Ecotype prefabricated building bock bank revetment

An eco-type, block technology, applied in piers, bank walls, embankments, etc., can solve the problems of neglecting rivers, river water pollution, destroying river ecological processes, etc., to improve negative effects, simple and fast construction, and prevent river bank erosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

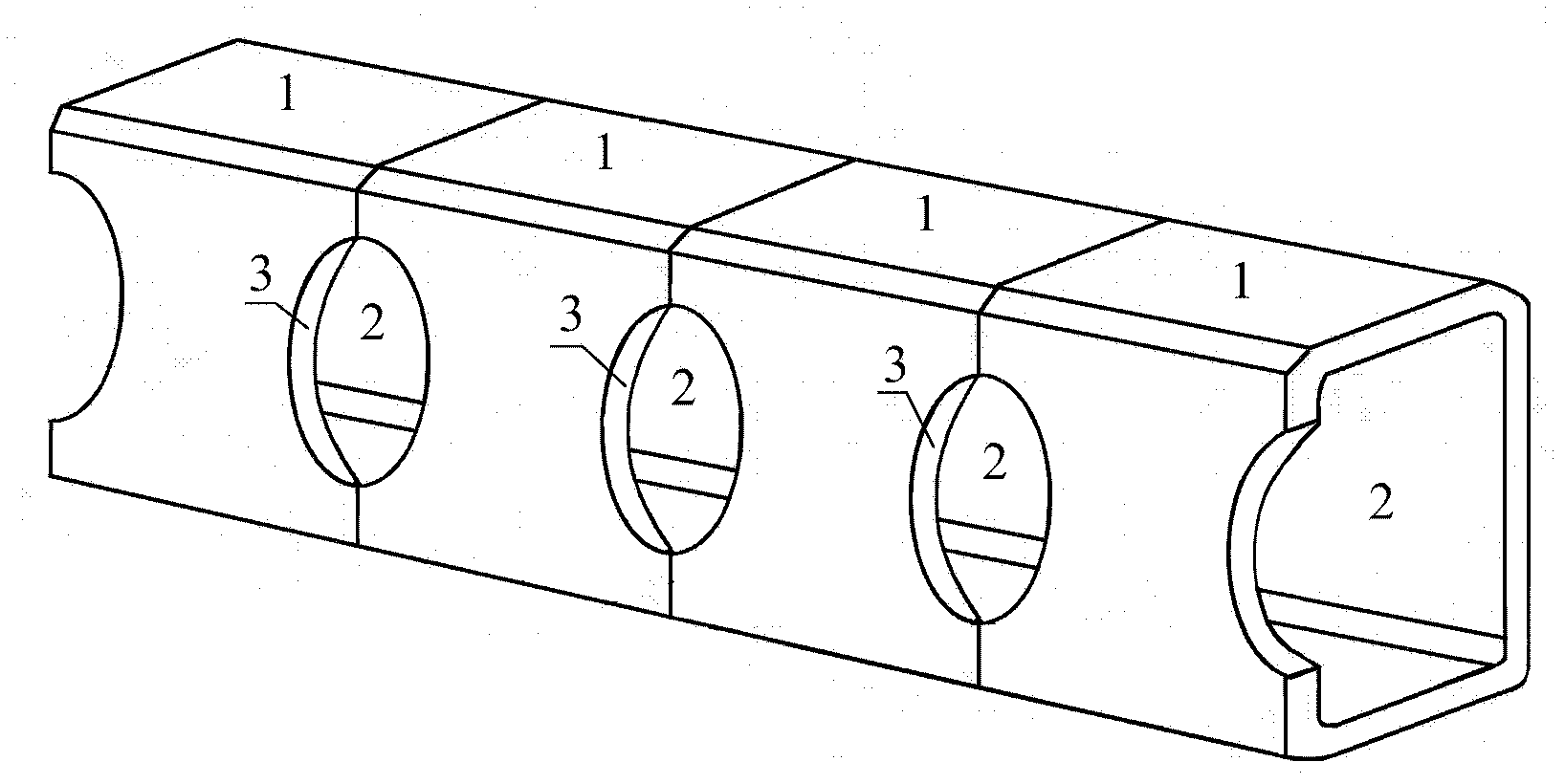

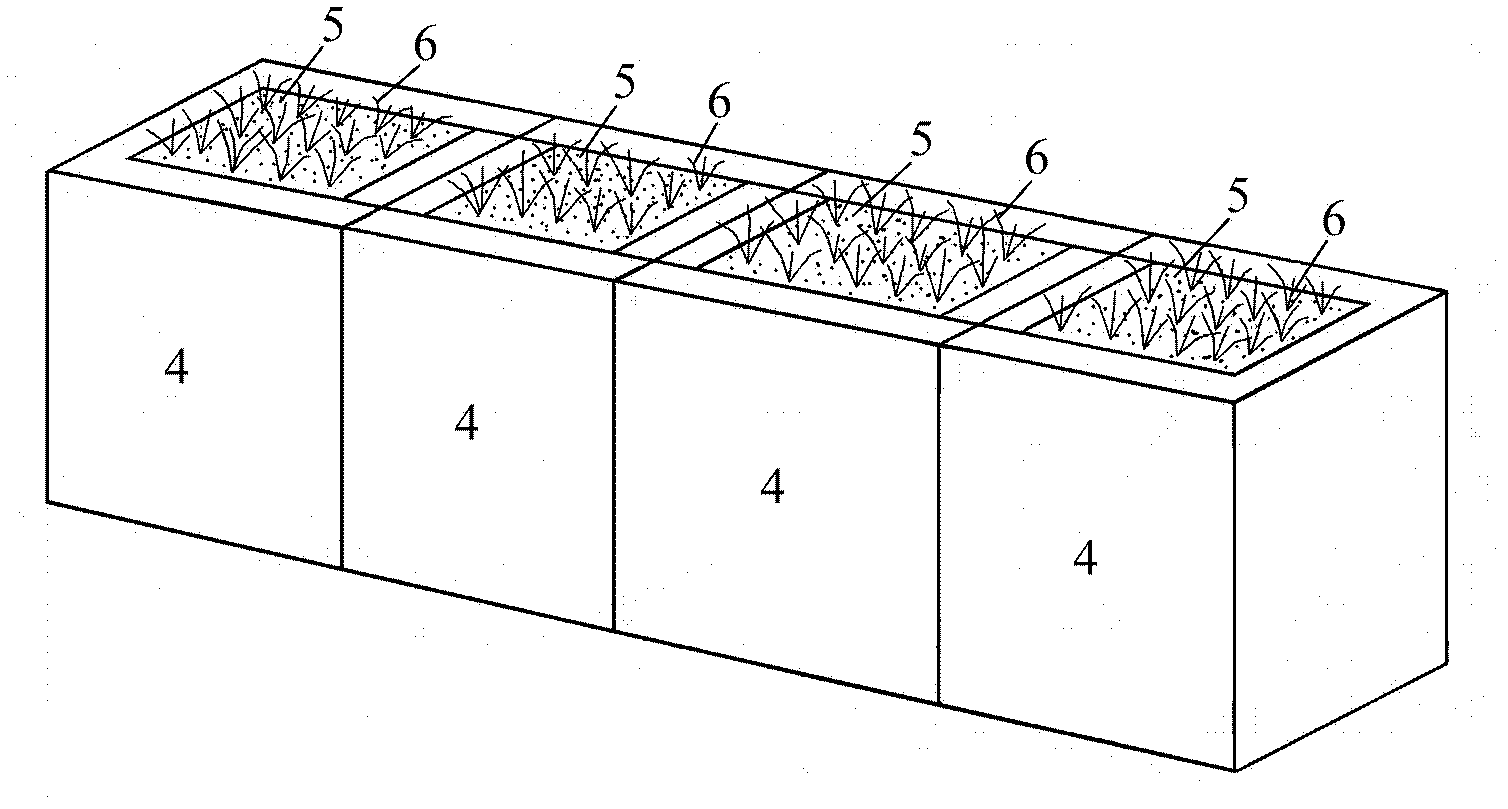

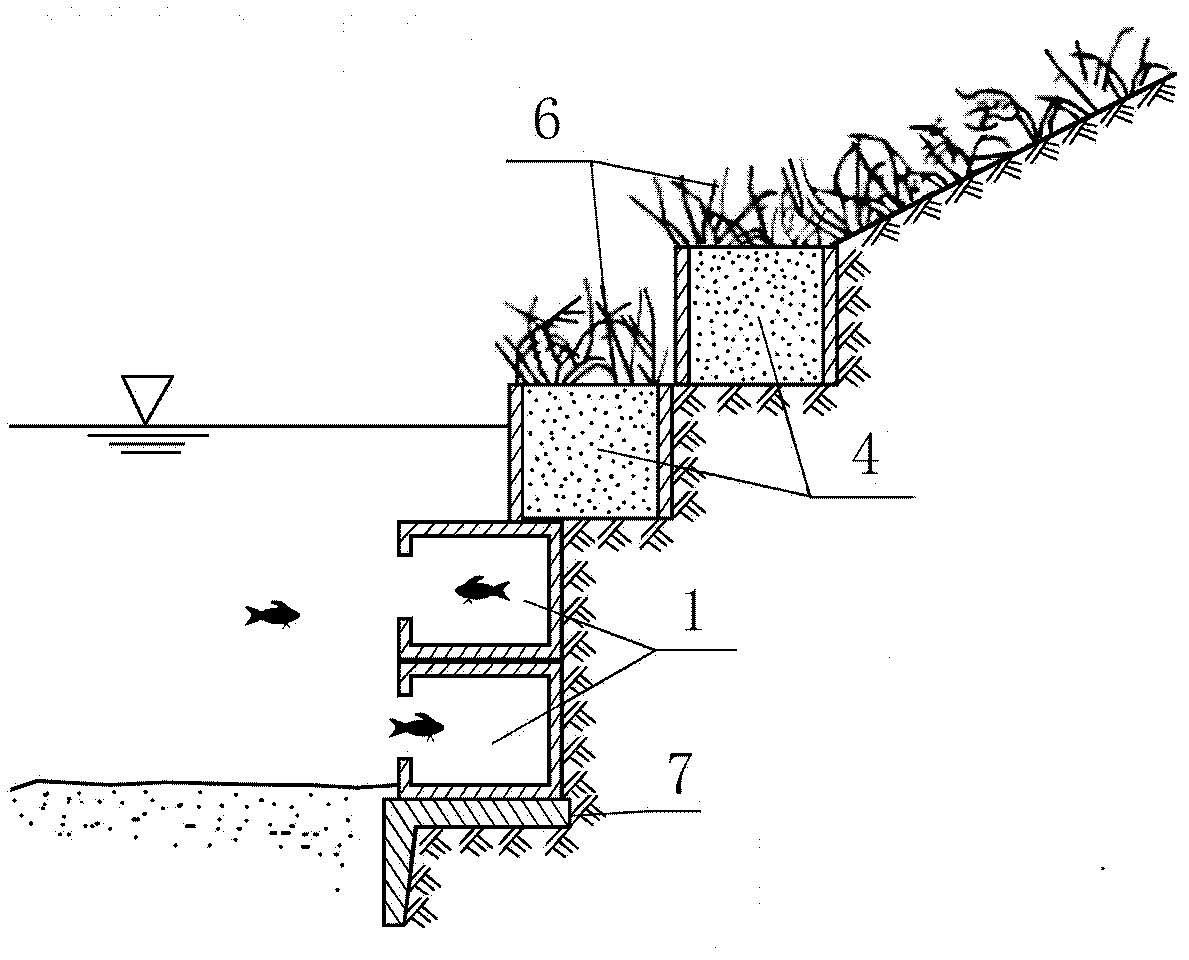

[0017] see figure 1 , figure 2 and image 3 , an ecological prefabricated block bank revetment for ordinary rivers, the base 7 is cast in-situ with mortar block stone or concrete, the bottom elevation of the base 7 goes deep below the design minimum scour line, and has a certain safety margin to ensure the safety of the revetment . A fish nest type cavity block 1 and a plant type cavity block 4 are built on the base 7 . During masonry, fish nest type cavity blocks 1 are used for the underwater part submerged all the year round, and plant type cavity blocks 4 are used for the above water part. The fish nest type cavity block 1 can be built into a vertical or stepped revetment pattern, so that fish can enter and exit from the hole conveniently. But plant type cavity block 4 should be built into stepped revetment pattern, so that plant plant above the step.

Embodiment 2

[0019] see figure 1 , figure 2 and Figure 4 , an improved structure for revetment of urban rivers, especially the rivers in the old urban areas with many buildings, restricted by the buildings on both sides, the cross section is often rectangular. Although the rectangular section saves land, it is poor in ecology, ornamental and hydrophilic. For this reason, some concrete cavity prefabricated blocks can be arranged along the river banks on the water side of the original concrete or masonry revetment 8. The fish nest-type cavity block 1 arranged in the lower part provides a habitat for various wild aquatic organisms; the plant-type cavity block 4 arranged in the upper part can plant aquatic plants 10 . Aquatic plants can absorb and transfer pollutants in river water and inhibit the growth and development of bath plants, which play an important role in controlling eutrophication in river water and improving water quality. In addition, plant-type cavity blocks 4 can be set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com