Programmed control slow-starting high stabilization great current drive device

A high-current drive, slow-start technology, which is applied in photoplate-making process exposure devices, differential amplifiers, DC-coupled DC amplifiers, etc., can solve problems such as low accuracy and large current output fluctuations, and achieve simple production and high current. Stable, simple circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The driving circuit of the present invention will be further described through embodiments below in conjunction with the accompanying drawings.

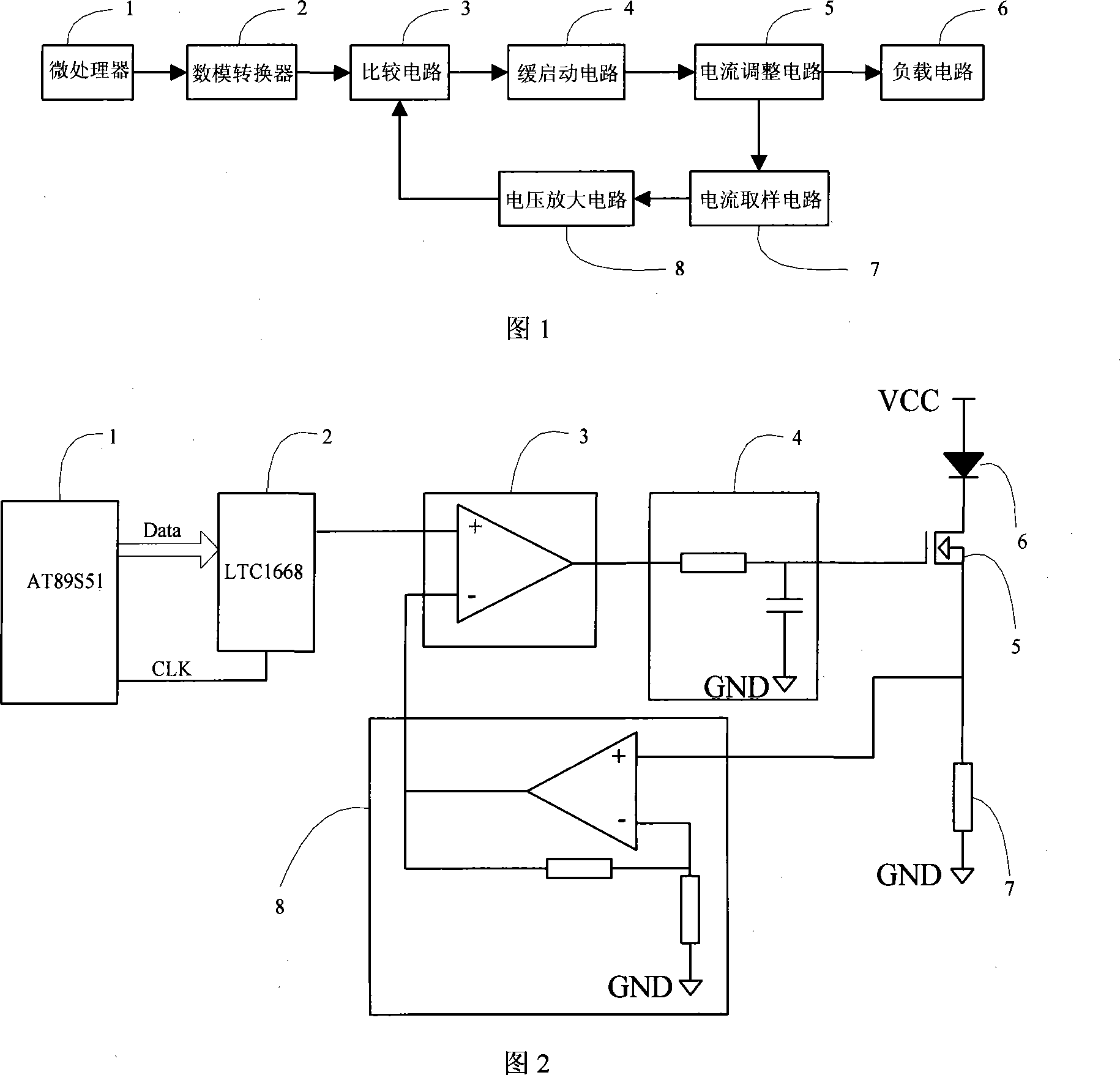

[0018] Figure 1 shows a schematic block diagram of a program-controlled slow-start high-stability high-power LED constant-current drive device. Its structure consists of a microprocessor, a digital-to-analog converter, a comparison circuit, a slow-start circuit, a current adjustment circuit, an LED load circuit, and a voltage amplification circuit. , Composed of current sampling circuit.

[0019] Fig. 2 shows a kind of actual application circuit diagram of program-controlled slow start high stable high current drive device on the high-power LED drive, its structure includes: microprocessor 1, preferably single-chip microcomputer AT89S51, but not limited to this microprocessor; Analog-to-analog converter 2, preferably LTC1668, but not limited to this digital-to-analog converter; dual-channel operational amplifier LM358, respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com