Full circle once lining segregation type nose girder module bench and its construction method

A separate, guide beam technology, applied in wellbore lining, tunnel lining, earth-moving drilling, etc., can solve the problems of difficult cleaning of formwork trolleys, small operating space and high cost, and achieve fast disassembly and assembly speed, operating space is wide, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

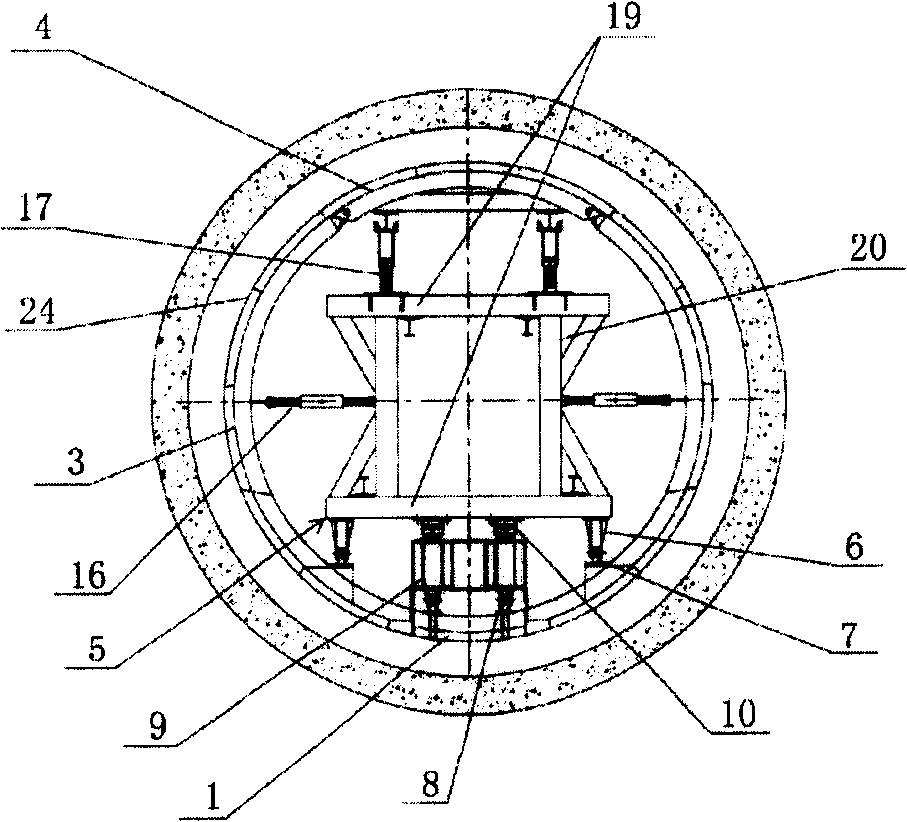

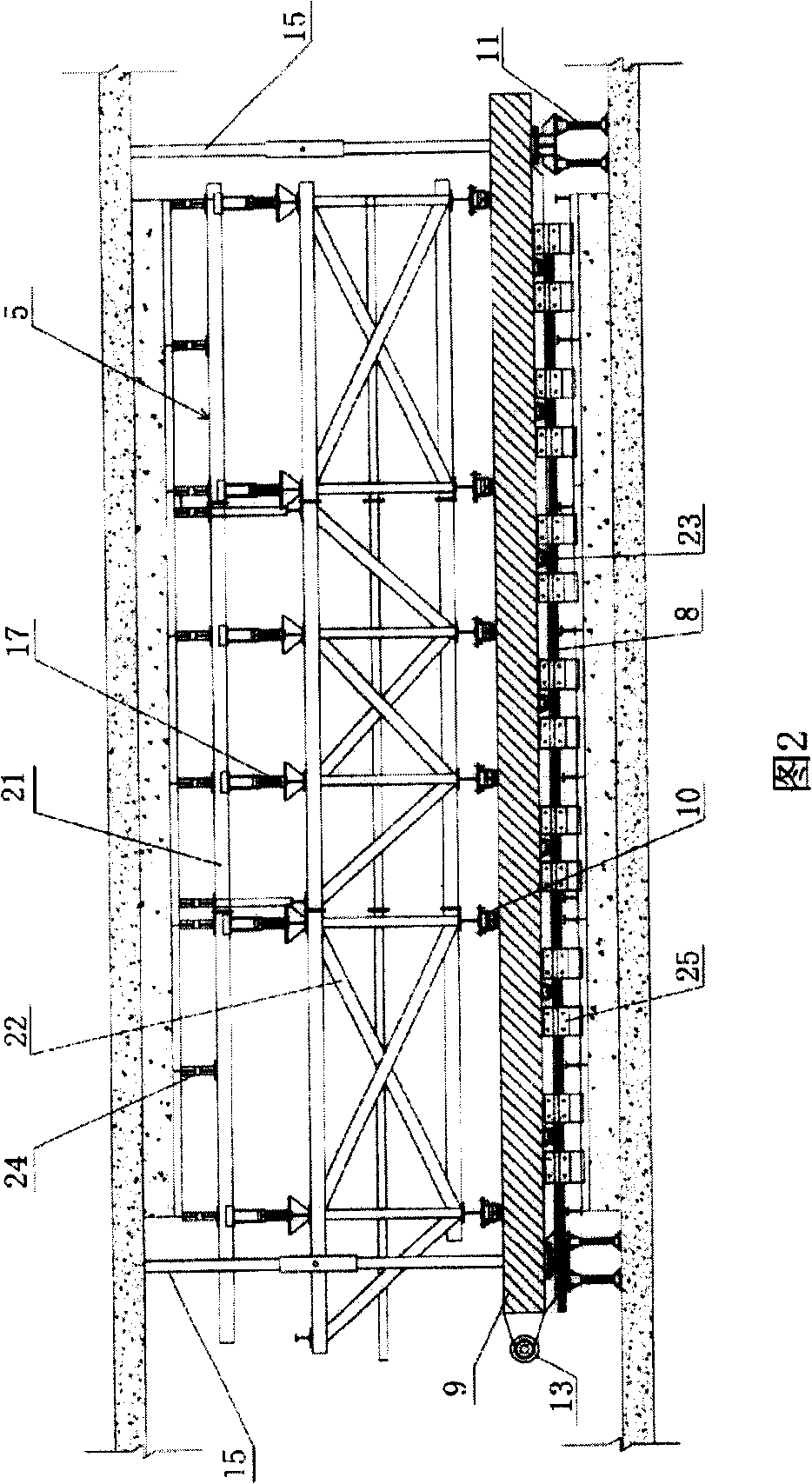

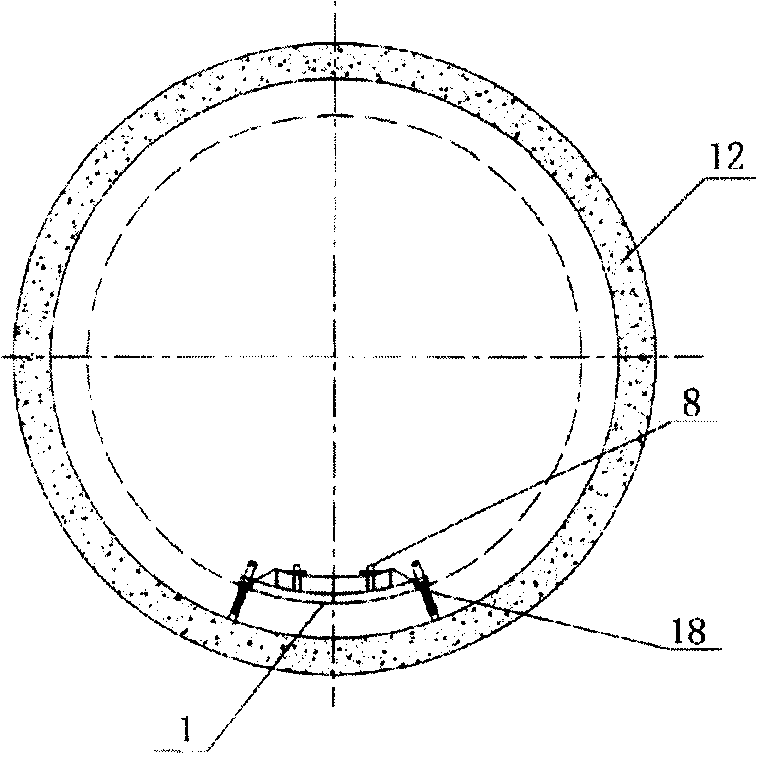

[0047] see figure 1 , Figure 2, this full-circle primary lining separated guide beam formwork platform includes a formwork, a platform and a supporting mechanism between the two. The annular backing beam 24 is connected to the inside of the formwork, and a top mold support screw disk 17 , a side mold support screw 16 and a bottom mold support screw 18 are supported between the annular back beam 24 and the stand 5 .

[0048] Its formwork includes bottom formwork 1, bottom side formwork 2, side formwork 3 and top formwork 4 which are bolted into a cylindrical shape. Example of formwork size: formwork diameter is 4.01m; 1429×864mm, 864mm sides are arc-shaped ends; panel thickness It is a 4mm steel plate, the back rib is a 4mm steel plate, the circumferential spacing of the back ribs is 216mm, and the longitudinal spacing of the back ribs is 286mm. The bottom template adopts; 1429×1372mm, and the side of 1372mm is a curved end. The bottom template is processed with exhaust holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com