Permanent magnet speed governor with fixed magnetic gap

A permanent magnet speed governor and fixed magnetic technology, applied in electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of high power consumption of magnetic circuit regulators, poor torque transmission capacity, waste of rare earth resources, etc., to save Installation space, improved torque transmission capacity, and the effect of saving rare earth materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

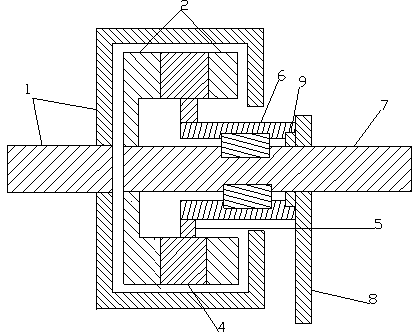

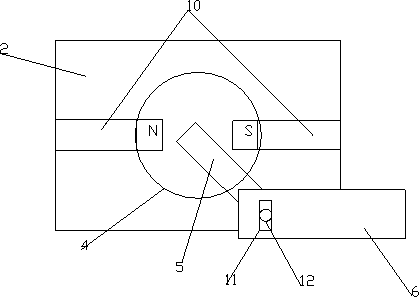

[0027] A permanent magnet governor with a fixed magnetic gap, such as figure 1 , 2 As shown, it includes a cylindrical conductor rotor 1 and a permanent magnet rotor inside. The permanent magnet rotor includes a driven shaft 7 and at least one rotatable permanent magnet 4 arranged circumferentially around the driven shaft 7. The rotatable permanent magnet 4 is cylindrical and has an N pole and an S pole along the diameter direction, and the rotatable permanent magnet 4 is perpendicular to the driven shaft 7 . Both sides of the rotatable permanent magnet 4 are wrapped with a magnetizer 2, and the two magnetizers 2 are separated by a non-magnetizer 10. The rotatable permanent magnet 4 is connected with the driven shaft 7 through the magnetizer 2 on one side, and the rotatable permanent magnet One end of 4 is provided with a magnetic circuit adjuster, and the magnetic circuit adjuster is used to rotate the rotatable permanent magnet 4, adjust its magnetic pole direction and then...

Embodiment 2

[0029] A permanent magnet governor with a fixed magnetic gap, such as image 3 , 4 As shown, the rotatable permanent magnet 4 is parallel to the driven shaft 7, and other structures are the same as in the first embodiment.

Embodiment 3

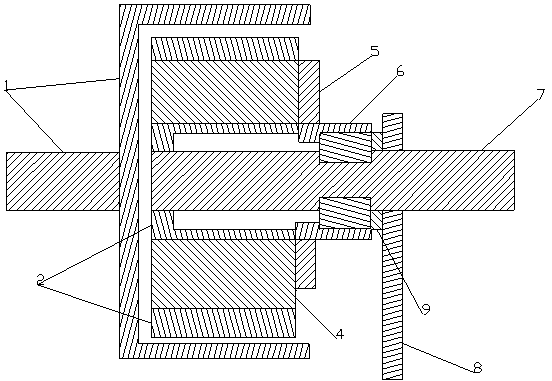

[0031] A permanent magnet governor with a fixed magnetic gap, such as Figure 5 , 6As shown, it includes a cylindrical conductor rotor 1 and a permanent magnet rotor inside. The permanent magnet rotor includes a driven shaft 7 and at least one rotatable permanent magnet 4 arranged circumferentially around the driven shaft 7. The rotatable permanent magnet 4 is cylindrical and has an N pole and an S pole along the diameter direction, and the rotatable permanent magnet 4 is perpendicular to the driven shaft 7 . Both sides of the rotatable permanent magnet 7 are wrapped with a magnetizer 2, and the two magnetizers 2 are separated by a non-magnetizer 10. The rotatable permanent magnet 4 is connected with the driven shaft 7 through the magnetizer 2 on one side, and the rotatable permanent magnet One end of 4 is provided with a magnetic circuit adjuster, and the magnetic circuit adjuster is used to rotate the rotatable permanent magnet 4, adjust its magnetic pole direction and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com