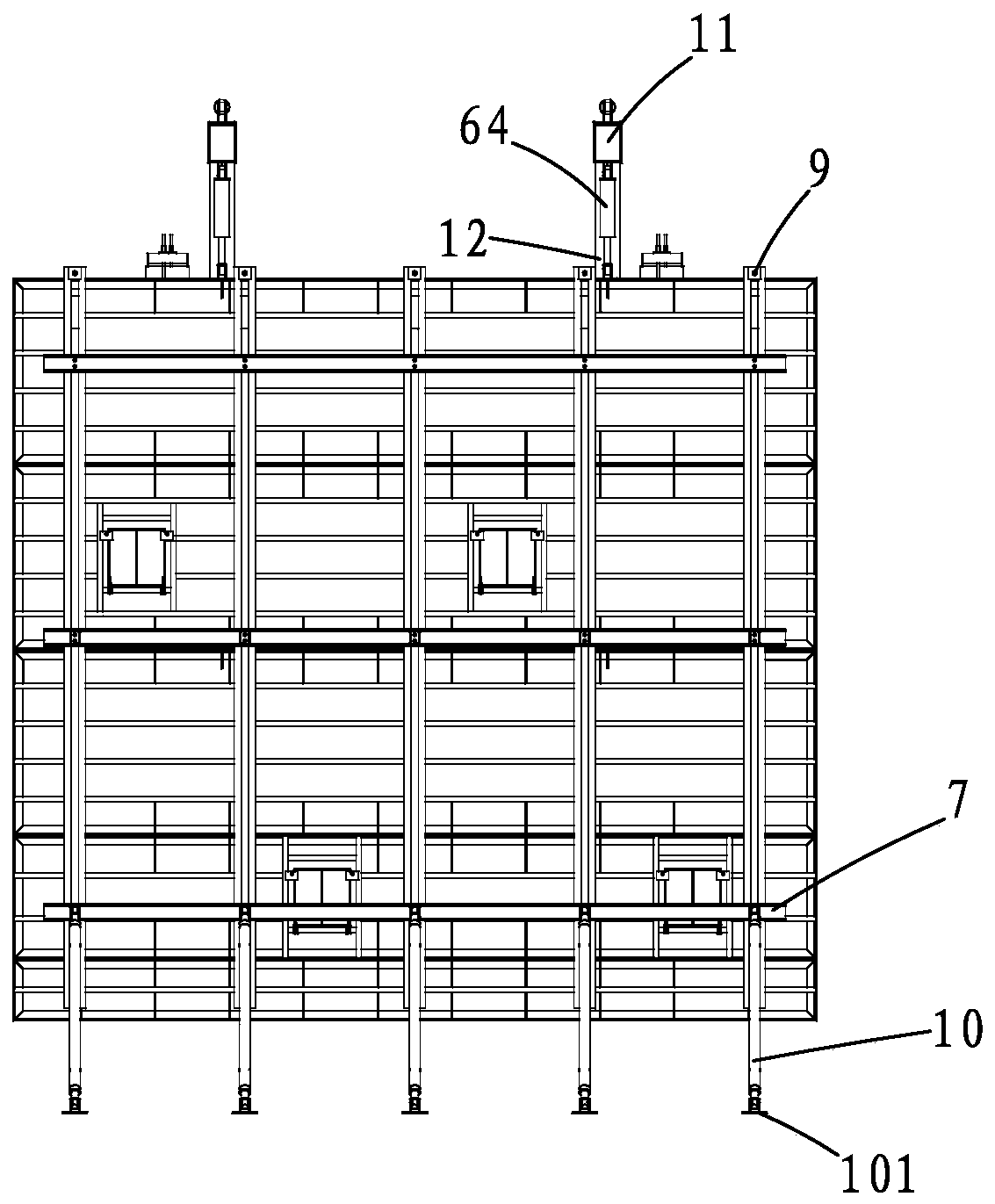

[0038] refer to Figure 1 to Figure 14, a culvert trolley, comprising a portal frame 1, a ground beam walking device 2, an inner mold panel 3, an inner mold movement adjustment device 4, an outer mold panel 5, and an outer mold movement adjustment device 6, and the portal frame 1 includes a template sliding Beam 11, small column 12, upper longitudinal beam 13, large column 14, the ground beam walking device 2 includes ground beam bracket 21 and traveling wheel 22; the upper end of the template sliding beam 11 is fixedly connected with the small column 12, The lower end of the small column 12 is fixedly connected to the upper longitudinal beam 13, and the upper longitudinal beam 13 is also fixedly connected to the upper end of the large column 14, and the lower end of the large column 14 is fixed to the ground beam bracket 21 connected, the traveling wheels 22 are rotatably connected to the ground beam support 21 . The door frame 1 is the main load-bearing component of the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com