Corrugated pipe facilitating cleaning of gaps between corrugations

A corrugated pipe and cleaning technology, applied in the field of corrugated pipes, can solve the problems of low cleaning efficiency, affecting the appearance, affecting the expansion and contraction effect of corrugated pipes, etc., to achieve the effect of ensuring cleanliness and strong cleaning power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

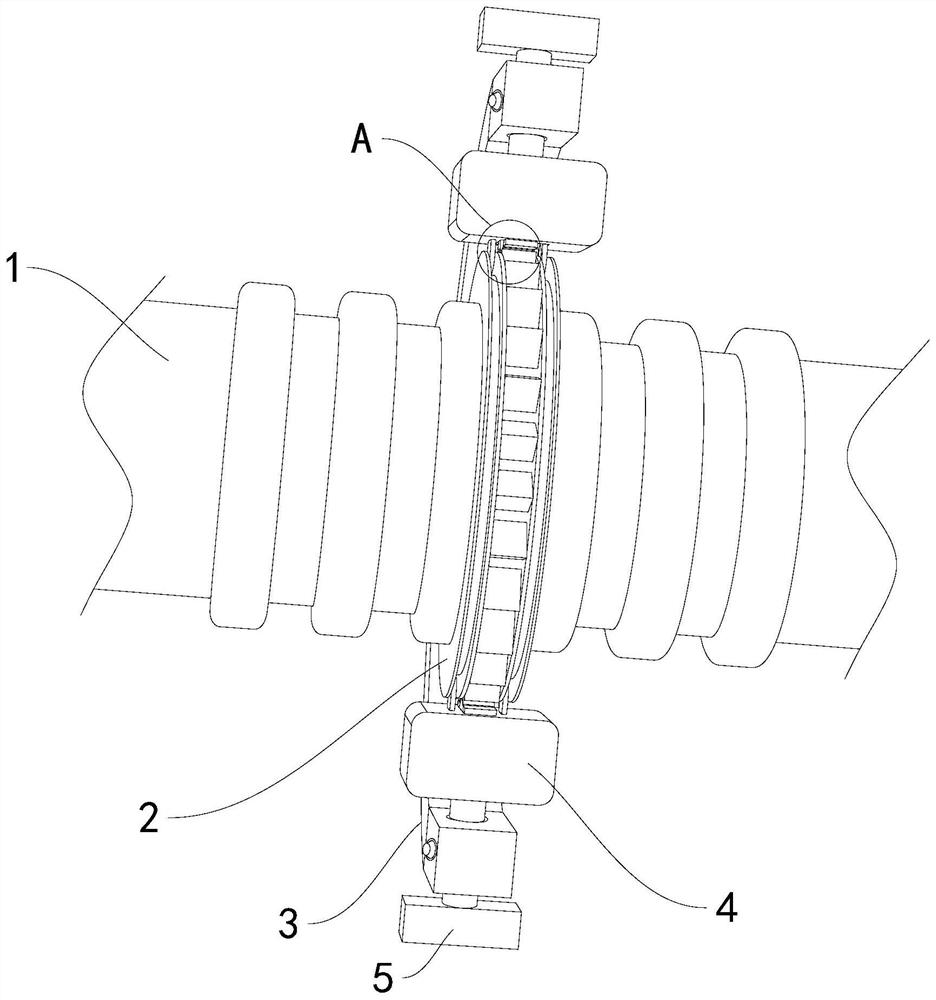

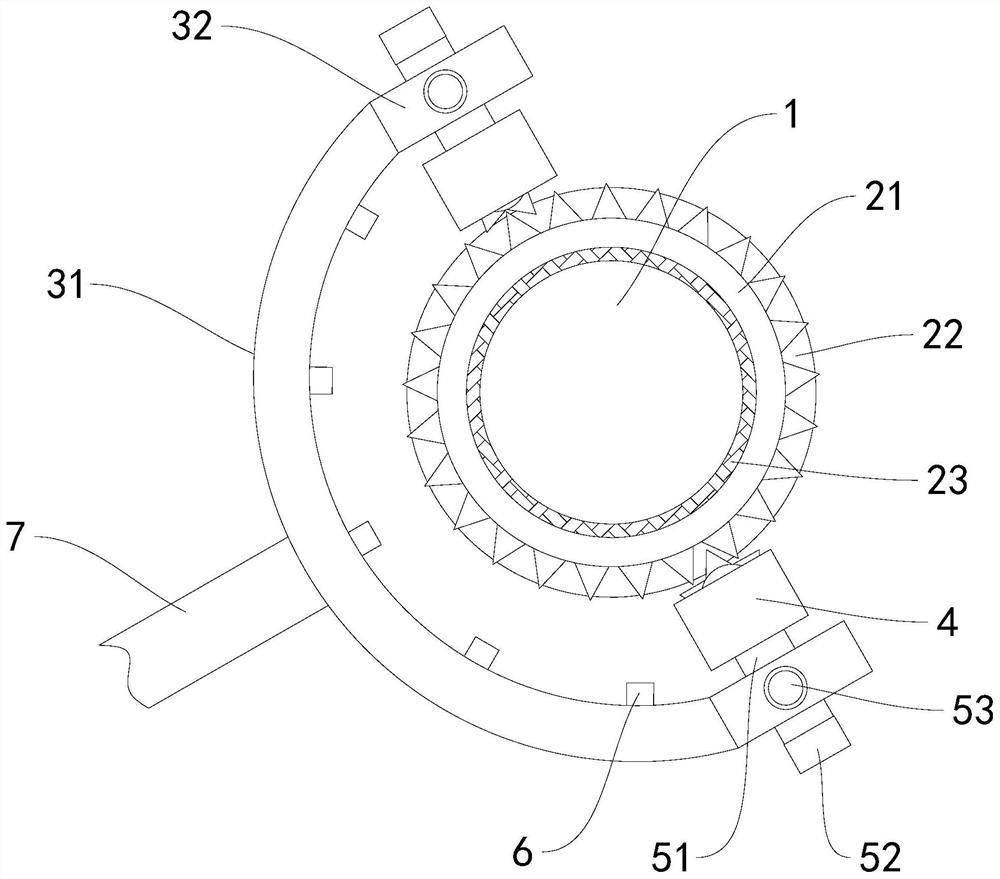

[0042] see Figure 1-6 , a bellows for easy cleaning of gaps between lines, comprising a bellows main body 1, the outer end of the bellows main body 1 is sleeved with a cleaning main ring 2, and the upper and lower ends of the cleaning main ring 2 are meshed with a power box 4, and the cleaning The outer side of the main ring 2 is provided with a cleaning secondary ring 3, and both ends of the cleaning secondary ring 3 are drilled with movable holes, a distance adjustment device 5 is connected between the power box 4 and the movable hole, and the inner end of the cleaning secondary ring 3 is fixedly connected with a A plurality of dust suction secondary pipes 6, the end of the cleaning secondary ring 3 away from the dust suction secondary pipe 6 is fixedly connected with a dust suction main pipe 7, and the dust suction secondary pipe 6, the cleaning secondary ring 3 and the dust suction main pipe 7 are connected in sequence.

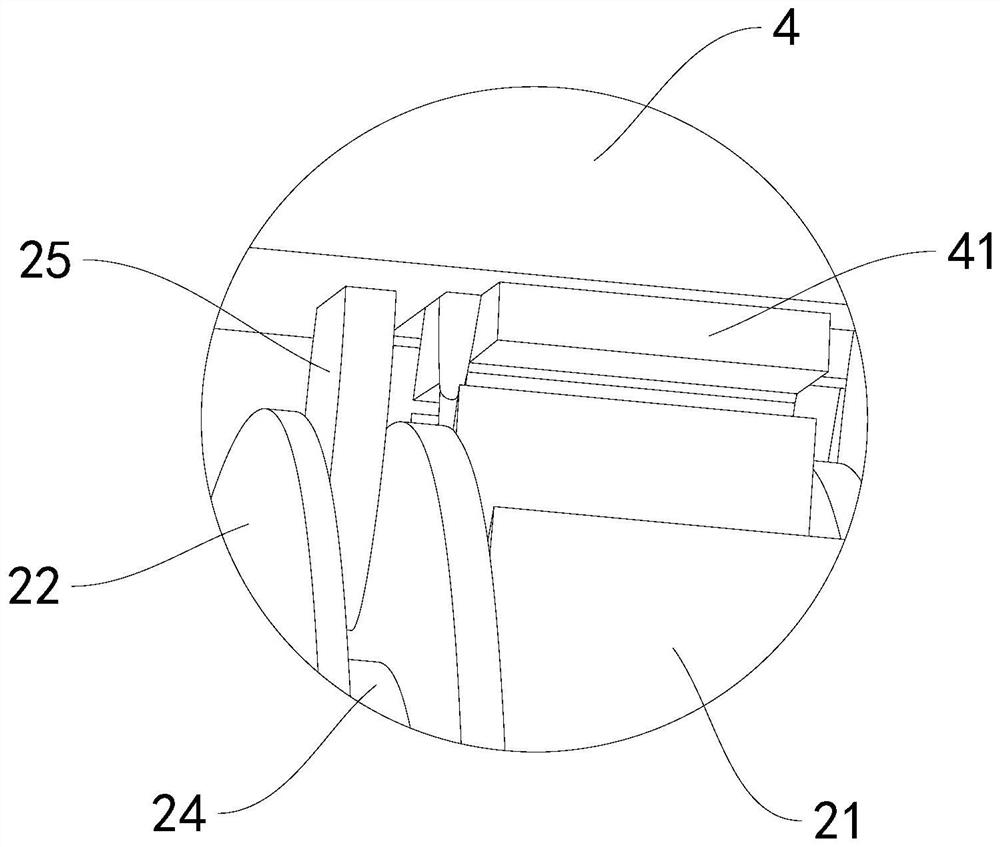

[0043] see Figure 2-3 , the cleaning main ring 2...

Embodiment 2

[0048] see Figure 7-10 , the middle part of the outer gear ring body 21 is dug with a first negative pressure groove 211, and the inner bottom of the first negative pressure groove 211 is dug with a plurality of annularly distributed cleaning holes 212, and the middle part of the lower end of the power box 4 is equipped with a cleaning hole. 212 corresponds to the cleaning suction pipe 412, and the cleaning suction pipe 412 is connected with the dust suction auxiliary pipe 6. The middle part of the gear 41 has a second negative pressure groove 411 that is not easy to affect the cleaning suction pipe 412 dust suction. When the suction pipe 412 corresponds to the cleaning hole 212, a negative pressure is generated, which can effectively suck out the dust between the outer gear ring body 21 and the bellows body 1, and at the same time cooperate with the suction of the dust brushed out by the long-haired brush 23, and the double cleaning effect inside and outside, so that The cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com