Sundry separating device

A technology for separating devices and sundries, applied in the direction of solid separation, chemical instruments and methods, grids, etc., can solve the problems of weeds cannot be effectively screened, manual cleaning, etc., to achieve remote automatic or program control, to ensure continuous Sexuality, the effect of increasing cleaning driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

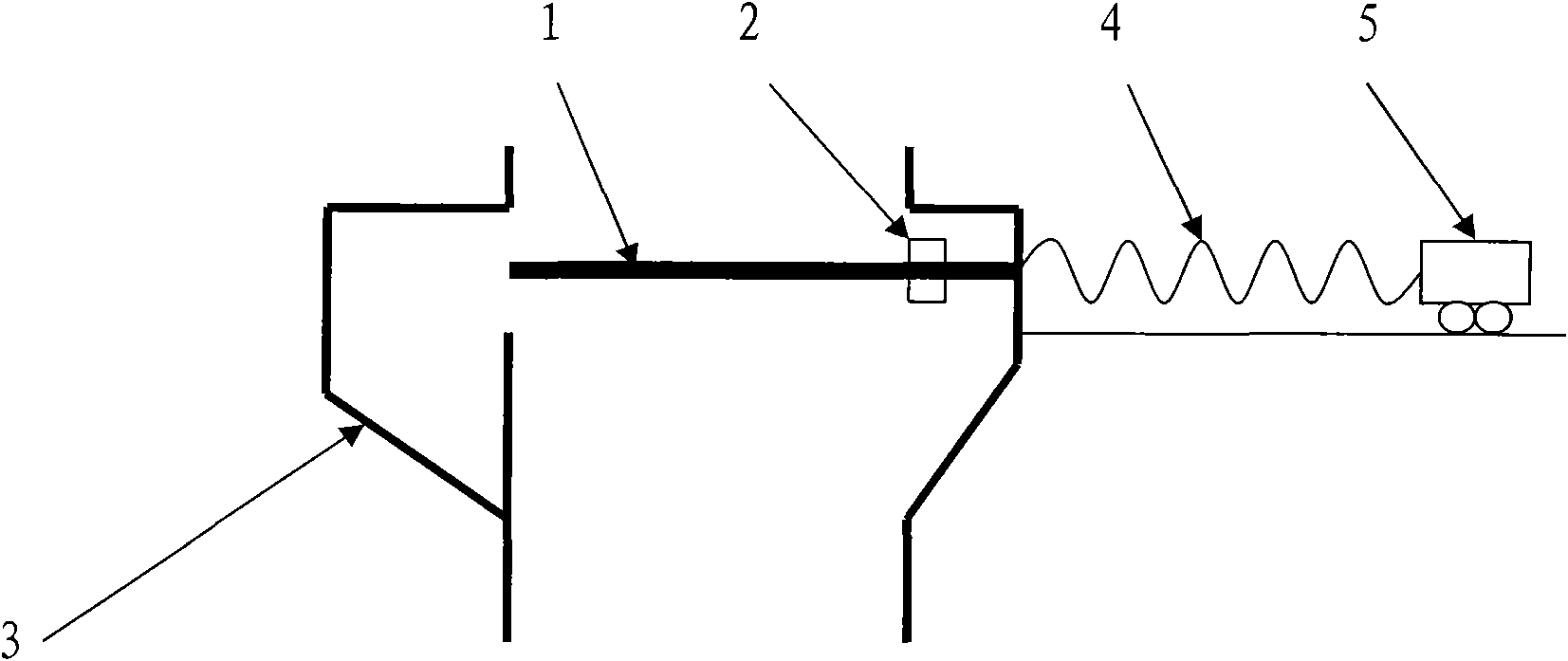

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail: debris separation device, by rod screen (1), cleaning mechanism (2), casing (3), transmission lead screw (4), electric actuator (5) composed of. The casing (3) of the cleaning device is formed after the logistics channel is deformed. The casing (3) is divided into two parts, and the interior of the logistics channel is divided into a cleaning area, and one side of the channel is a temporary storage area for sundries. A row of parallel bar screens (1) is fixedly installed on the upper part of the casing (3). A cleaning mechanism (2) that can move longitudinally along the screen is arranged on one side of the bar screens (1). The cleaning mechanism (2) and the transmission The leading screw (4) is connected, and the transmission leading screw (4) is connected with the electric actuator (5). A rod screen (1) is installed on the frame of the housing (3), and one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com