Vehicle battery replacement station

A technology for power exchange stations and automobiles, which is applied to vehicle maintenance, vehicle components, electric power devices, etc., can solve the problems of unexpandable or difficult expansion of charging racks, poor applicability of charging and exchanging stations, and inability to adjust flexibly, so as to save electricity and exchange electricity. Time, flexible and convenient use, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

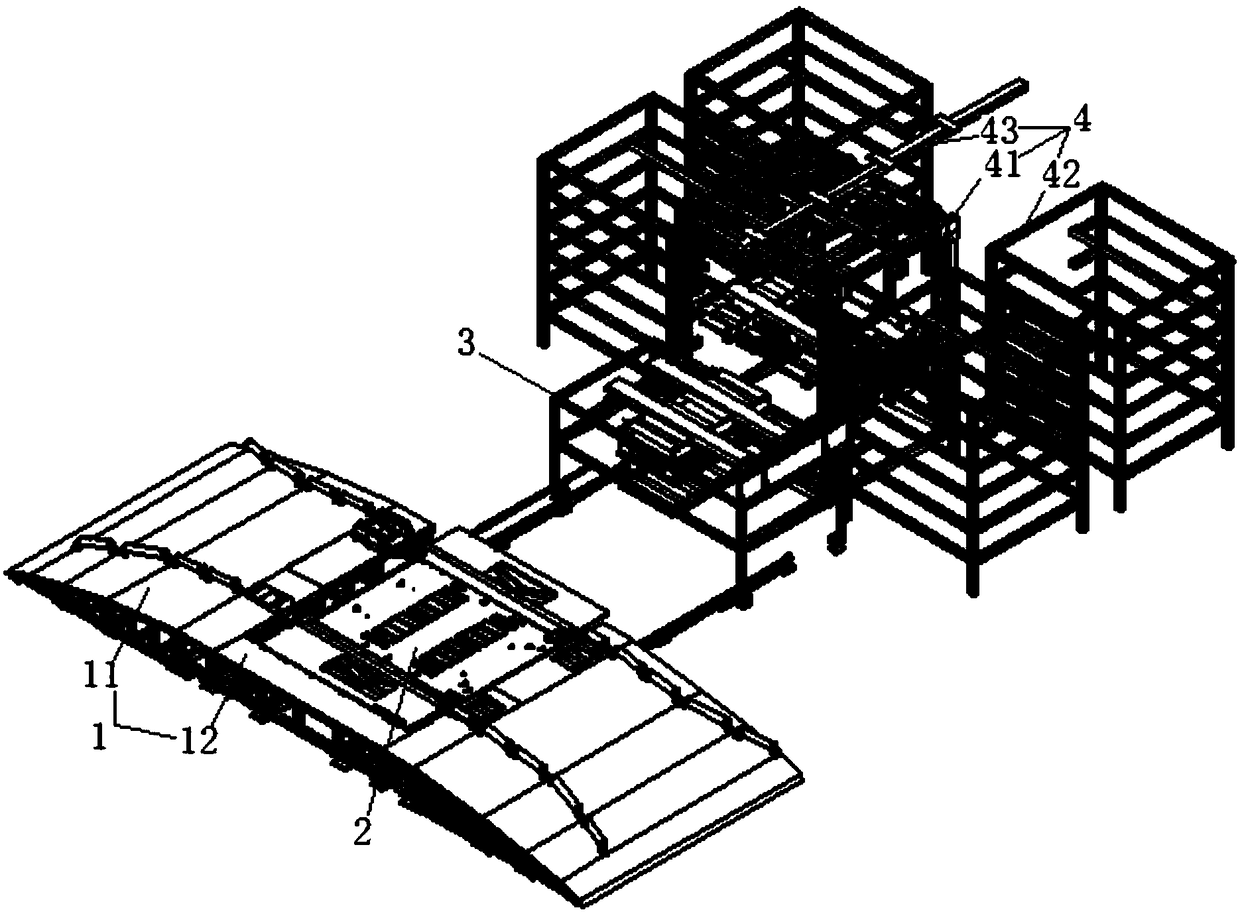

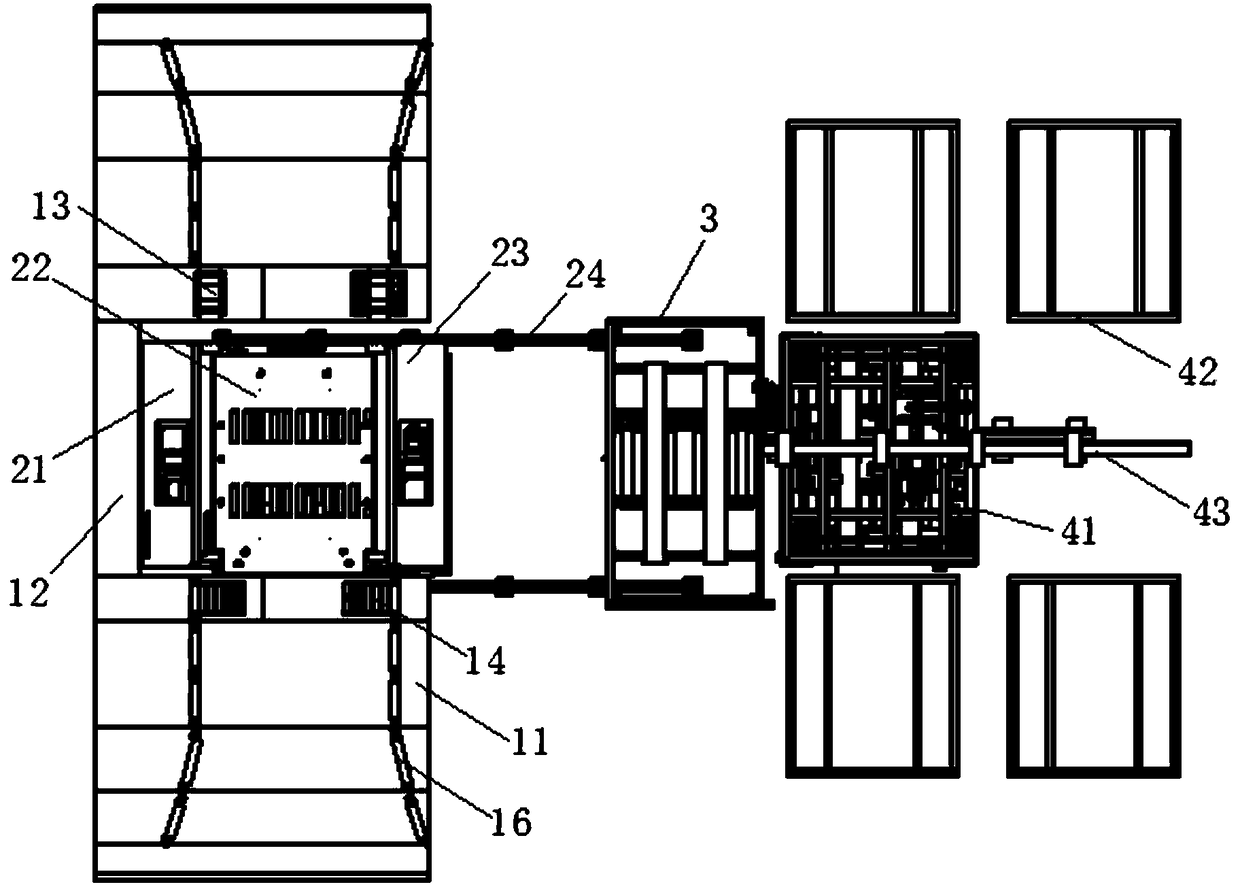

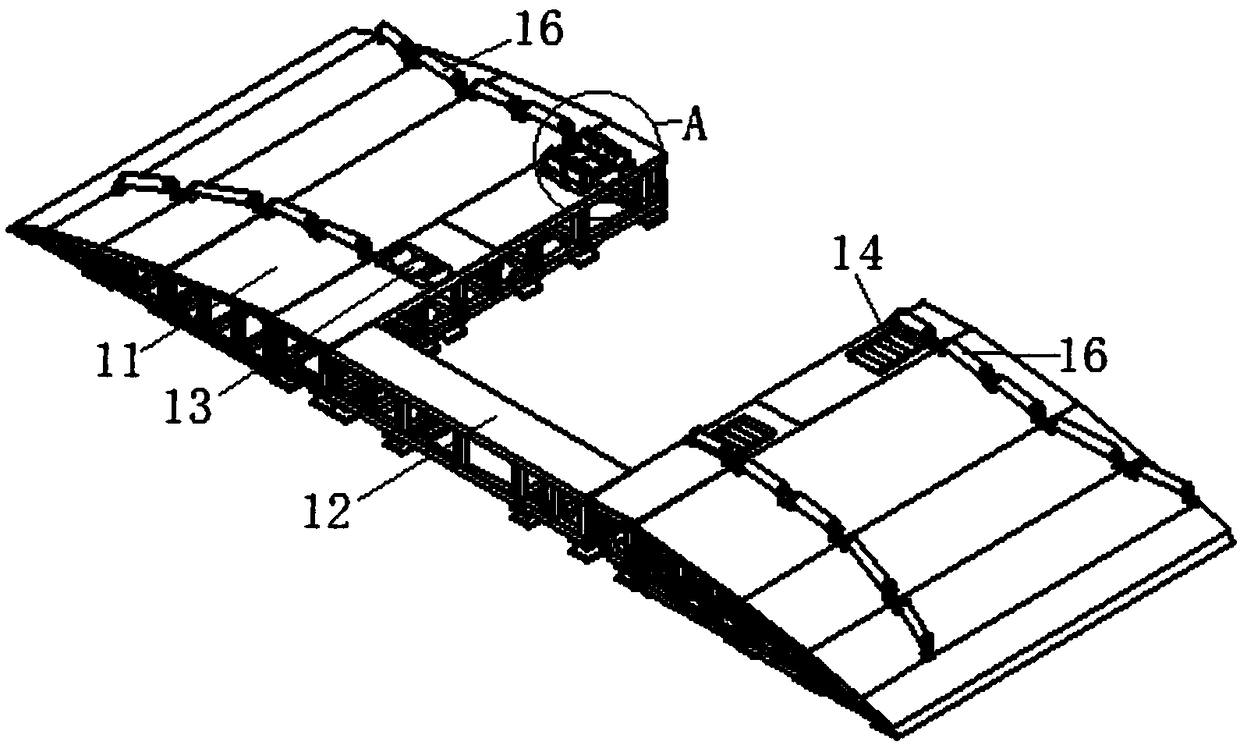

[0035] Embodiment: A car replacement station, including a positioning platform 1, a battery replacement mechanism 2, a battery buffer mechanism 3, and an expansion charging compartment 4; a positioning platform 1 is provided on one side of the battery buffer mechanism 3; the positioning platform 1 The middle part is provided with a power exchange mechanism 2; the other side of the battery cache mechanism 3 is provided with an expansion-type charging bin 4; the expansion-type charging bin 4 includes a lifting connection mechanism 41 and a charging stand 42; the lifting connection Charging racks 42 are arranged on both sides of the mechanism 41, and the distribution direction of the charging racks 42 is the same as the walking direction of the lifting connection mechanism 41; Take out the fully-charged battery in the battery cache mechanism 3 and transport it back to the car; the lifting connection mechanism 41 transports the deficient battery in the battery cache mechanism 3 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com