Numerically controlled notching press and method for controlling notching process by using computer program

A technology of notching machine and fuselage, applied in the direction of electrical program control, digital control, etc., can solve the problems of inability to process oblique and straight slot iron core chips, and cannot move tangentially, so as to improve production efficiency, realize program control, and apply wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

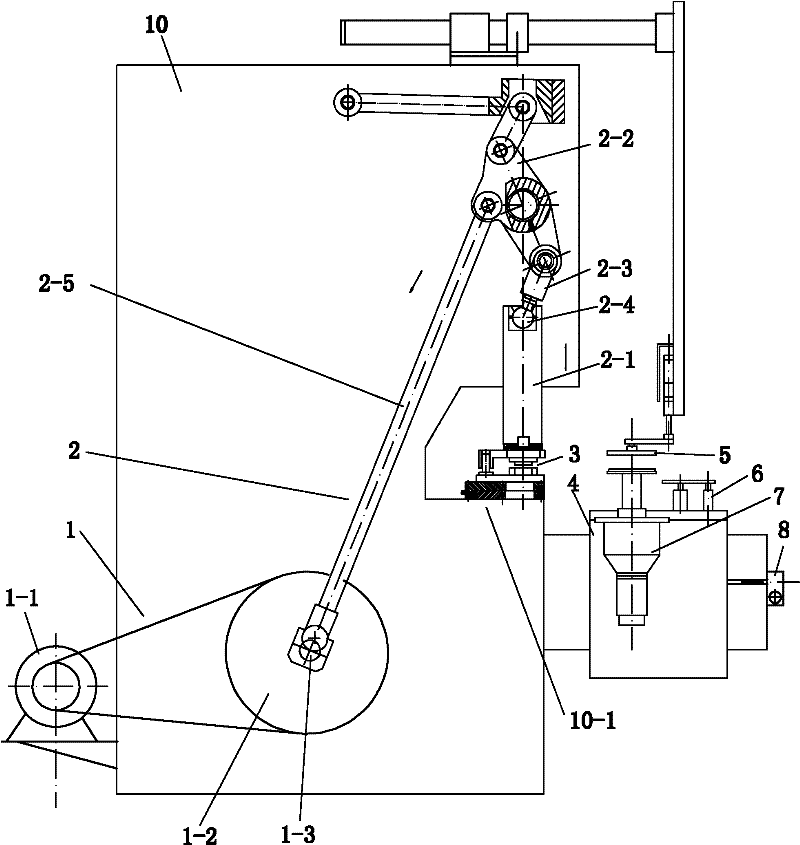

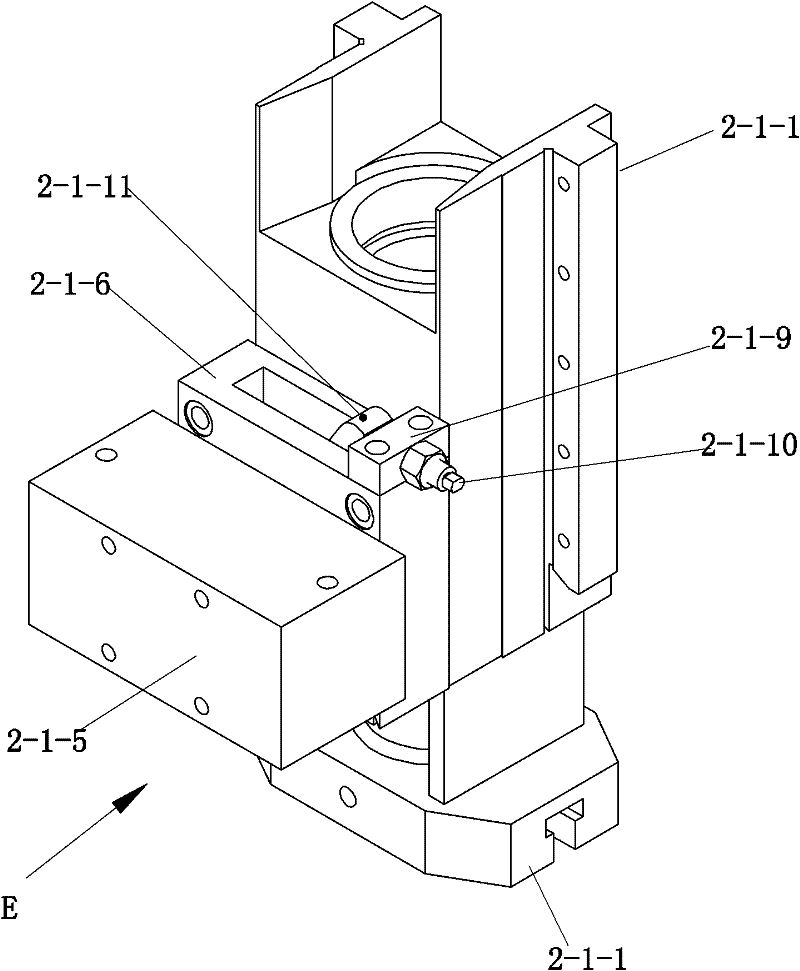

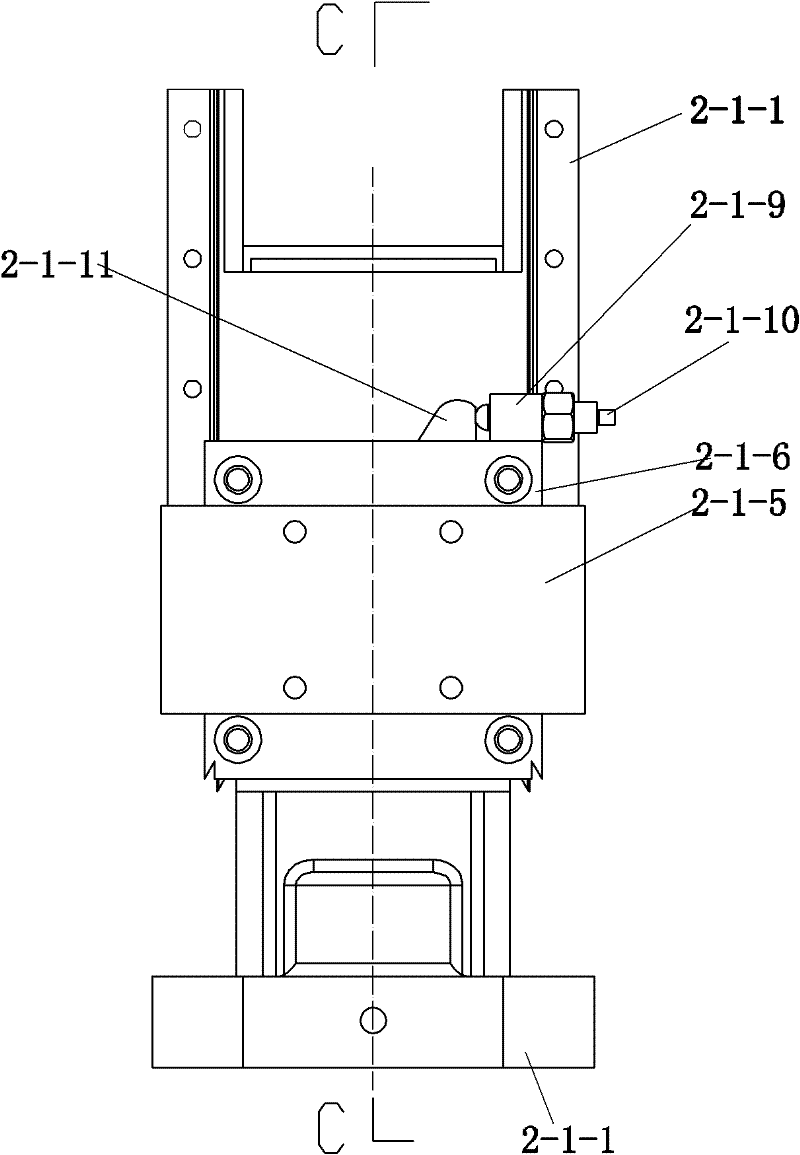

[0012] Embodiment 1 This embodiment includes a fuselage 10, a power mechanism 1, a toggle mechanism 2, a die 3, a workbench 4, a tablet pressing device 5, a tablet unloading device 6, an indexing device 7, and a radial direction that drives the workbench 4 to move. Feeding device 8 and air pressure system and lubricating oil system.

[0013] One side of the fuselage 10 is provided with a rail arm, and the workbench 4 is slidably connected to the rail arm. The radial feed device 8 has a speed reducer fixed on the rail arm, a radial feed servo motor is connected with the input shaft of the speed reducer, and the output shaft of the speed reducer drives the workbench 4 to move through the screw drive pair.

[0014] The punching die 3 includes an upper die 3-1 and a lower die 3-2, and the upper die 3-1 and the lower die 3-2 are dynamically connected by a guide post 3-11; the guide post 3-11 is fixed on the lower die 3 -2, the guide post 3-11 is inserted into the positioning hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com