Scraping plate material taking machine

A reclaimer and scraper technology, applied in conveyors, transportation and packaging, etc., can solve the problems of low reclaiming efficiency, poor scraper hardness, easy leakage of materials, etc., reducing welding workload and long service life. , Improve the effect of product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

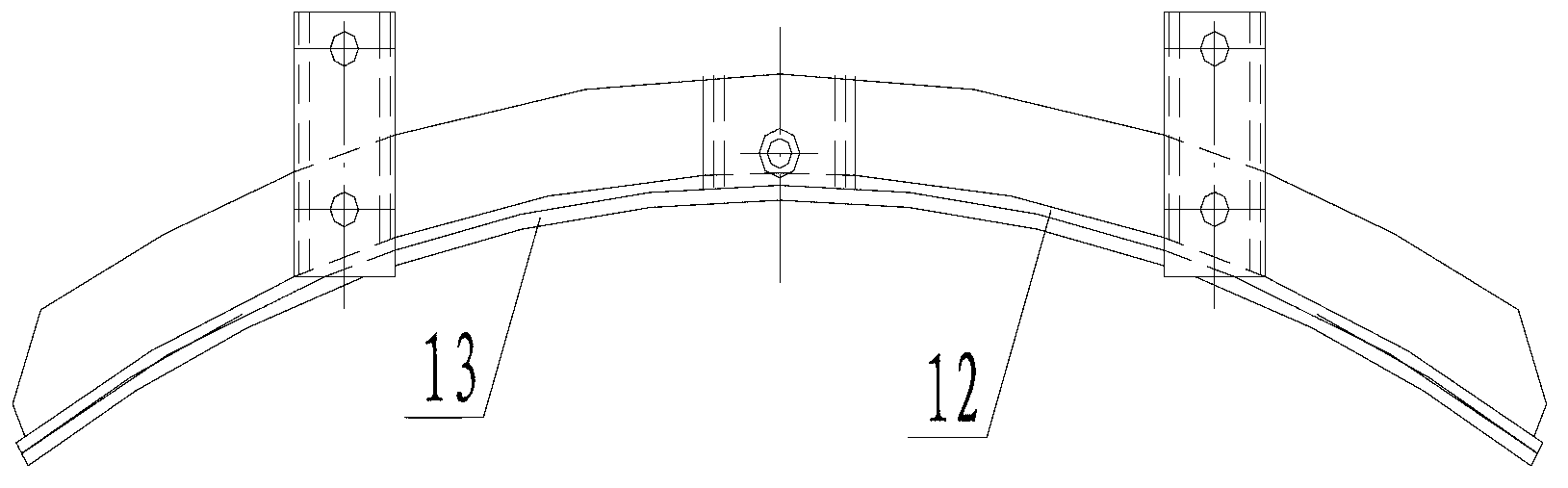

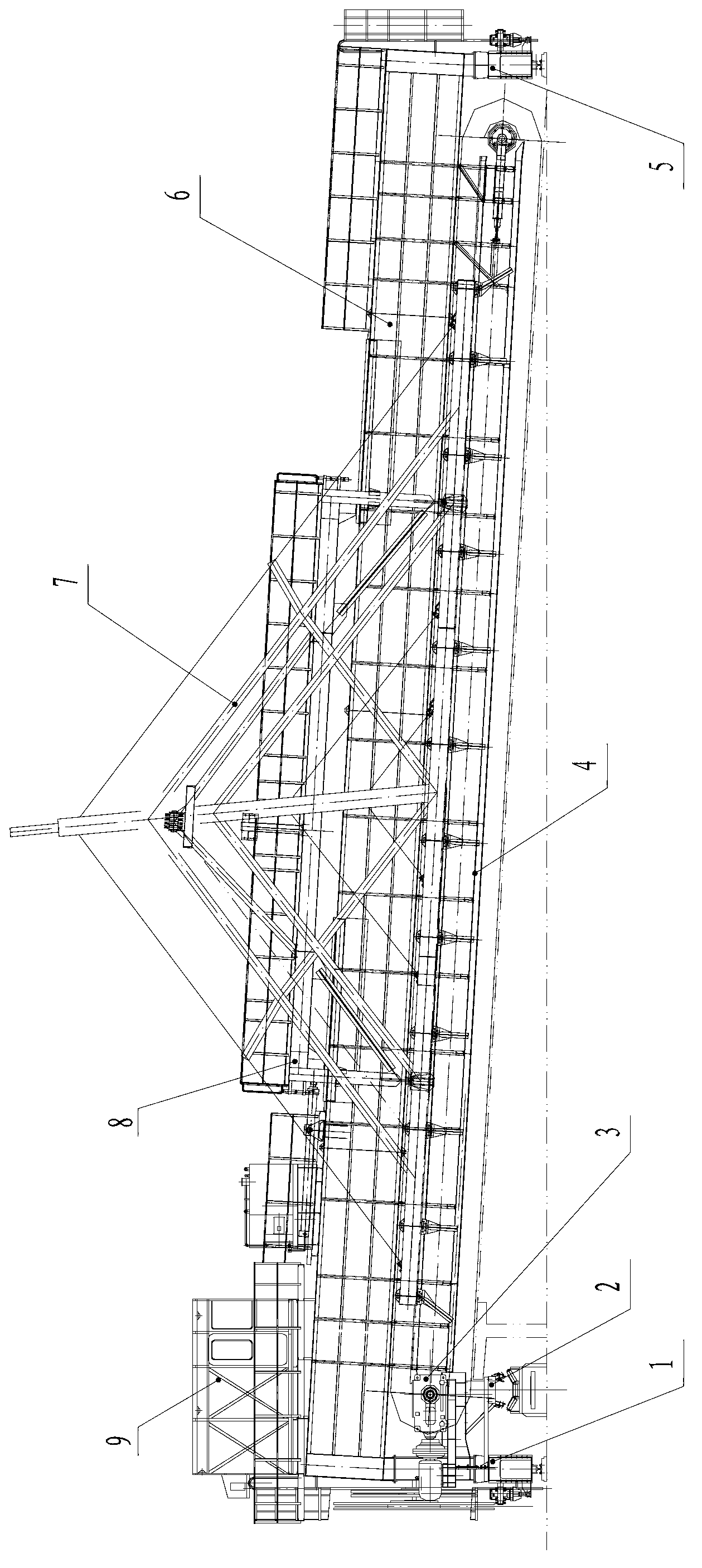

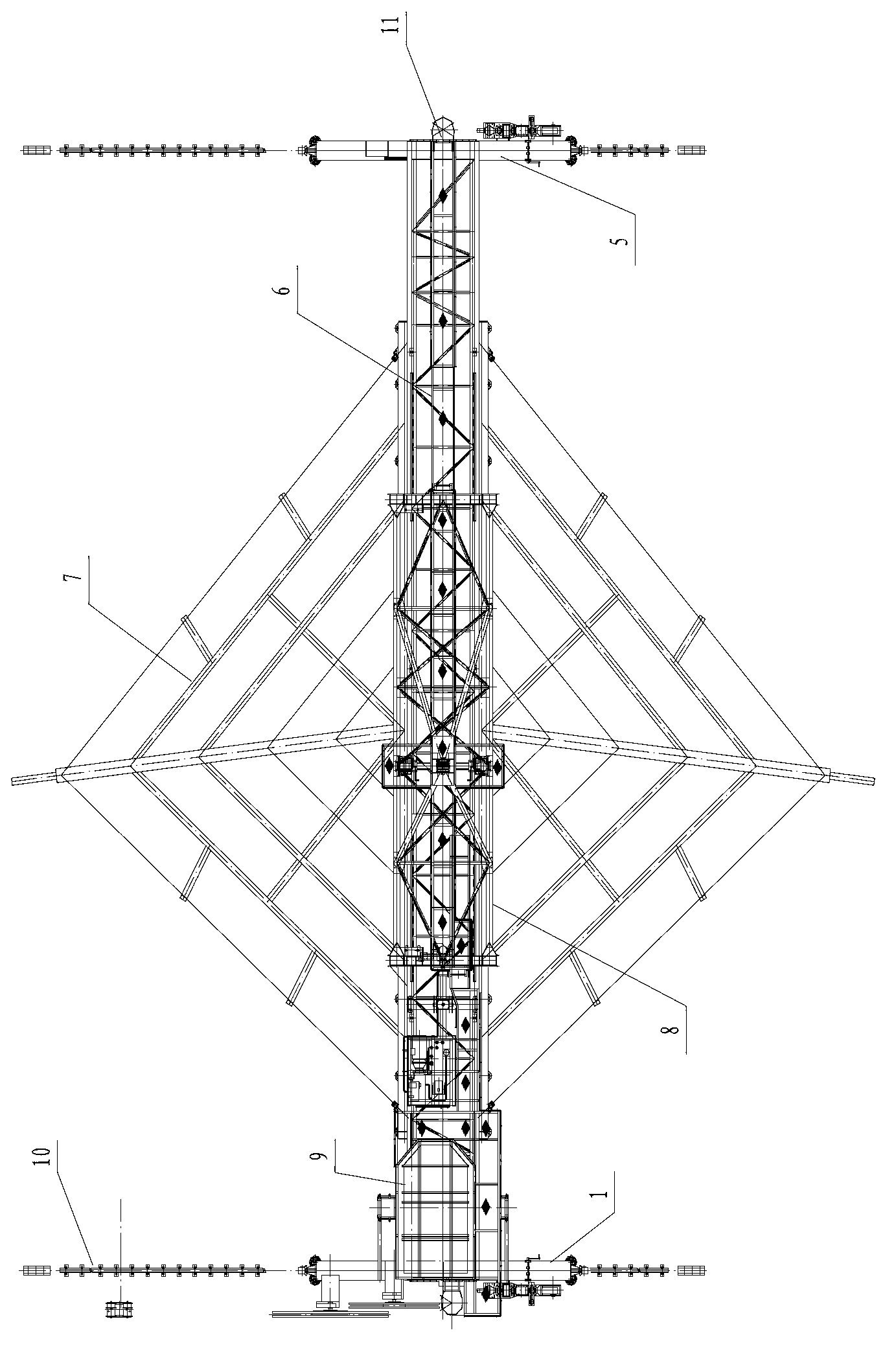

[0022] Combine below Figure 1 to Figure 4 Make specific instructions for scraper reclaimers.

[0023] The scraper reclaimer includes a track system 10, a head wheel end beam traveling mechanism 1, a tail wheel end beam traveling mechanism 5, a main beam 6, a rake frame 7, a transmission mechanism 3, a scraper chain 4, a mobile trolley 8 and a discharge hopper 2, The lower parts of the two ends of the main beam 6 are respectively connected with the head wheel end beam running mechanism 1 and the tail wheel end beam running mechanism 5, and the deviation correcting device 11 is installed between the tail wheel end beam running mechanism 5 and the main beam 6, and the head wheel end beam running mechanism 1 and the tail wheel end beam traveling mechanism 5 are all arranged on the track system 10, and can move on the track system 10, the side of the main beam 6 is provided with a rake frame 7, the main beam 6 is provided with a mobile trolley 8, and the main beam 6 The lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com