Suspended combined hydraulic beaming device

A suspended, hydraulic technology, applied in mining equipment, earth-moving mining, pillars/supports, etc., can solve the problems of adding manual handling consoles, can not reduce the labor intensity of employees, increase the labor intensity of employees, etc., and achieve light weight. , easy operation, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0026] A preferred embodiment is given below:

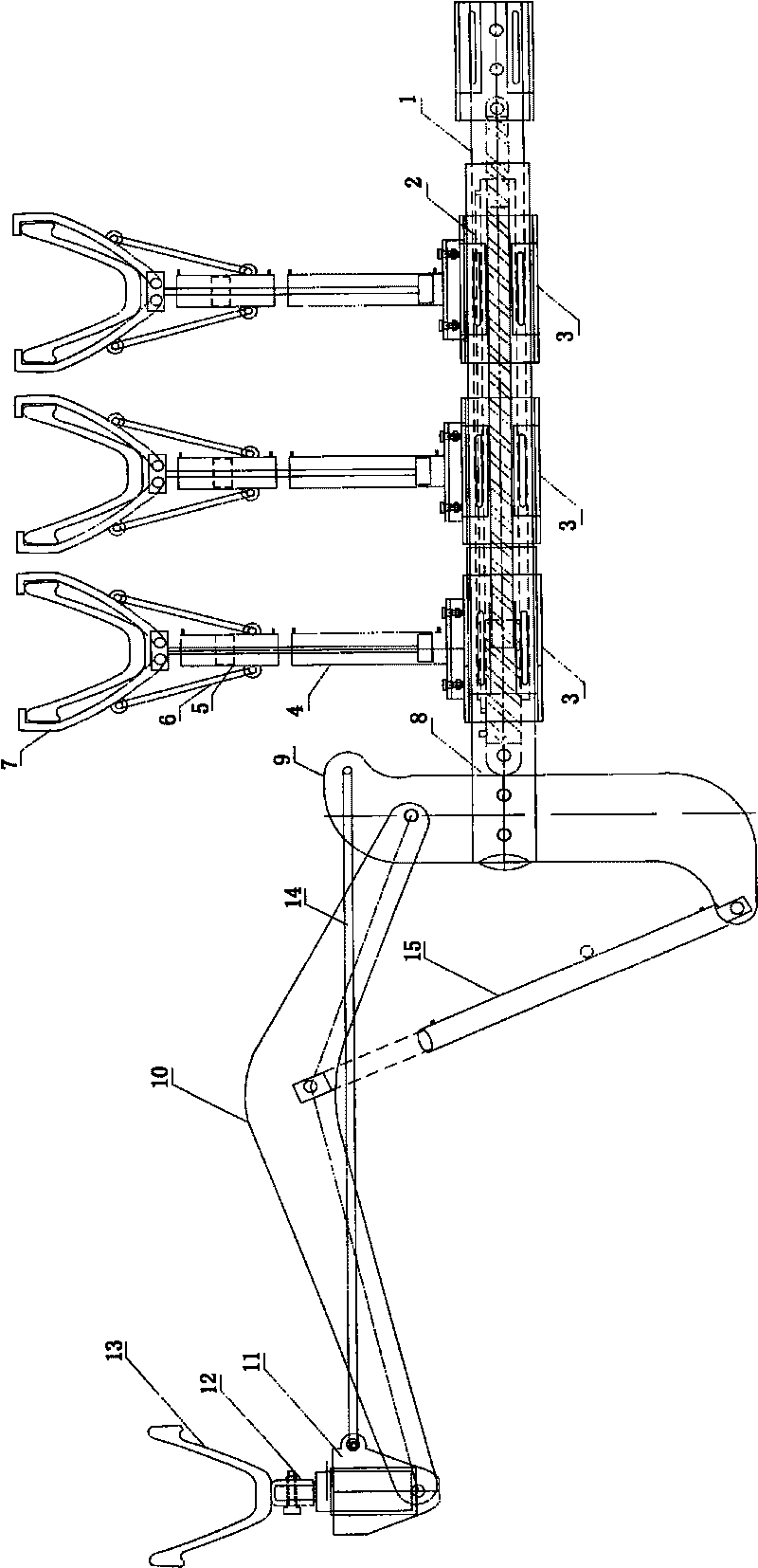

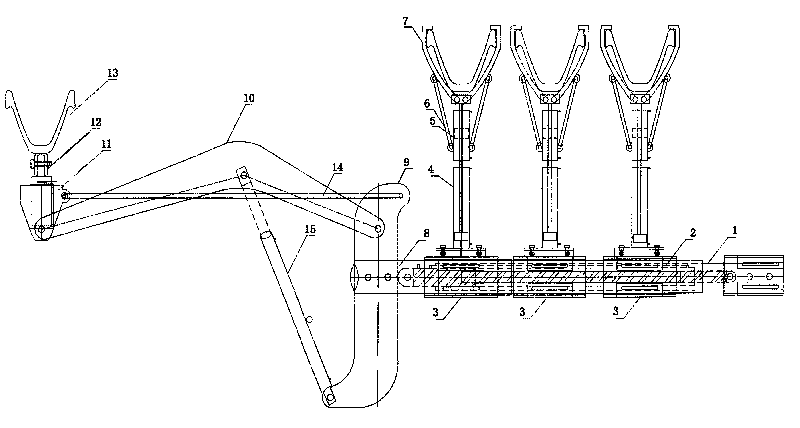

[0027] A suspended combined hydraulic beam upper device, comprising a main beam 1, on which a sub-beam 2 is arranged, and on the main beam 1, the upper part of the main beam bracket 3 is connected to the lifting cylinder 4 through a hanging hand grasping lifting cylinder 4. Hanging hand grasping oil cylinder 5, the hanging hand grasping oil cylinder 4 is connected to hanging hand grasping 7 through hanging hand grasping connecting rod 6, and the main beam supporting cover 3 is also connected with the main beam walking and Hanging arm walking oil cylinder 8; the end of the main beam 1 is provided with a joist arm seat 9, and the joist arm seat 9 is connected with a joist mechanism.

[0028] The joist mechanism comprises a joist arm 10 hinged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com