Single-tangent double-circular-arc gear

A double arc and gear technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as complexity, increased design and manufacturing difficulties, and inability to meet gears, etc., to achieve gear teeth The structure is simple, it is good for storing lubricating oil, and the effect of large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

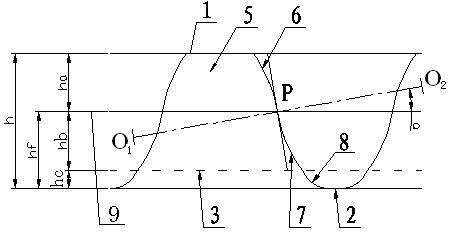

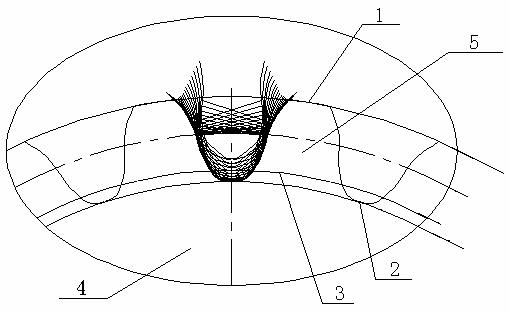

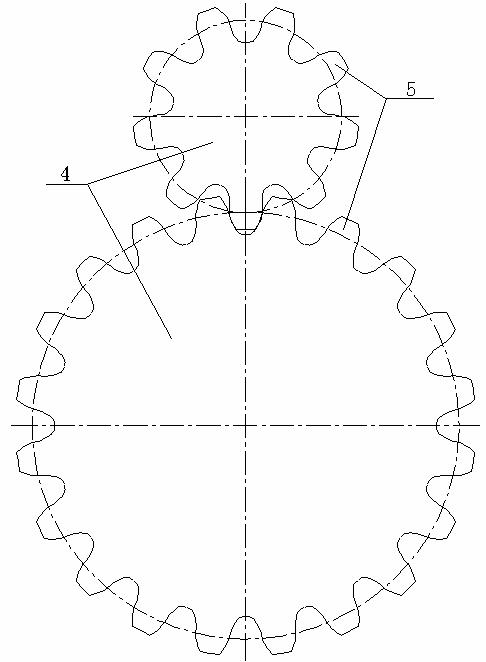

[0020] see figure 1 : A single-cut double arc gear, the gear 4 has a plurality of teeth 5, and each tooth 5 has two side surfaces, an addendum part and a dedendum part. Among them, the addendum part is formed by the addendum trace 1, and the addendum trace 1 is a straight line; the dedendum part is formed by the combination of the arc-shaped transition trace 8 and the dedendum trace 2, and the radius of the transition trace 8 is 0.5m (m represents the modulus, the same below), taking m=2 mm (the same below), then the radius of the transition trace 8 is 1 mm, and the dedendum trace 2 is a straight line; and on the same side there is another An arc-shaped convex trace 6 and an arc-shaped concave trace 7, the radius of the convex trace 6 is equal to the radius of the concave trace 7, and the radii of the convex trace 6 and the concave trace 7 are 1m respectively, then the convex trace The radii of the lines 6 and the concave traces 7 are 2 mm, respectively. One end of the conve...

Embodiment 2

[0022] see figure 1 : A single-cut double arc gear, the gear 4 has a plurality of teeth 5, and each tooth 5 has two side surfaces, an addendum part and a dedendum part. Among them, the addendum part is formed by the addendum trace 1, and the addendum trace 1 is a straight line; the dedendum part is formed by the combination of the arc-shaped transition trace 8 and the dedendum trace 2, and the radius of the transition trace 8 is 0.4m, take m=2 mm (the same below), then the radius of the transition trace 8 is 0.8 mm, and the dedendum trace 2 is a straight line; on the same side there is an arc-shaped convex trace 6 and a The arc-shaped concave trace 7, the radius of the convex trace 6 and the radius of the concave trace 7 are equal, and the radii of the convex trace 6 and the concave trace 7 are respectively 2m, then the radius of the convex trace 6 and the concave trace 7 4mm respectively. One end of the convex trace 6 is in contact with the addendum trace 1 of the addendum ...

Embodiment 3

[0024] see figure 1 : A single-cut double arc gear, the gear 4 has a plurality of teeth 5, and each tooth 5 has two side surfaces, an addendum part and a dedendum part. Among them, the addendum part is formed by the addendum trace 1, and the addendum trace 1 is a straight line; the dedendum part is formed by the combination of the arc-shaped transition trace 8 and the dedendum trace 2, and the radius of the transition trace 8 is 0.3m, take m=2 mm (the same below), then the radius of the transition trace 8 is 0.6 mm, and the dedendum trace 2 is a straight line; on the same side there is an arc-shaped convex trace 6 and a The arc-shaped concave trace 7, the radius of the convex trace 6 and the radius of the concave trace 7 are equal, the radius of the convex trace 6 and the concave trace 7 is 3m respectively, then the radius of the convex trace 6 and the concave trace 7 6mm respectively. One end of the convex trace 6 is in contact with the addendum trace 1 of the addendum part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com