Rigid gear and flexible gear which are used for short-tube flexible-gear harmonic speed reducer and machining process thereof

A technology of harmonic reducer and processing technology, which is applied in the direction of gear transmission, components with teeth, belt/chain/gear, etc., and can solve the problem of coincidence reduction, flex spline tooth and rigid spline tooth meshing area Reduced, transmission stiffness and other issues, to achieve the effect of reducing the maximum stress, improving transmission stiffness, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

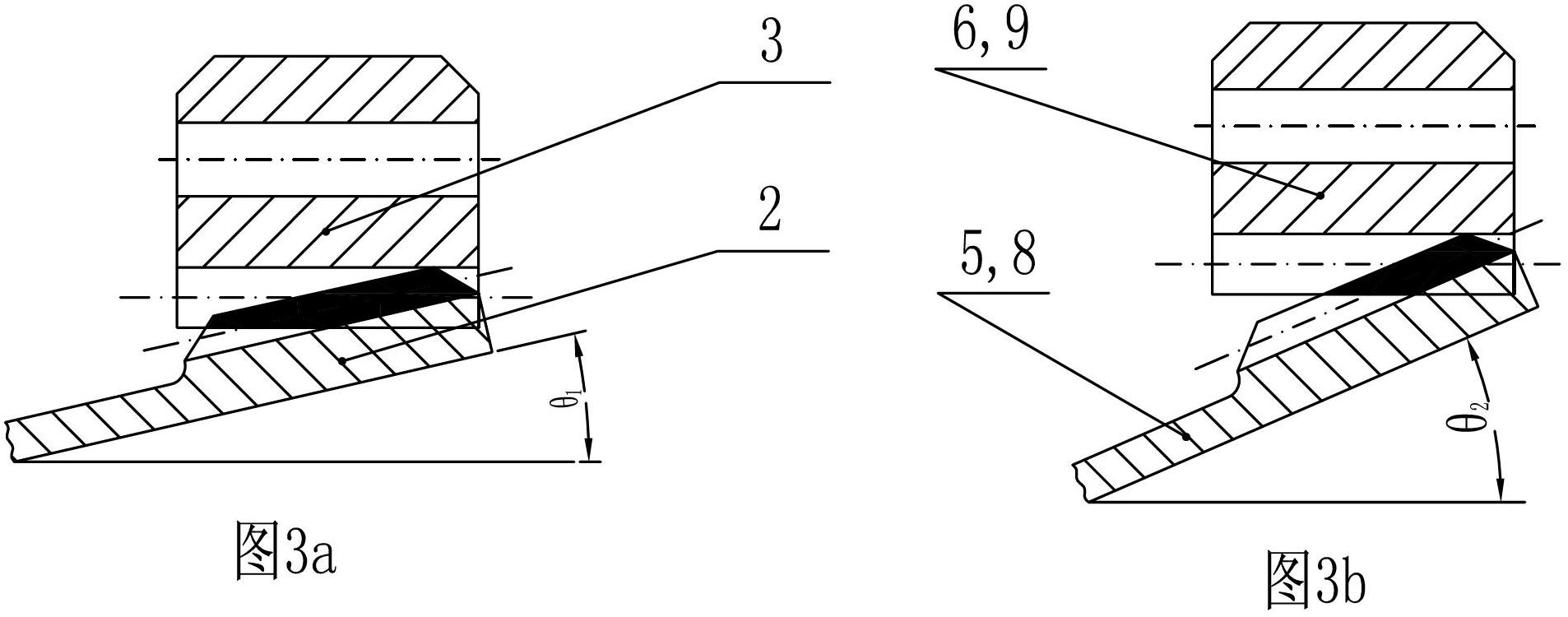

[0036] Specific implementation mode one: as Figure 10 with Figure 11 As shown, the internal teeth of the rigid wheels 6 and 9 of the short-tube flexible spline harmonic reducer described in this embodiment are gear teeth with an inclination angle α, and the inclination direction of the inclination angle α is different from the opening angle of the flexspline at the long axis Direction θ 2 Consistent, the inclination angle α is 0.1°~2°.

specific Embodiment approach 2

[0037] Specific embodiment two: the rigid wheel of the short-tube flexible wheel harmonic reducer described in this embodiment, the calculation formula of its internal tooth inclination angle α is: α = Σ j = 1 n c j ( b j 1 α j 1 + b j 2 α j 2 ) ;

[0038] where n is the number of meshing teeth in the meshing area near the major axis, c i is the weighting coefficient of the jth tooth, b j1 , b j2 is a weighting factor determined by the position of the pole radius of the...

specific Embodiment approach 3

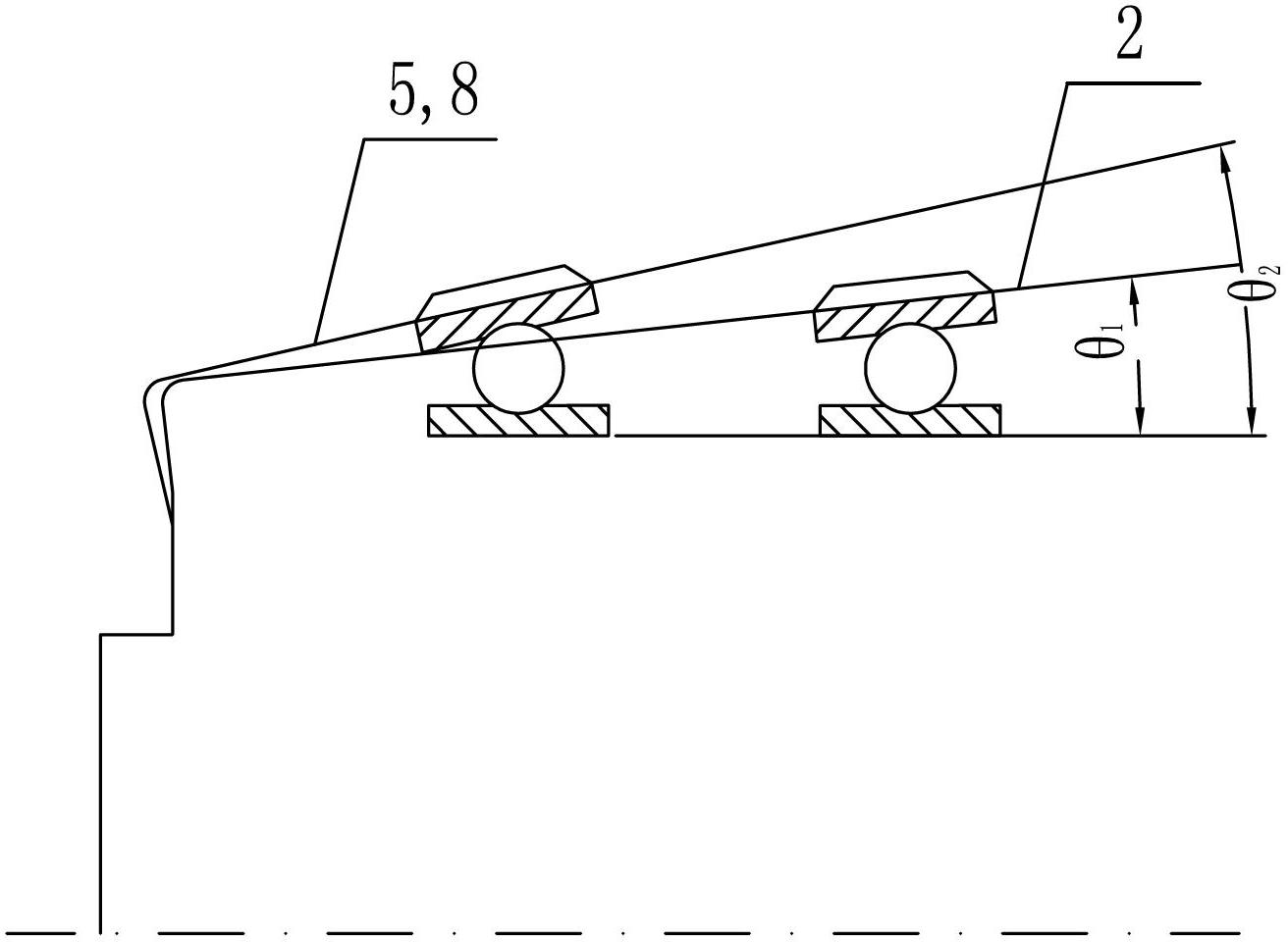

[0039] Specific implementation mode three: as Figure 4 , 6 , 11 and Figure 12 As shown, the flexspline of the short-tube flexspline harmonic reducer described in this embodiment, the external tooth profile of the flexspline 5 and 8 consists of two tooth profile curve segments and a tooth top straight segment l d Composition, the tops of the two tooth profile curves pass through the tooth top straight line l d connected together, each tooth profile curve segment is defined by the upper arc radius ρ a and the lower arc radius ρ f Connected with smooth transitions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com