Double-beam walking trolley

A technology of walking trolley and square frame, which is applied in the direction of traveling mechanism, load hanging components, transportation and packaging, etc., which can solve the problems of uneven force on the double-beam walking trolley and affect the service life, so as to avoid uneven force, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

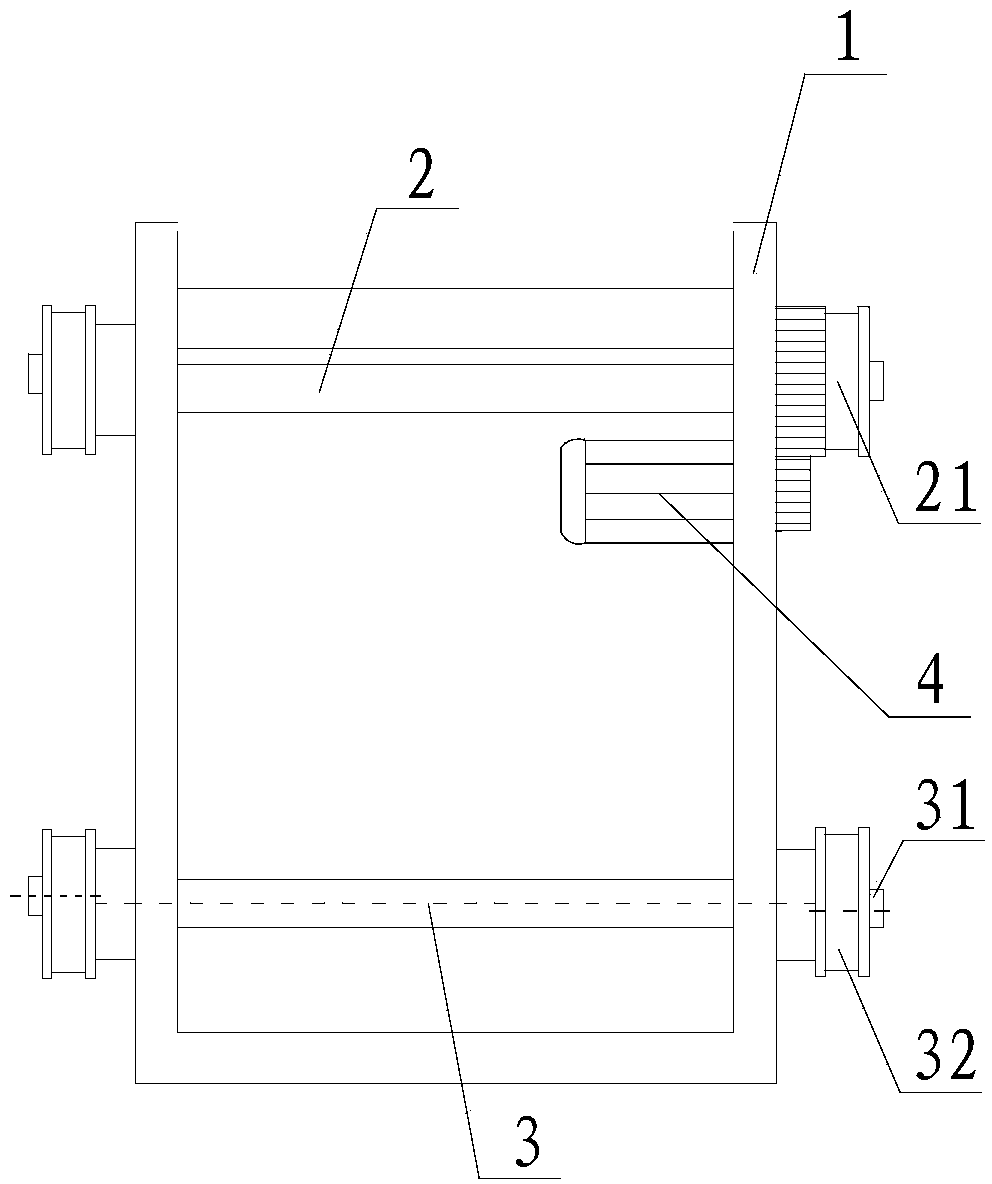

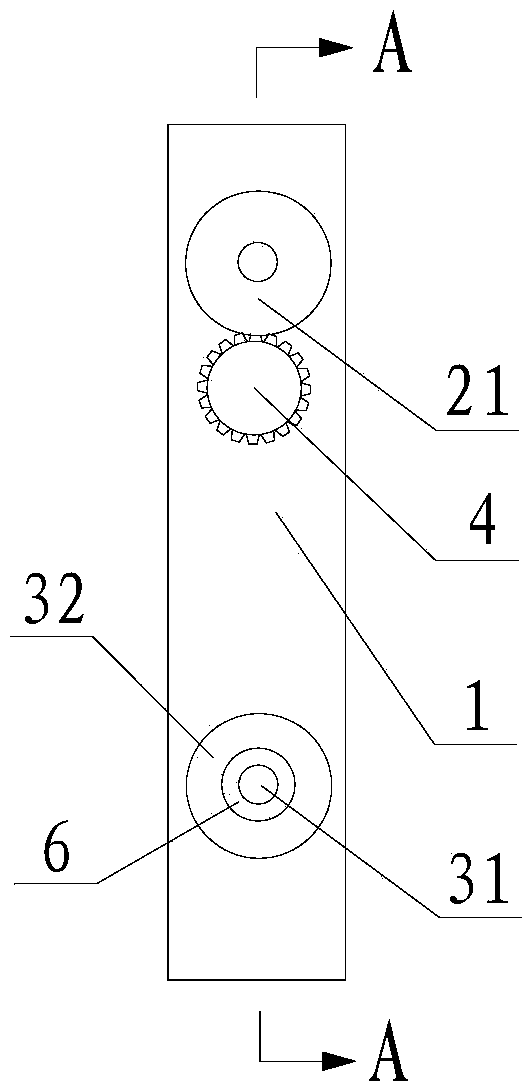

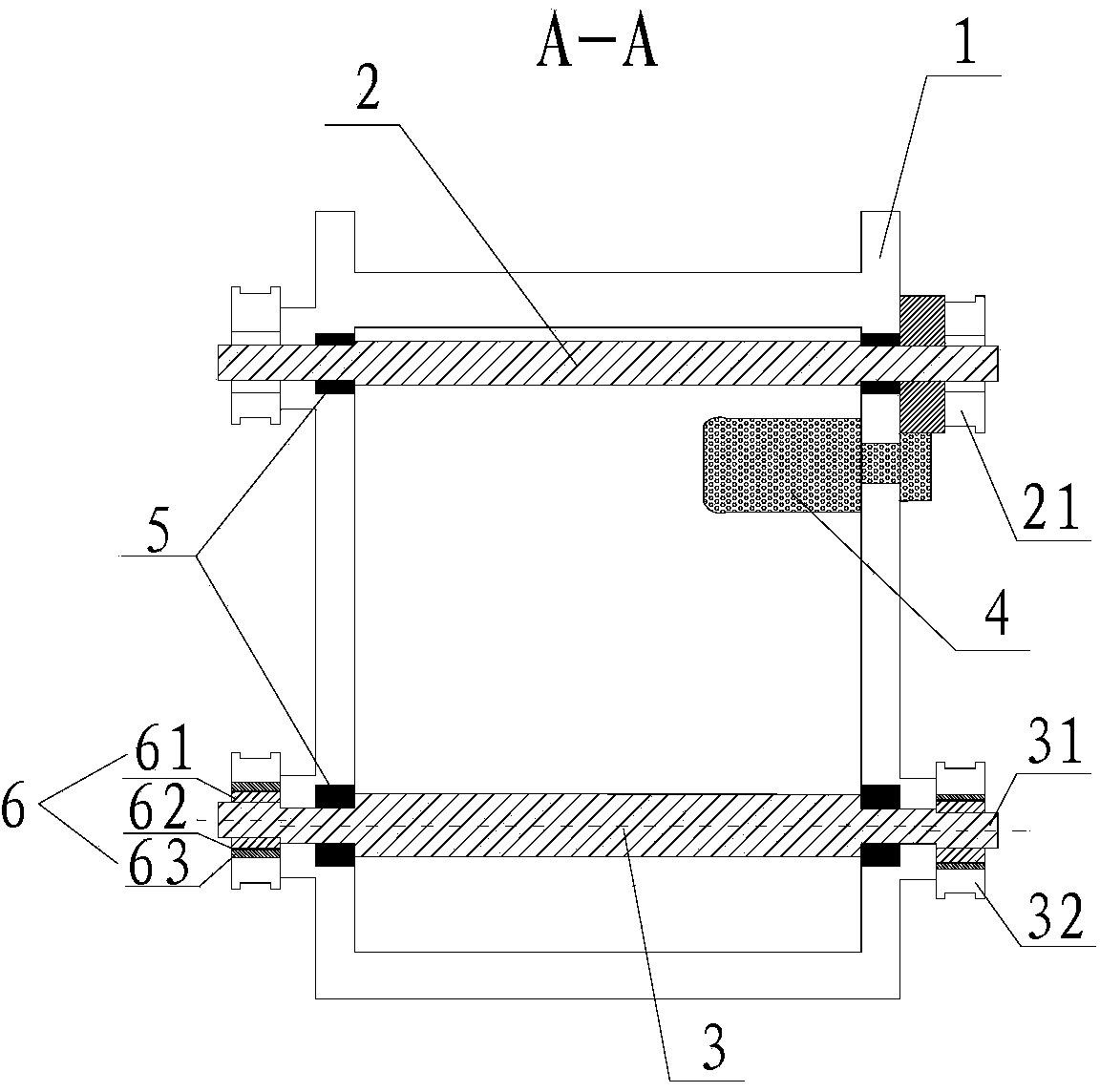

[0016] Such as Figures 1 to 3 The shown double-beam walking trolley mainly includes a square frame body 1, a driving shaft 2, a driving wheel 21, a driven shaft 3, a driven wheel 32, and a motor 4.

[0017] Wherein, the driving shaft 2 and the driven shaft 3 are rotatably installed in the square frame body 1, they are parallel to each other and in the same horizontal plane; the driving wheel 21 is fixed at both ends of the driving shaft 2 and is located outside the square frame body 1; The motor 4 is installed in the square frame body 1 and meshed with one of the driving wheels 21 to provide power; the two ends of the driven shaft 3 are integrally fixed with cylindrical protrusions 31, and the cylindrical protrusions 31 are located in the square frame body 1 The outer side is equipped with a driven wheel 32, and the driven wheel 32 can ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com