Dismounting and mounting tool for hoist crane lifting motor

A hoist crane and tool technology, applied in manufacturing tools, hand-held tools, hoisting devices, etc., can solve the problems of motor deviation, time-consuming and labor-intensive, and inability to guarantee the level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

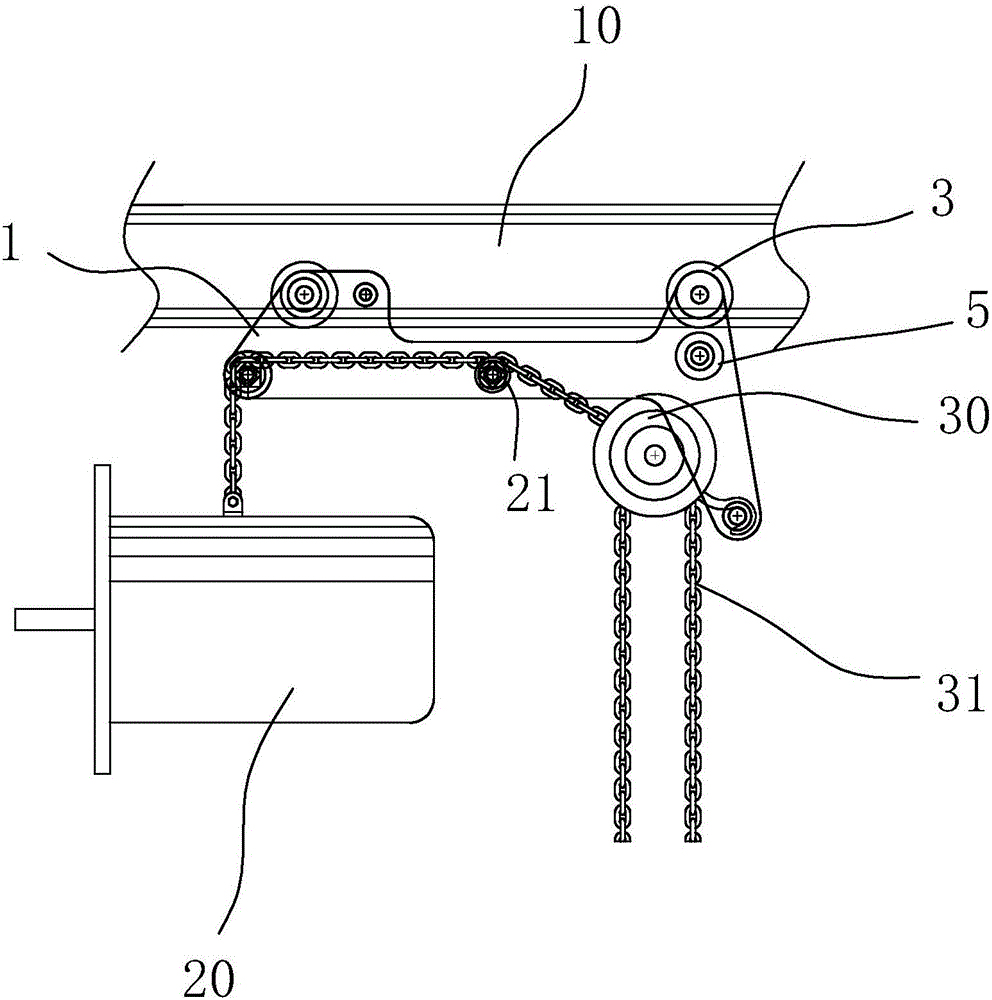

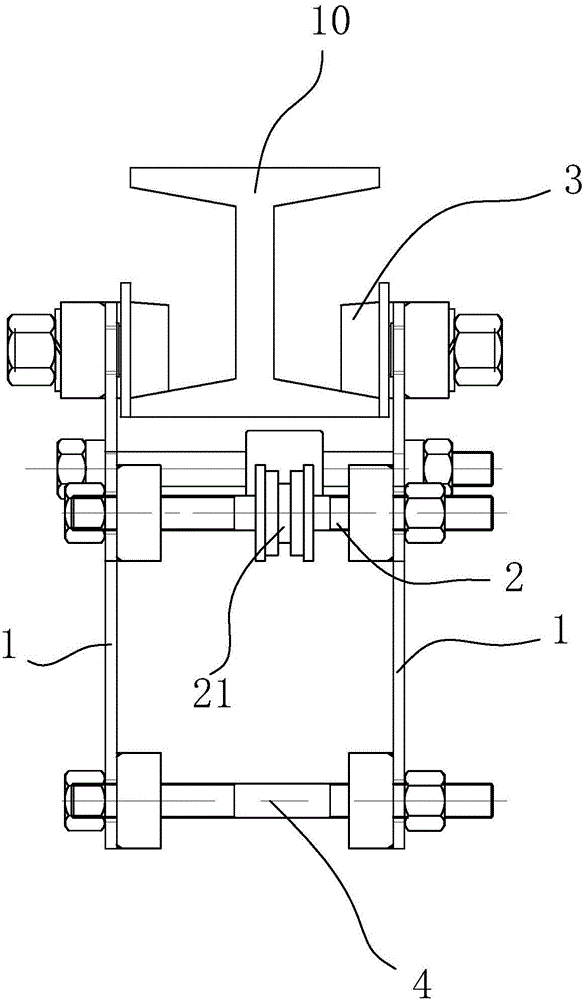

[0016] refer to figure 1 , figure 2 , the present invention is a lifting motor dismounting tool for a hoist, comprising two symmetrically arranged outer plates 1 and at least two guide shafts 2 connected between the two outer plates 1, the middle of each guide shaft 2 is provided with a guide for erecting a chain 31 Wheels 21 are respectively provided with two direction wheels 3 above the inner sides of the two outer plates 1, the axes of the four direction wheels 3 are located on the same horizontal plane, the axes of the two guide shafts 2 are located on the same horizontal plane, and are located below the inner sides of the two outer plates 1. A positioning rod 4 for fixing the hoist crane 30 is also provided.

[0017] This hoist hoist lifting motor disassembly tool can hang the disassembly and assembly workpiece on the upper flat beam walking track 10 as a whole through the four direction wheels 3 inside the two outer plates 1 to move laterally, and the hoist crane 30 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com