Bridge cantilevered sidewalk slab formwork system and construction method

A sidewalk slab and cantilever technology, which is used in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of uneven length of sidewalk slabs, labor and time consuming construction, and dislocation of formwork joints. , to achieve the effect of simple and easy construction method, reduce construction cost and improve straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

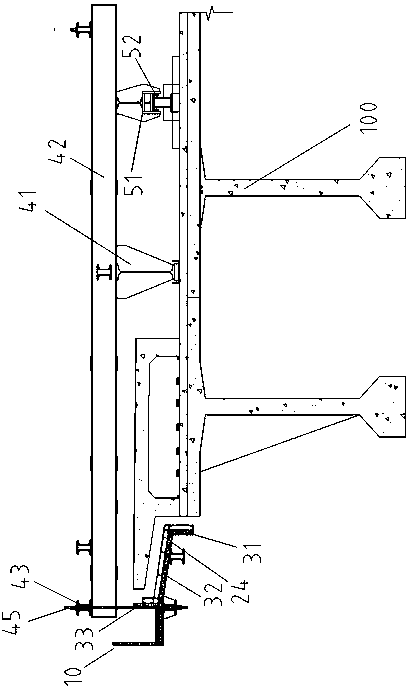

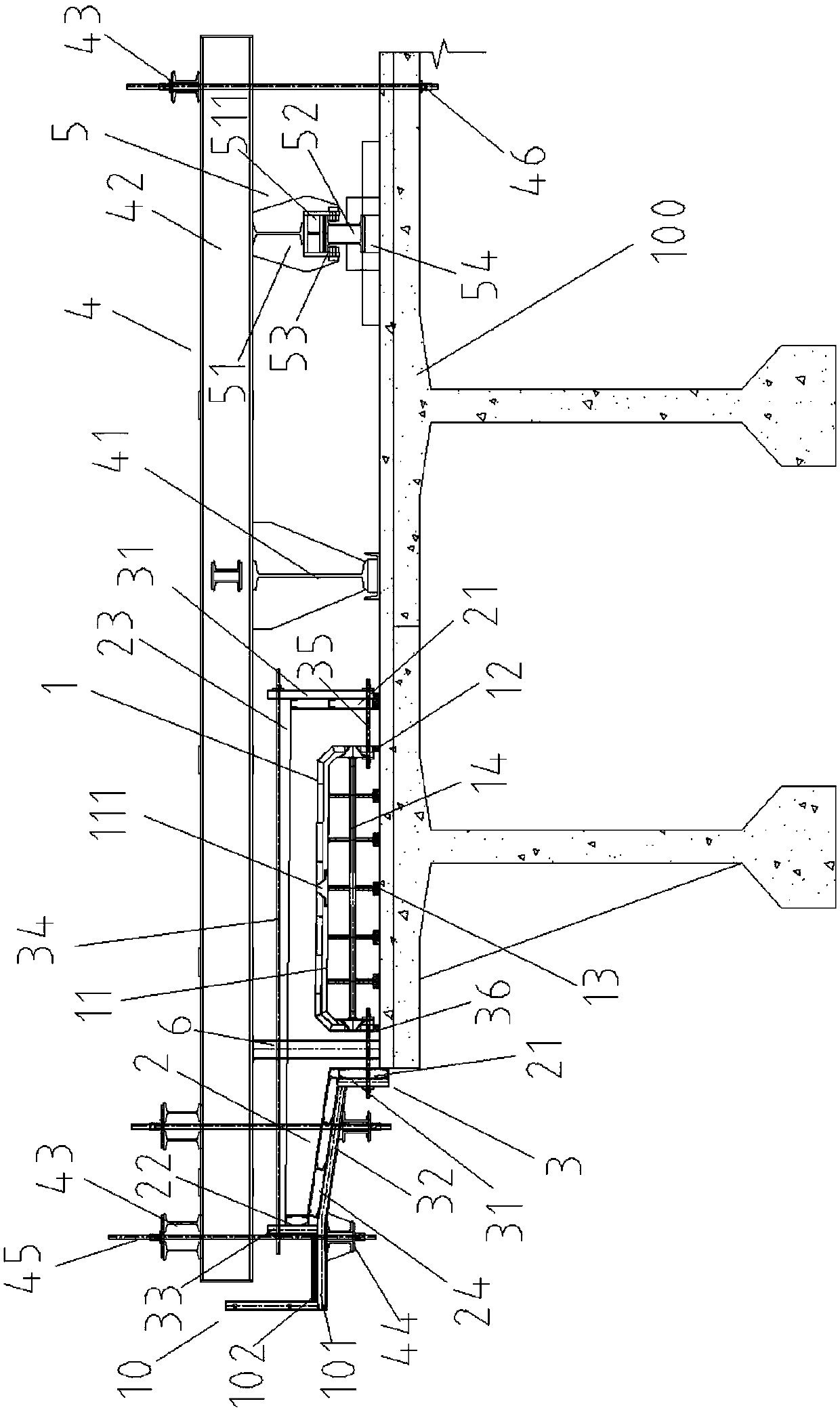

[0028] Such as figure 1 As shown, the bridge cantilevered walkway slab formwork system of the present embodiment includes an arched combined inner mold 1 supported on the T-shaped beam combination 100 and a cantilevered combined mold 2 extending out of the T-shaped beam combined body, and the arched combined inner mold 1 includes a horizontal upper mold 11 connected as one and vertical side molds 12 on both sides. The middle part of the horizontal upper mold 11 and the middle part of the vertical side mold 12 are respectively provided with a figure-eight inner mold 111 to facilitate mold removal. The inner side of the arched combined inner mold 1 is also provided with five side-by-side vertical support frames 13, the upper and lower ends of the vertical support frames 13 are respectively supported between the inner side of the horizontal upper mold 11 and the T-shaped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com