Automatic pharmaceutical glass packaging and integrating system

An automatic packaging and integrated system technology, applied in the field of machinery and equipment, can solve problems such as difficulty in adapting to the development of large-scale production, difficulty in guaranteeing product quality, low production efficiency, etc. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

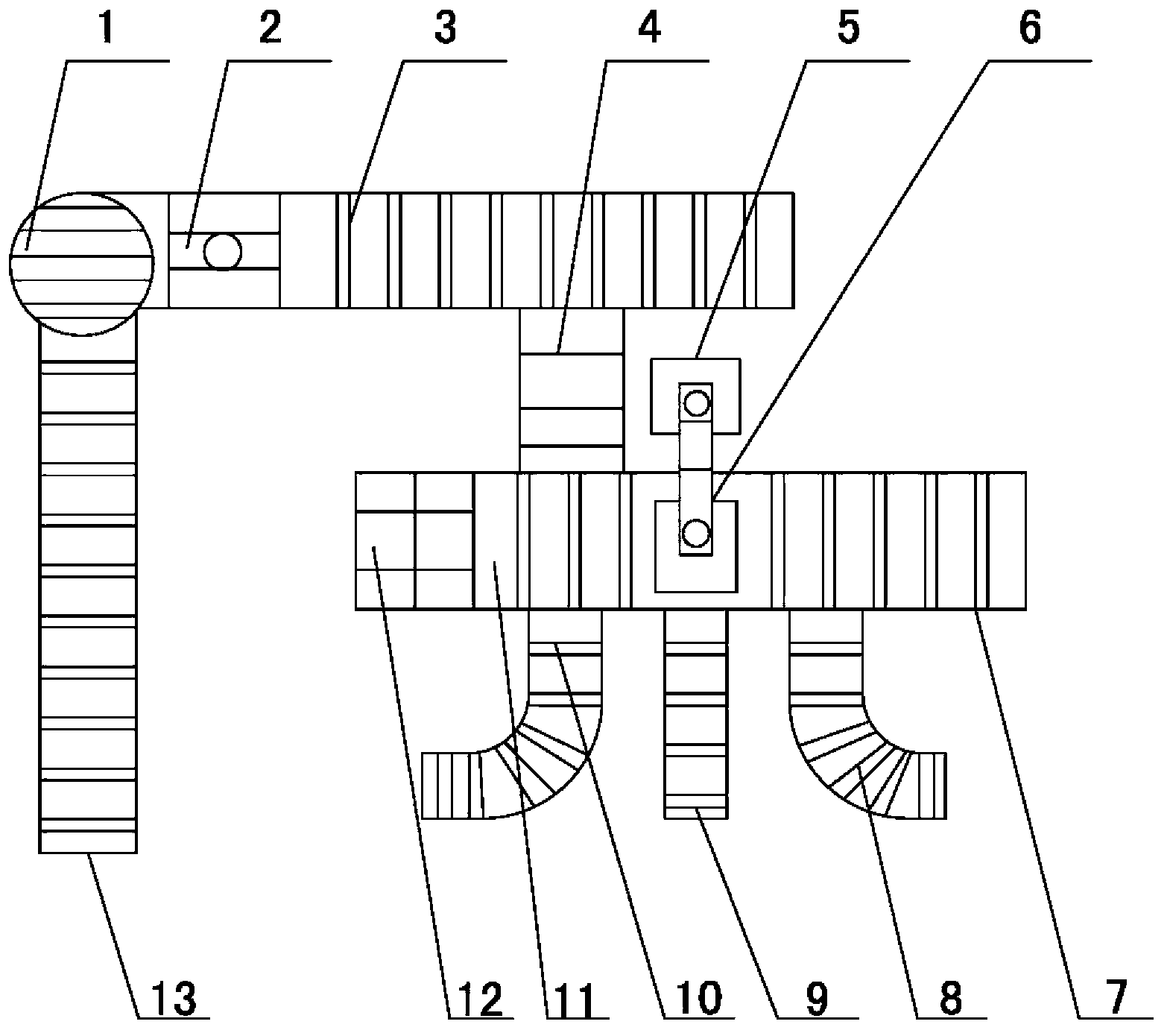

[0019] Such as figure 1 As shown, the pharmaceutical glass automatic packaging integrated system includes a transfer robot 6 and a pallet conveyor line 11 distributed around the transfer robot 6, a backing plate conveyor line 7, a cover plate conveyor line 10, a grabbing line 8, and a heavy pallet conveyor line 3. Palletizing area 4, the pallet conveying line 11 is connected to the stacker 12, the grabbing line 8 is connected to the hot pack conveying line 9, the heavy-duty pallet conveying line 3 is equipped with a fully automatic rotary packing machine 2, and the mechanical arm of the transfer robot 6 The compound manipulator 5 is installed on the top, and the compound manipulator 5 is connected to the PLC control system. The left side of the heavy-duty pallet conveying line 3 is equipped with a recovery conveying line 13, and the recovering conveying line 13 and the heav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com